Bismuthate glasls and preparing method thereof

A bismuth salt glass and glass technology, applied in the field of bismuth salt glass and its preparation, can solve the problems of poor glass stability and processing difficulties, and achieve the effects of high transition temperature, high stability, and good infrared transmission ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

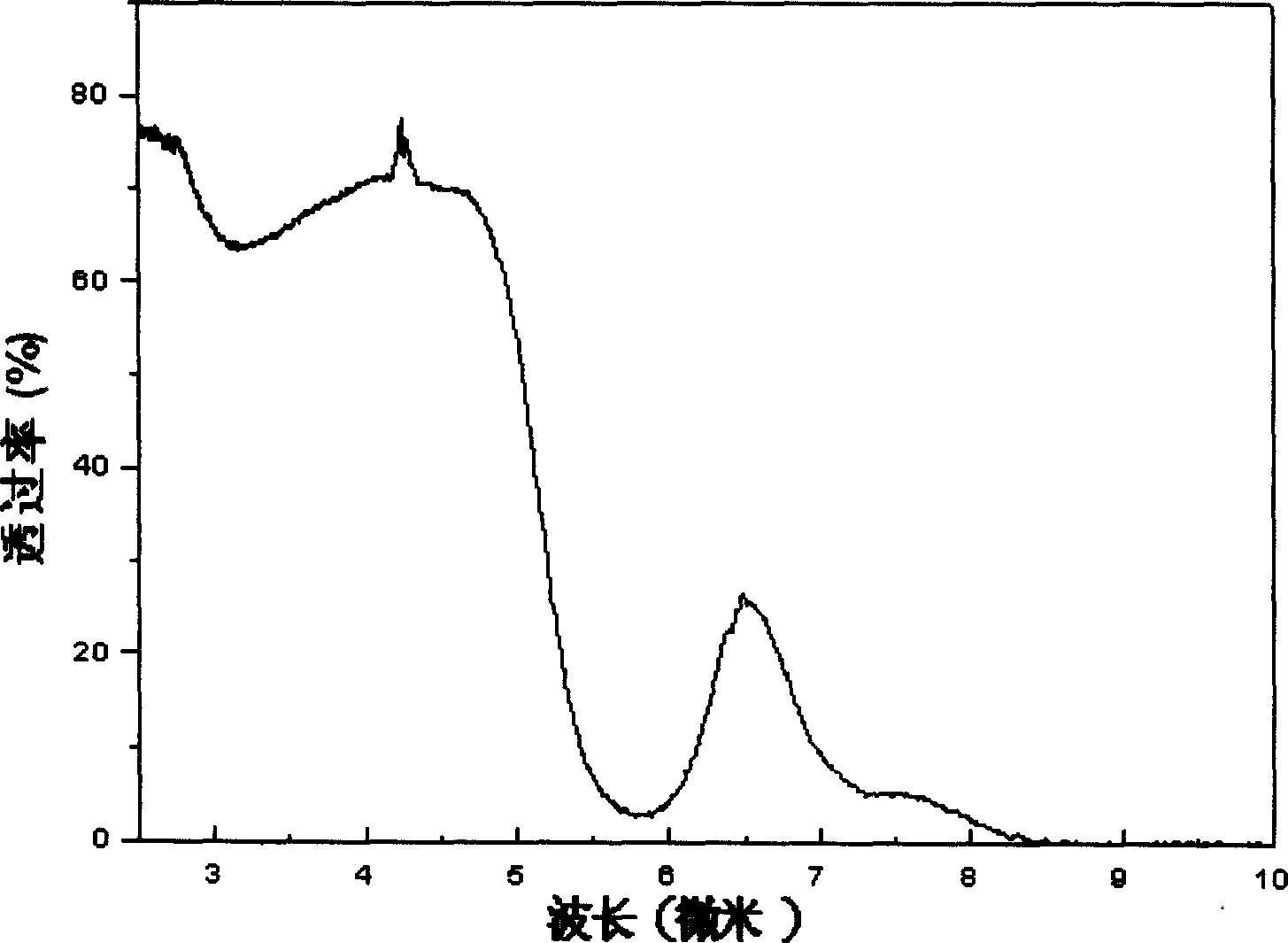

Image

Examples

Embodiment 1

[0034] Composition as in Table 1 1 # Shown, specific preparation method comprises the following steps:

[0035] ①: Calculate the weight percent of the glass according to the mole percent (mol%) of the glass composition, then weigh the raw materials and mix them uniformly;

[0036] ②: Put the mixture into a platinum crucible and melt it in a silicon carbon rod electric furnace at 1000 ° C. The length of melting time is determined according to the amount of raw materials;

[0037] ③: After the glass is melted, the temperature is lowered to 950°C, and high-purity oxygen is introduced to remove water. The aeration time depends on the amount of raw materials;

[0038] ④: Stop the oxygen flow, raise the temperature of the molten glass to 1000°C for clarification and homogenization, the time also depends on the amount of raw materials, and then pour the molten glass into the preheated mold;

[0039] ⑤: Quickly put the glass into the muffle furnace whose temperature has been raised ...

Embodiment 2

[0044] Composition as in Table 1 2 # Shown, specific preparation method comprises the following steps:

[0045] ①: Calculate the weight percent of the glass according to the mole percent (mol%) of the glass composition, then weigh the raw materials and mix them uniformly;

[0046] ②: Put the mixture into a platinum crucible and melt it in a silicon carbon rod electric furnace at 1000 ° C. The length of melting time is determined according to the amount of raw materials;

[0047] ③: After the glass is melted, the temperature is lowered to 950°C, and high-purity oxygen is introduced to remove water. The aeration time depends on the amount of raw materials;

[0048] ④: Stop the oxygen flow, raise the temperature of the molten glass to 1000°C for clarification and homogenization, the time also depends on the amount of raw materials, and then pour the molten glass into the preheated mold;

[0049] ⑤: Quickly put the glass into the muffle furnace whose temperature has been raised ...

Embodiment 3

[0054] Composition as in Table 1 3 # Shown, specific preparation method comprises the following steps:

[0055] ①: Calculate the weight percent of the glass according to the mole percent (mol%) of the glass composition, then weigh the raw materials and mix them uniformly;

[0056] ②: Put the mixture into a platinum crucible and melt it in a silicon carbon rod electric furnace at 1000 ° C. The length of melting time is determined according to the amount of raw materials;

[0057] ③: After the glass is melted, the temperature is lowered to 950°C, and high-purity oxygen is introduced to remove water. The aeration time depends on the amount of raw materials;

[0058] ④: Stop the oxygen flow, raise the temperature of the molten glass to 1000°C for clarification and homogenization, the time also depends on the amount of raw materials, and then pour the molten glass into the preheated mold;

[0059] ⑤: Quickly put the glass into the muffle furnace that has been heated to 398°C. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com