Copper bismuthate/ tungsten oxide composite film material, preparation method and application thereof in preparation of methane by photocatalytic carbon dioxide

A composite film, tungsten oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrocarbon production from carbon oxides, etc., can solve the problem of low solar energy utilization and narrow light response range. and other problems, to achieve the effect of stable structure, wide application prospects and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

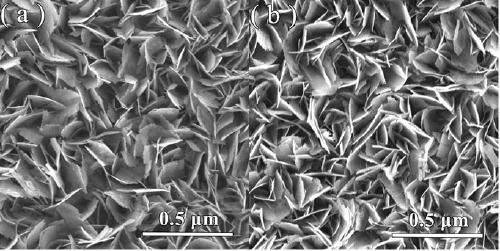

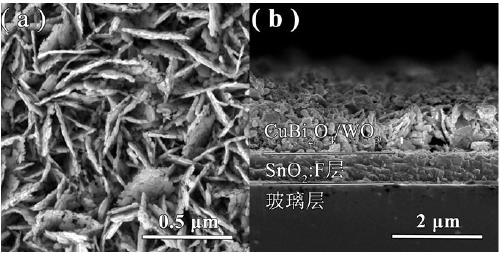

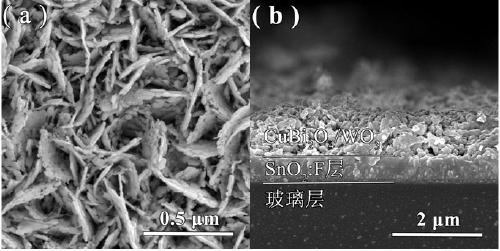

Image

Examples

Embodiment 1

[0031] A CuBi 2 o 4 / WO 3 The preparation method of composite film material, it specifically comprises the steps:

[0032]1) Pretreatment of FTO conductive glass: Soak 1×2cm FTO conductive glass in ethanol and deionized water in sequence, place it in a 400W ultrasonic cleaner for ultrasonic cleaning for 30min, remove the FTO conductive glass, dry it with nitrogen, and place it in 150W After 30 minutes of irradiation under a long-arc mercury lamp, weigh and record the mass of FTO glass as m 0 ;

[0033] 2) WO 3 Seed layer preparation: Weigh 2.0 g of tungstic acid into 50 mL of hydrogen peroxide, heat to 60°C and reflux and stir for 1.5 hours to obtain a tungstic acid solution. Take 20 μL of tungstic acid solution and add it dropwise on the surface of the FTO conductive glass obtained in step 1). The machine spin-coated evenly at a speed of 2000rpm for 10s, placed the FTO conductive glass in a muffle furnace, raised the temperature to 500°C at a speed of 5°C / min, and kept i...

Embodiment 2

[0037] A CuBi 2 o 4 / WO 3 The preparation method of composite film material composite fiber, it specifically comprises the following steps:

[0038] 1) Pretreatment of FTO conductive glass: Soak 1×2cm FTO conductive glass in ethanol and deionized water in turn, place it in a 400W ultrasonic cleaner for 30 minutes, remove the FTO conductive glass, dry it with nitrogen, and place it in 150W After 30 minutes of irradiation under a long-arc mercury lamp, weigh and record the mass of FTO glass as m 0 ';

[0039] 2) WO 3 Seed layer preparation: Weigh 3.0 g of tungstic acid into 75 mL of hydrogen peroxide, heat to 75°C and reflux and stir for 3.0 hours to obtain a tungstic acid solution. Take 20 μL of tungstic acid solution and add it dropwise on the surface of the FTO conductive glass obtained in step 1). The machine spin-coated evenly at a speed of 2000rpm for 15s, placed the FTO conductive glass in a muffle furnace, raised the temperature to 500°C at a speed of 5°C / min, and k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com