Method for deep purifying organic toxicant and waste water by photocatalysis-oxidation and preparation method for used photocatalysis material

A photocatalytic material, deep purification technology, applied in chemical instruments and methods, oxidized water/sewage treatment, energy wastewater treatment, etc., can solve the problems of incomplete mineralization, long treatment time, low degradation rate, etc., and achieve good visible light The effect of absorption performance, easy operation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A photocatalysis-oxidation method for deep purification of organic poison wastewater, using core-shell Cu 2 O-TiO 2 The combined technology of photocatalytic materials and photooxidant bismuthate to purify organic wastewater is carried out in the order of photocatalysis and oxidation, and Cu is used first 2 O-TiO 2 The photocatalytic material undergoes initial degradation, and then the photooxidant bismuthate is used for deep mineralization purification.

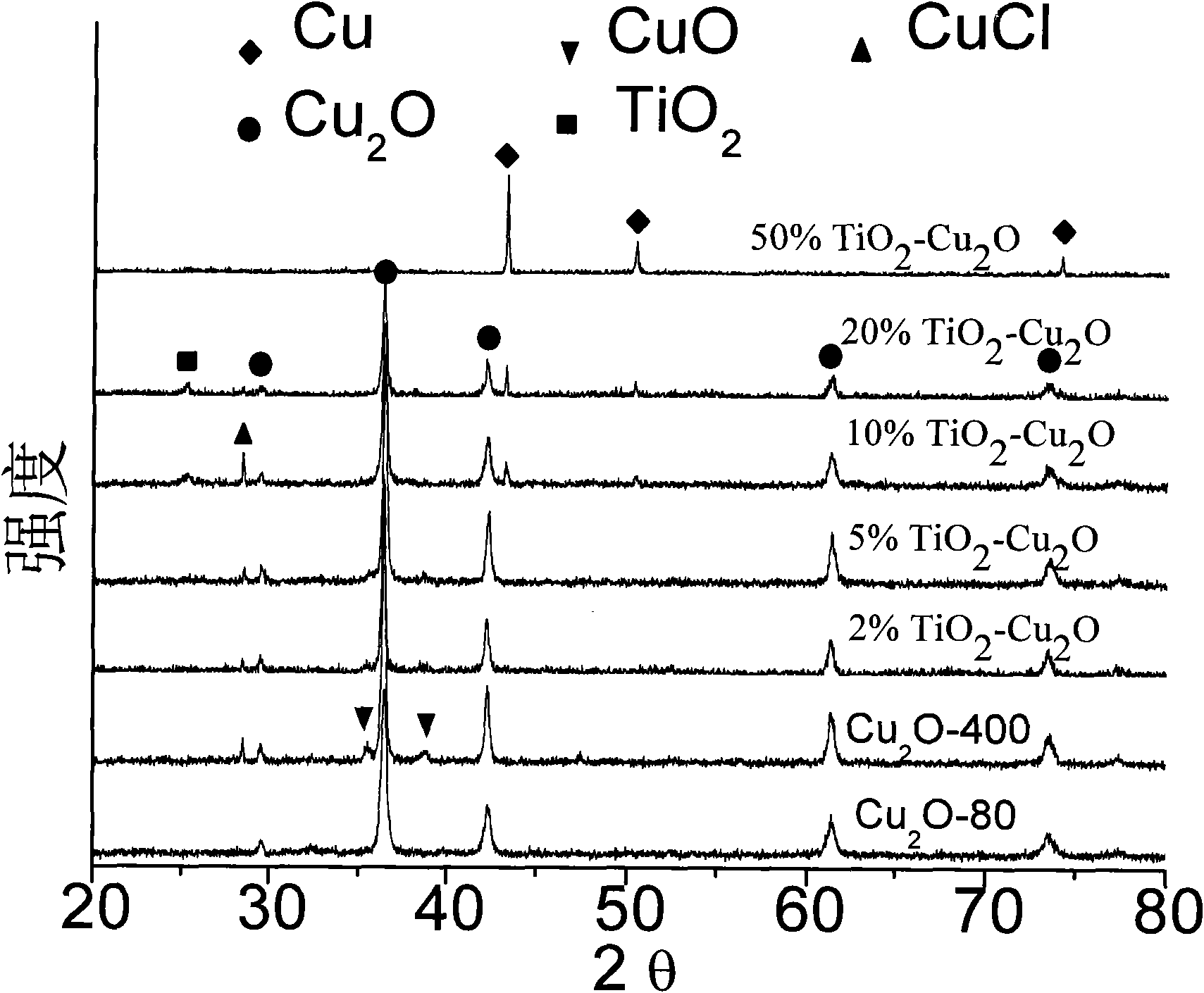

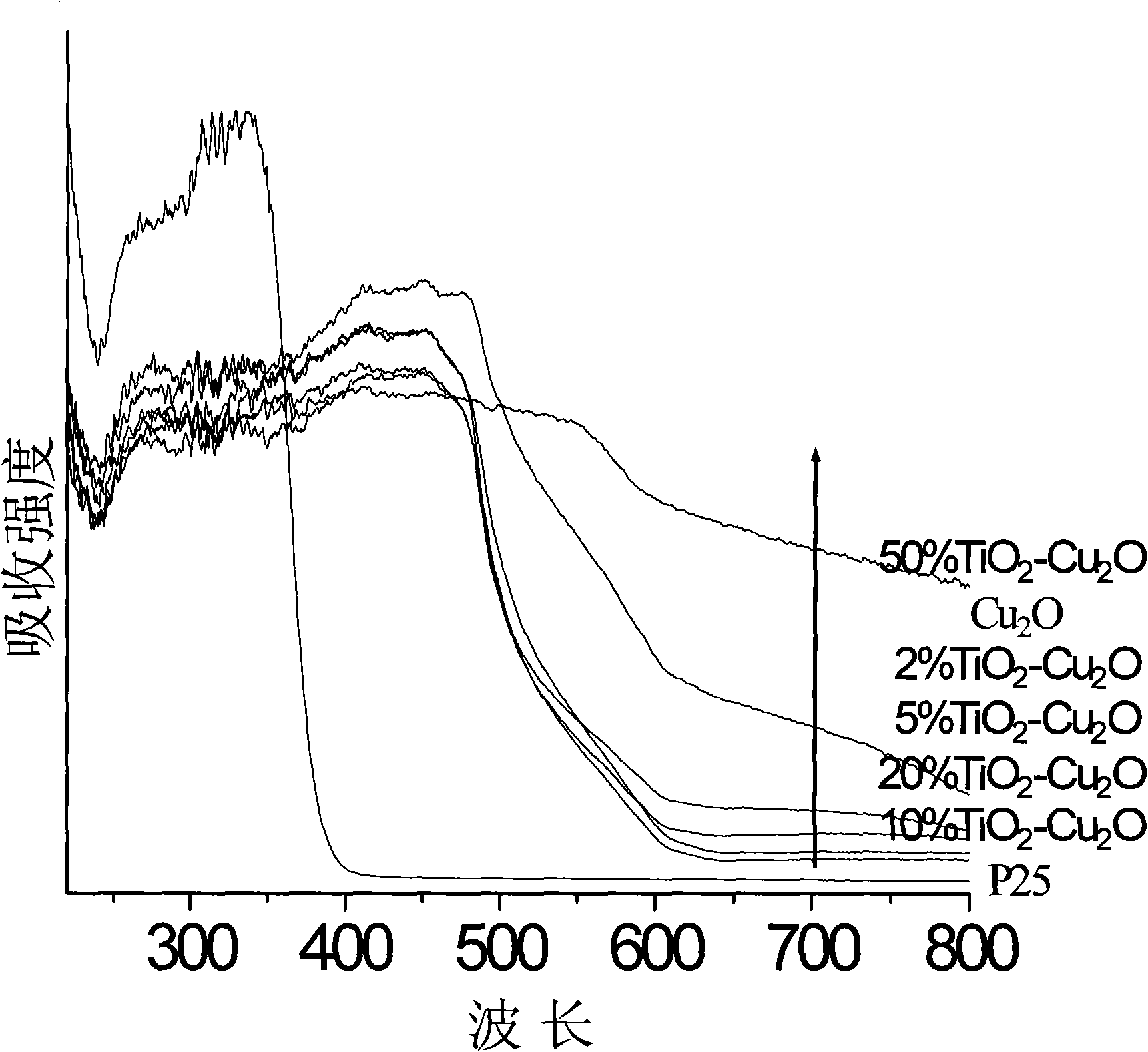

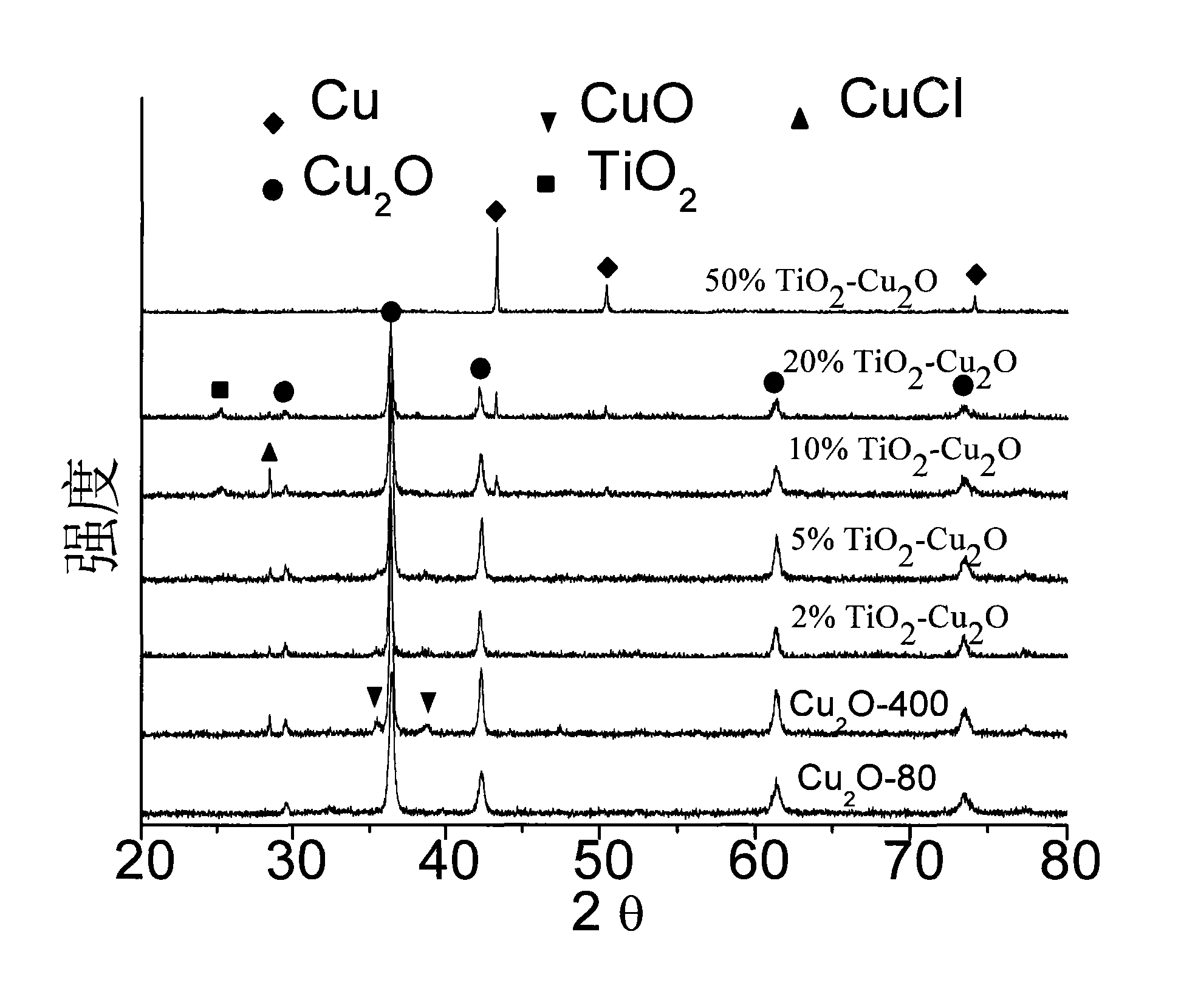

[0028] Cu used 2 O-TiO 2 The preparation of the core-shell photocatalytic material is as follows:

[0029] 0.3g Cu at room temperature 2 O was added to 100 ml of ethanol solution and sonicated for 10 minutes to form a uniformly dispersed suspension. Add 0.029 g of butyl titanate solution dropwise to the resulting solution, sonicate for 10 minutes, and then add dropwise 20 ml of anhydrous ethanol-water mixed solution (anhydrous ethanol: water = 200:1), after stirring for 24 hours in a water bath at 40 degrees Celsius, Filte...

Embodiment 2

[0031] A photocatalysis-oxidation method for deep purification of organic poison wastewater, using core-shell Cu 2 O-TiO 2 The combined technology of photocatalytic materials and photooxidant bismuthate to purify organic wastewater is carried out in the order of photocatalysis and oxidation, and Cu is used first 2 O-TiO 2 The photocatalytic material undergoes initial degradation, and then the photooxidant bismuthate is used for deep mineralization purification.

[0032] Cu used 2 O-TiO 2 The preparation of the core-shell photocatalytic material is as follows:

[0033] 0.3g Cu at room temperature 2 O was added to 100 ml of ethanol solution and sonicated for 10 minutes to form a uniformly dispersed suspension. Add 0.073 g of butyl titanate solution dropwise to the resulting solution, sonicate for 10 minutes, and then add dropwise 20 ml of anhydrous ethanol-water mixed solution (anhydrous ethanol: water = 200:1), and after stirring for 24 hours in a water bath at 40 degrees Celsius, F...

Embodiment 3

[0035] A photocatalysis-oxidation method for deep purification of organic poison wastewater, using core-shell Cu 2 O-TiO 2 The combined technology of photocatalytic materials and photooxidant bismuthate to purify organic wastewater is carried out in the order of photocatalysis and oxidation, and Cu is used first 2 O-TiO 2 The photocatalytic material undergoes initial degradation, and then the photooxidant bismuthate is used for deep mineralization purification.

[0036] Cu used 2 O-TiO 2 The preparation of the core-shell photocatalytic material is as follows:

[0037] 0.3g Cu at room temperature 2 O was added to 100 ml of ethanol solution and sonicated for 10 minutes to form a uniformly dispersed suspension. 0.357 g of butyl titanate solution was added dropwise to the resulting solution, sonicated for 10 minutes, and then 20 ml of anhydrous ethanol-water mixed solution (anhydrous ethanol: water = 200:1) was added dropwise, after stirring for 24 hours in a water bath at 40 degrees Ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com