BiOCl material preparation method and application of BiOCl material

A raw material and size technology, applied in the field of BiOCl material preparation, can solve problems such as high cost and complex synthesis process, and achieve the effects of mild process conditions, simple preparation process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 2mmol sodium bismuthate, 1mmol metal bismuth powder, 2mmol potassium chloride, and 0.01mmol polyvinylpyrrolidone are mixed uniformly to obtain a raw material mixture; the raw material mixture and corundum grinding balls are added to the ball mill tank at a mass ratio of 1:50, Nitrogen was introduced, ball milling was carried out at a speed of 1500rpm for 8 hours, the mixture after ball milling was heat-treated at a constant temperature at 200°C for 5 hours, and then the heat-treated product was washed with deionized water and absolute ethanol to remove impurities, and solid-liquid separation was carried out by filtration. Finally, the filtered solid product was vacuum-dried at 100° C. for 12 h to prepare the BiOCl material.

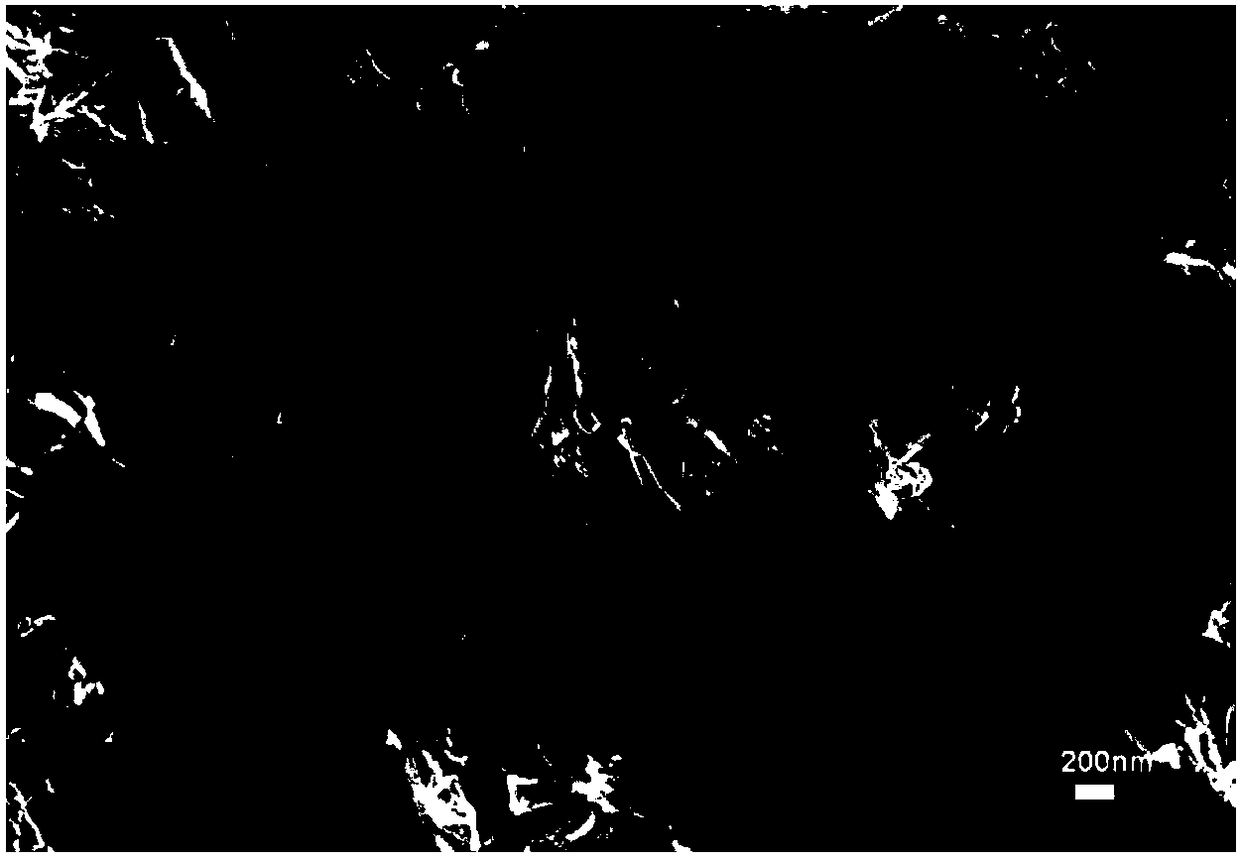

[0031] (2) Adopt JEOLJEM-3010 type scanning electron microscope to test the BiOCl material prepared in embodiment 1, such as figure 1 As shown, the BiOCl material is composed of stacked nanosheets with a maximum plane size of 2 μm and a thickne...

Embodiment 2

[0033] (1) Mix 2mmol potassium bismuthate, 2mmol sodium sulfite powder, 1mmol zinc chloride, and 0.005mmol sodium dodecylbenzenesulfonate to obtain a raw material mixture; add the raw material mixture and corundum grinding balls in a mass ratio of 1:100 In the ball mill tank, argon gas was introduced, and the ball mill was carried out at a speed of 1500rpm for 6 hours. The mixture after ball milling was heat-treated at a constant temperature of 300°C for 4 hours, and then the heat-treated product was washed with deionized water and absolute ethanol to remove impurities, and filtered Solid-liquid separation was performed, and finally the filtered solid product was dried at 110° C. for 8 hours to prepare a BiOCl material.

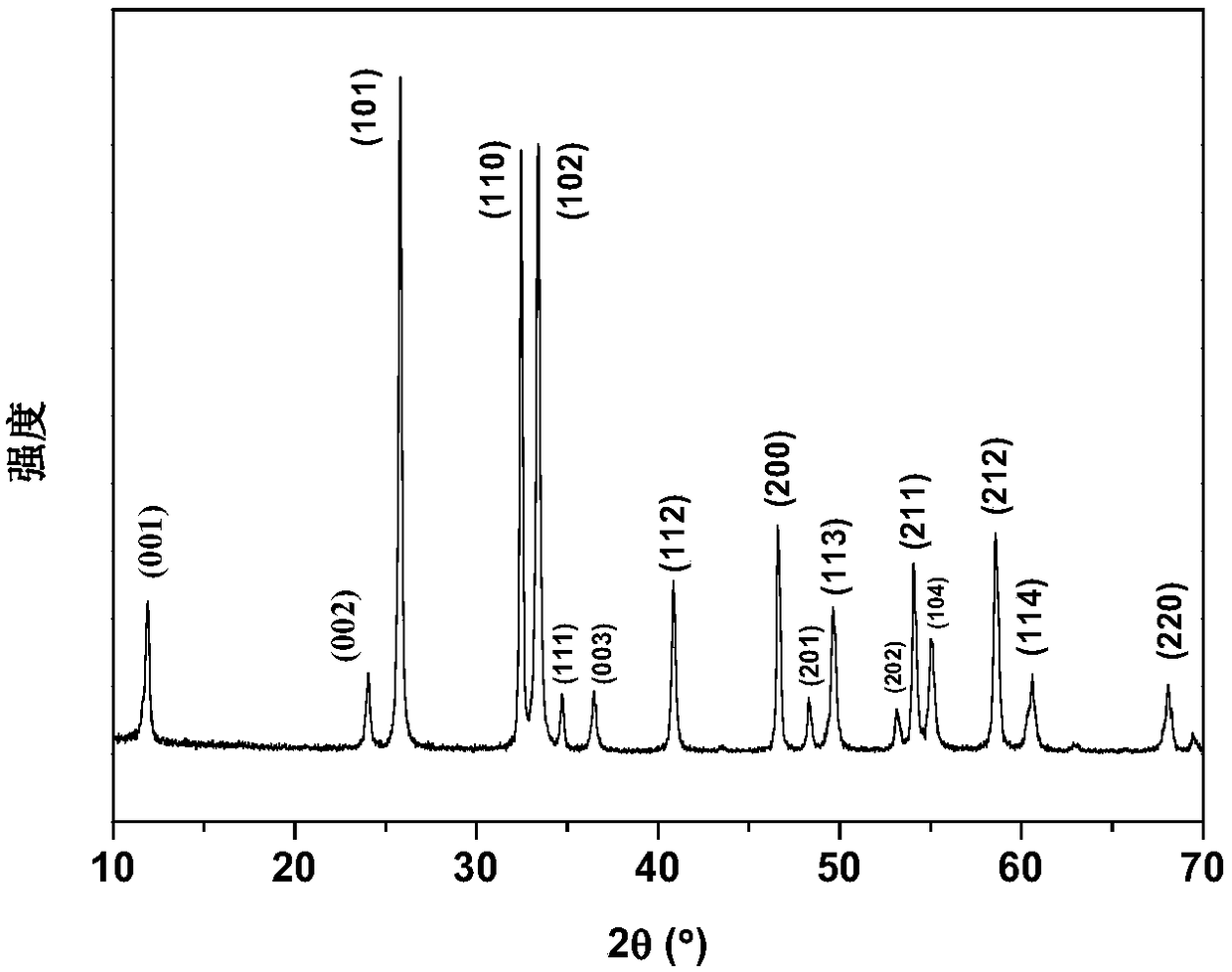

[0034] (2) adopt XRD-6000 type X-ray diffractometer to test the BiOCl material prepared by embodiment 2, such as figure 2 As shown, the crystal phase of the obtained BiOCl product is pure, without other impurity peaks, and the crystallinity is good.

Embodiment 3

[0036] (1) Mix 2mmol sodium bismuthate, 1mmol activated carbon powder, 3mmol sodium chloride, and 0.02mmol cetyltrimethylammonium bromide to obtain a raw material mixture; mix the raw material mixture and stainless steel balls in a mass ratio of 1:60 Add it into a ball mill tank, feed nitrogen, and carry out ball milling at a speed of 1000rpm for 9h. The mixture after ball milling was heat-treated at a constant temperature of 250°C for 7h, and then the heat-treated product was washed with deionized water and absolute ethanol to remove impurities. Solid-liquid separation was performed by filtration, and finally the solid product obtained by filtration was vacuum-dried at 90° C. for 10 h to prepare a BiOCl material.

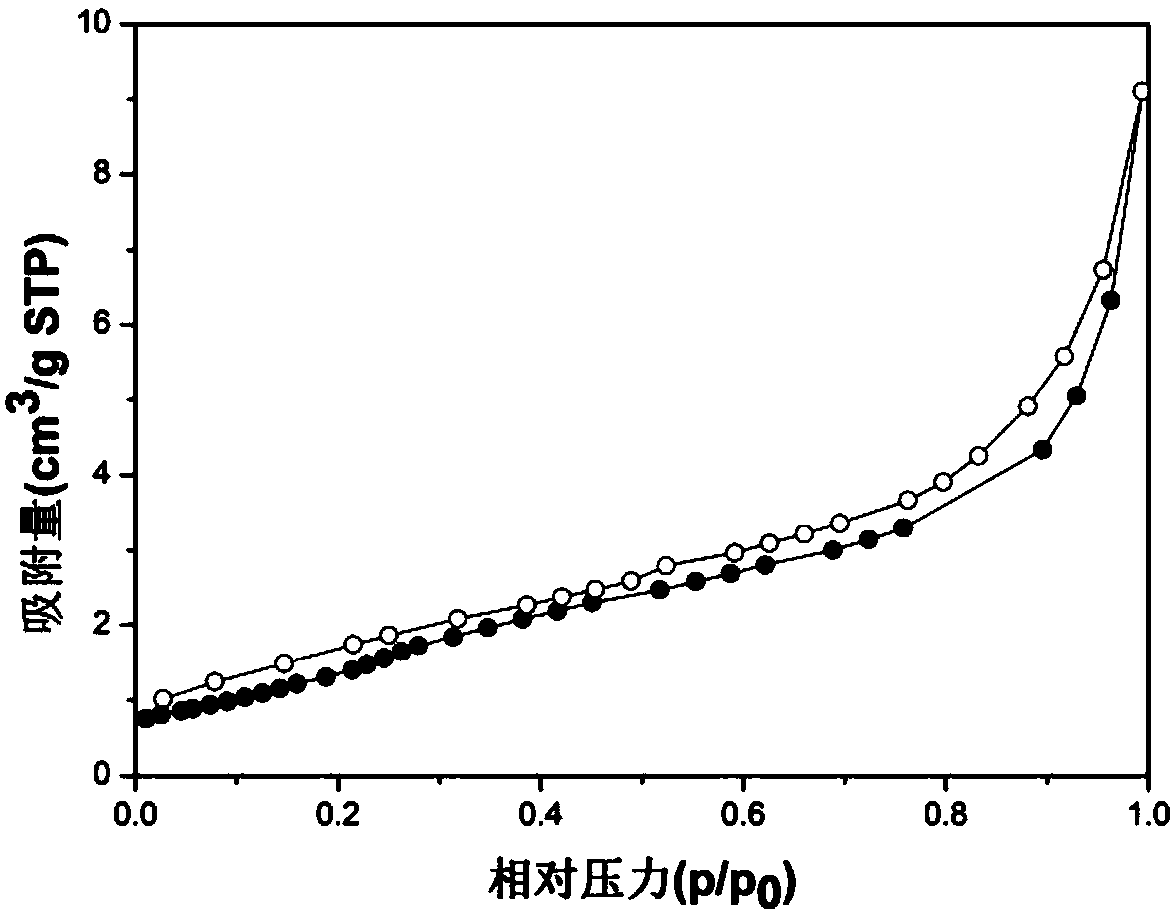

[0037](2) Adopt TriStar II 3020 type specific surface area and pore size distribution instrument to test the sample material obtained in embodiment 3, as image 3 As shown, the specific surface area of BiOCl material is 20.4m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com