Lithium bismuthate/nickel hydroxide secondary alkaline battery and preparation method thereof

A technology of nickel hydroxide and alkaline batteries, which is applied in the field of electrochemical energy storage, can solve problems that have not been seen, and achieve the effects of large capacity, environmental friendliness, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) 40mmol Li 2 SO 4 ·H 2 O, 0.01gPVP surfactant and 40ml deionized water are added in the 100mL there-necked flask, then 8mmol NaBiO 3 2H 2 O was added to the above solution, and after stirring at room temperature for 30 min, the mixed solution was refluxed at 100° C. for 24 h. After the reaction was completed, the product was washed with distilled water and ethanol several times until the product pH=7. Then the solid product was dried at 100°C to constant weight to obtain lithium bismuthate material.

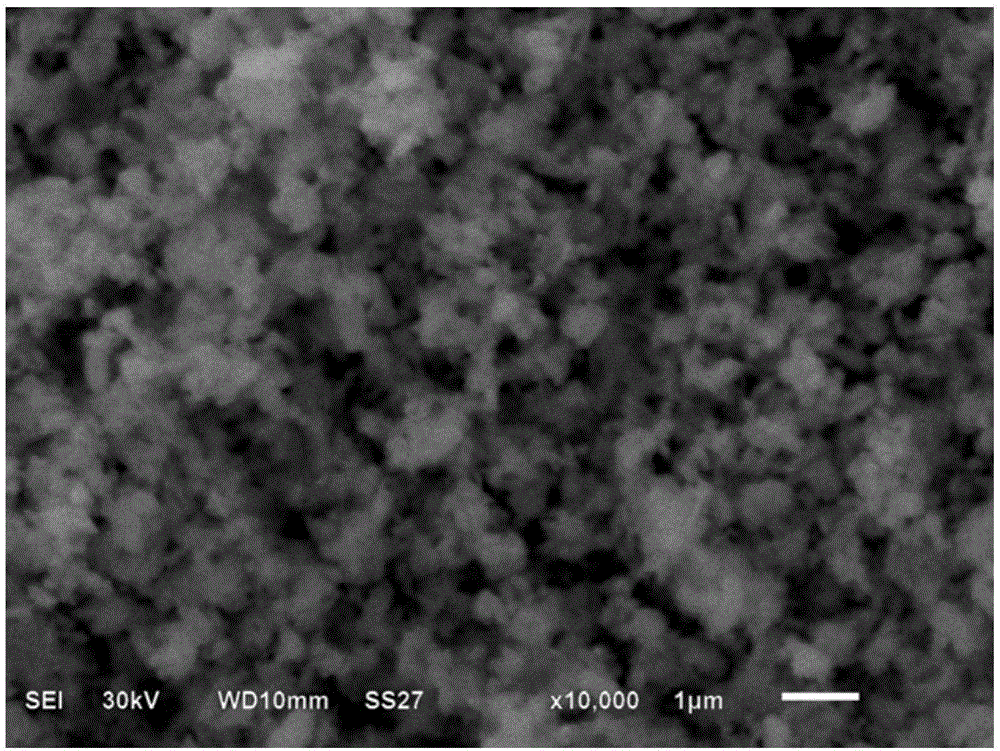

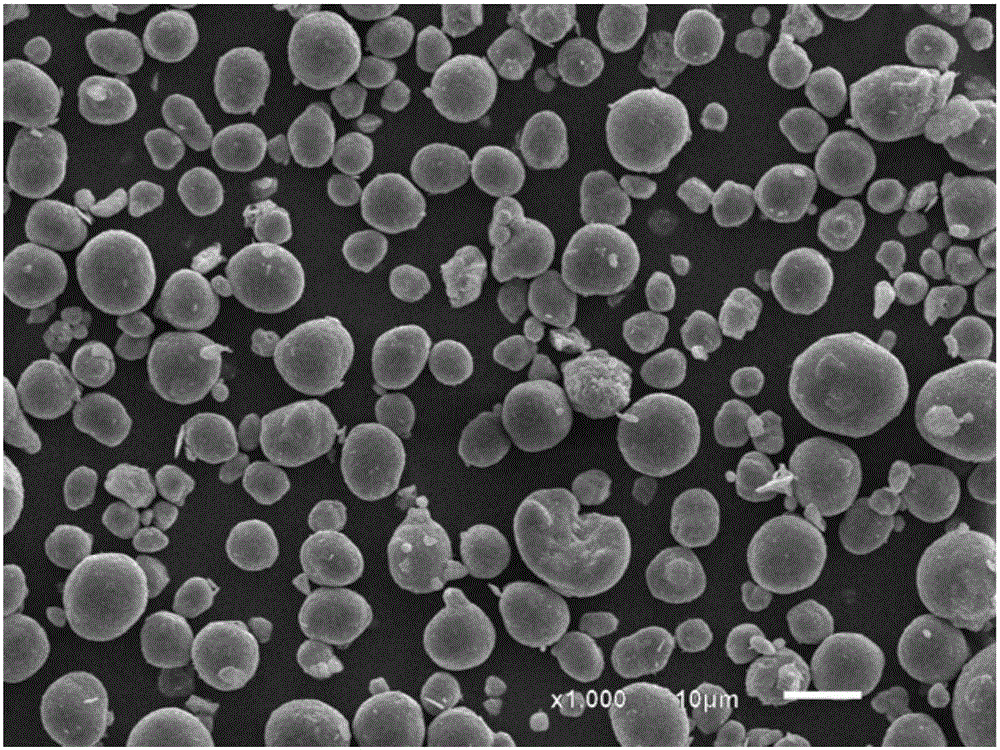

[0048] (2) Adopt the JEOLJEM-3010 type scanning electron microscope to test the lithium bismuth oxide material prepared in embodiment 1 and the nickel hydroxide material used in embodiment 1~5 respectively, as figure 1 As shown, the prepared lithium bismuth oxide material is composed of nanoparticles stacked into irregular aggregates. Such as figure 2 As shown, the nickel hydroxide material used is composed of microspheres with a diameter of about 5-15 μm.

[00...

Embodiment 2

[0055] (1) Weigh 40mmol LiOH·H 2 O was dissolved in 50 mL of deionized water, and then pressed by LiOH·H 2 O and NaBiO 3 2H 2 O is a molar ratio of 3:1, a certain amount of NaBiO 3 2H 2 O was added to the above solution, stirred at room temperature for 30 min, and then the mixed solution was transferred to a high-pressure reactor with a volume filling rate of 0.4. The reactor was placed at 130°C, hydrothermally treated for 48 h, and then cooled to room temperature. Then the hydrothermal product is subjected to solid-liquid separation and washed until neutral, and then the solid is dried at 100°C to constant weight to prepare lithium bismuthate.

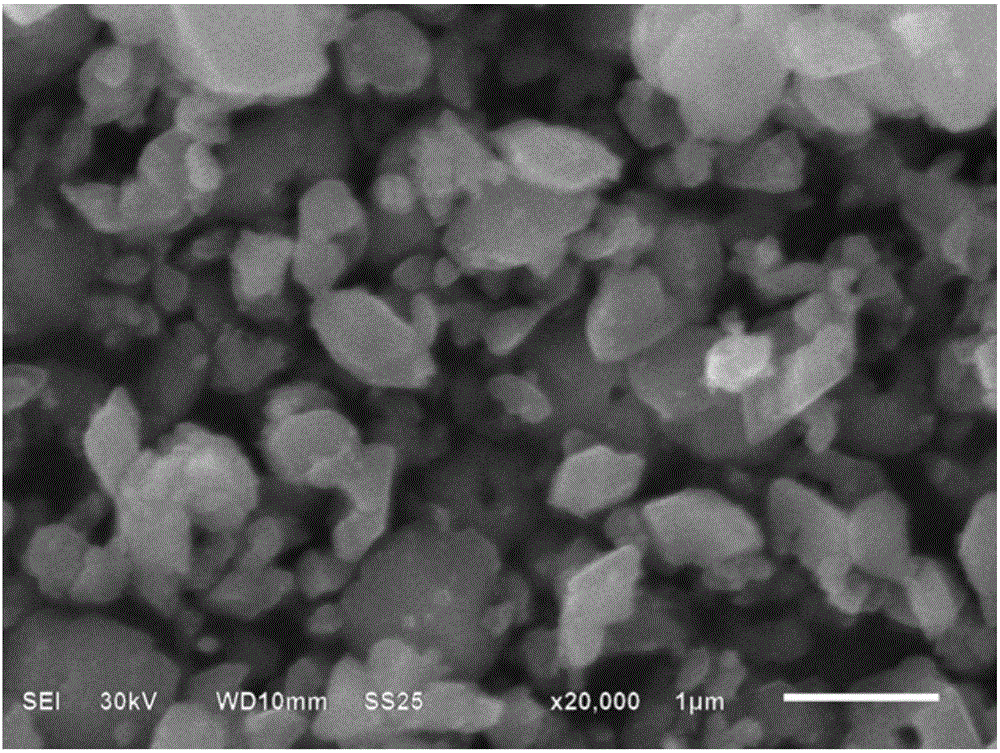

[0056] (2) Adopt the JEOLJEM-3010 type scanning electron microscope to test the lithium bismuth oxide material prepared by embodiment 2, such as image 3 As shown, the lithium bismuthate material is composed of particles with a size of about 0.2-0.8 μm.

[0057] (3) step with (3) in embodiment 1.

[0058] (4) Put the prepared l...

Embodiment 3

[0061] (1) Weigh 40mmol LiOH·H 2 O was dissolved in 50 mL of deionized water, and then pressed by LiOH·H 2 O and NaBiO 3 2H 2 O is a molar ratio of 4:1, a certain amount of NaBiO 3 2H 2 O was added to the above solution, stirred at room temperature for 30 min, and then the mixed solution was transferred to an autoclave with a volume filling rate of 0.5, and the autoclave was placed at 120°C, hydrothermally treated for 60 h and then cooled to room temperature. Then the hydrothermal product is subjected to solid-liquid separation and washed until neutral, and then the solid is dried at 100°C to constant weight to prepare lithium bismuthate.

[0062] (2) Adopt XRD-6000 type X-ray diffractometer to test the lithium bismuth oxide material prepared by embodiment 3, as Figure 6 As shown, the sample has obvious characteristic peaks at 2θ=19°, 20°, 28°, 33°, 35°, 42°, 46°, 51° and other positions, and the standard card (JCPDS No.52-0348 ) are consistent, and the corresponding cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com