Preparation method of porous dialkyl dithiocarbamate bismuth visible light catalyst

A technology of dialkyl dithiocarbamic acid and dialkyldithioamino group, which is applied in the field of preparation of porous dialkyldithiocarbamate bismuth visible light catalyst, can solve the problem of fast synthesis reaction rate, physical and chemical properties Difficult to study, hard to shape and other problems, to achieve uniform shape and size, excellent photocatalytic pollutant degradation and water splitting hydrogen production activity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

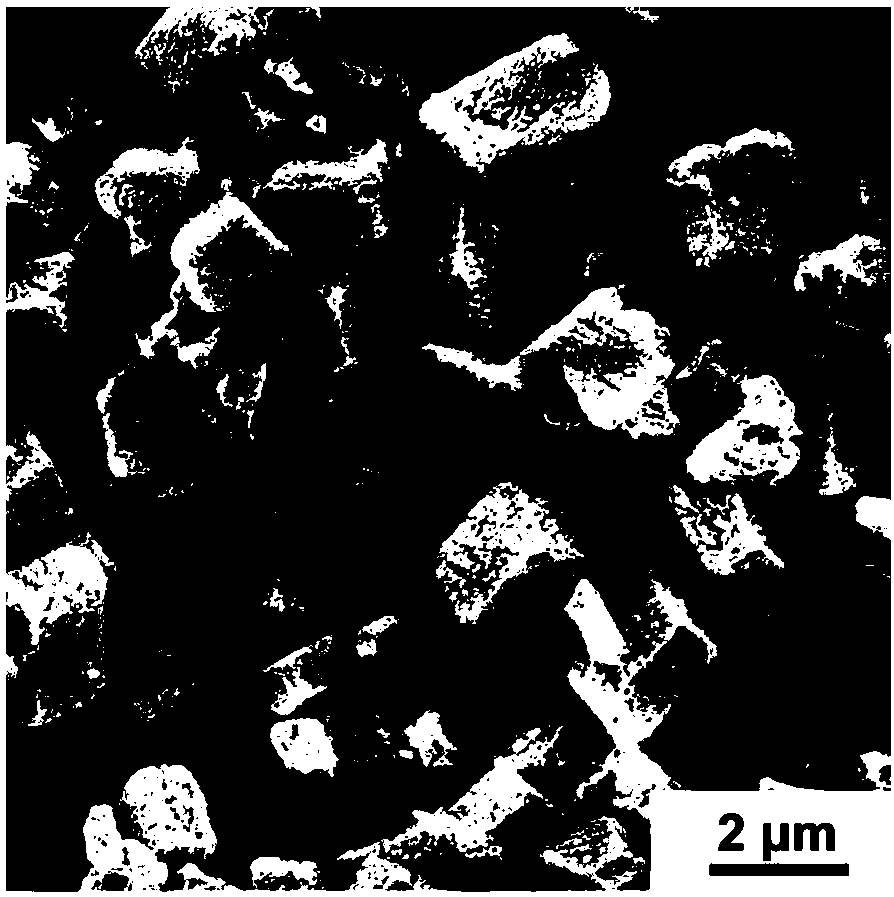

[0034]The preparation method of porous bismuth diethyldithiocarbamate is: at room temperature, 1mmol bismuth acetate and 3mmol sodium diethyldithiocarbamate trihydrate are respectively dissolved in 20mL edetate disodium aqueous solution (0.15 mol / L) and pure water, the sodium diethyldithiocarbamate aqueous solution is added dropwise in the bismuth acetate aqueous solution, gradually produces a yellow precipitate, after the dropwise addition is completed, filter, add 40mL water, filter, wash and dry to obtain The yellow powder with a size of 2 μm is porous bismuth diethyldithiocarbamate particles.

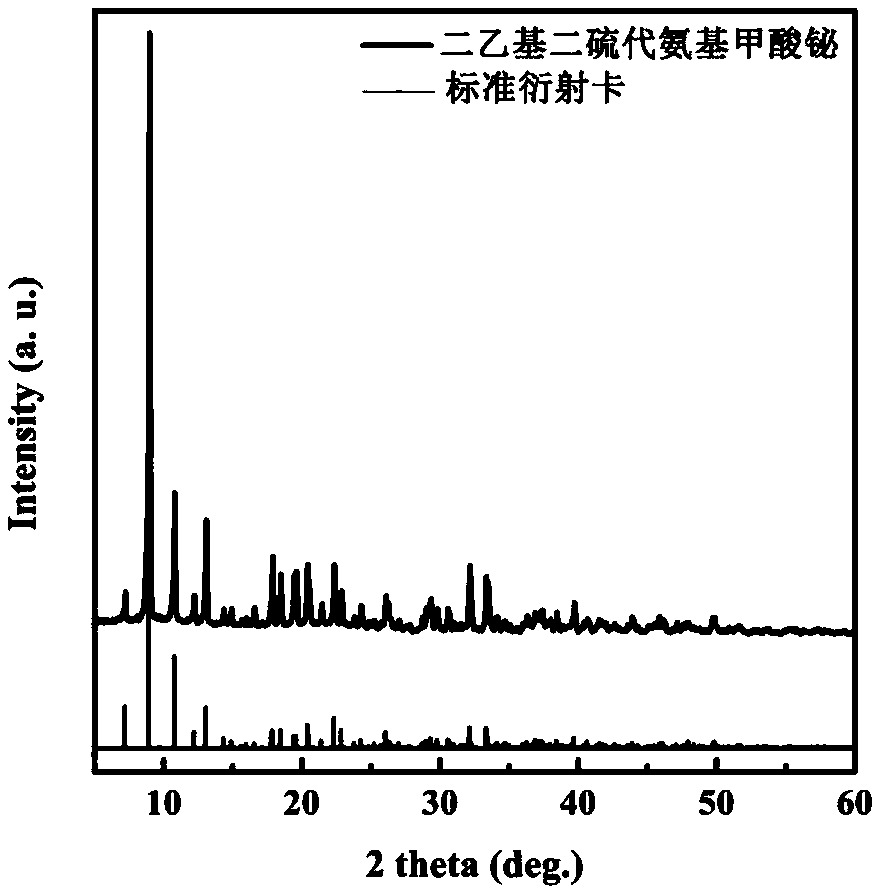

[0035] The prepared porous bismuth diethyldithiocarbamate particles are identified as monoclinic phase through powder X-ray diffraction, with high crystallinity (see figure 1 ); the product was observed with a scanning electron microscope to be a square with a nanoporous structure on the surface, and the size was 2 μm (see figure 2 ); detected with a UV-visible spectrophotometer, ...

Embodiment 2

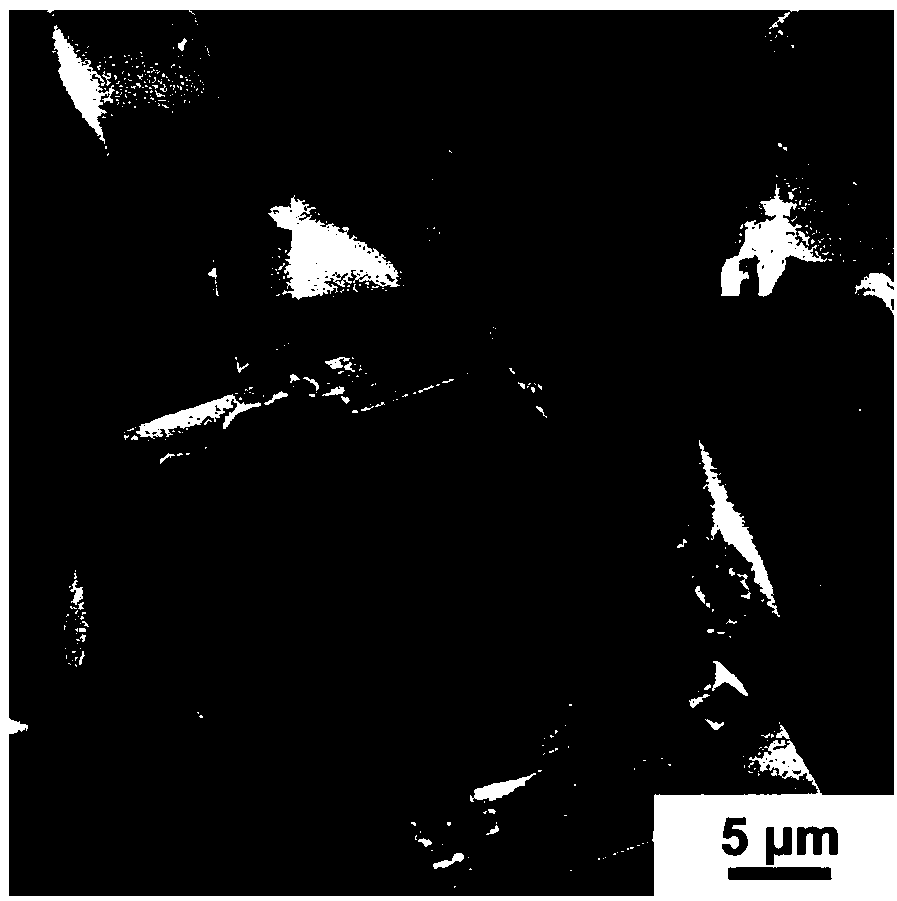

[0037] The preparation method of porous bismuth diethyldithiocarbamate is: at 60 DEG C, 1mmol bismuth neododecanoate and 3mmol ammonium diethyldithiocarbamate are respectively dissolved in 20mL ethanol (with hydrochloric acid to adjust the pH to be less than 2 ) and pure ethanol, the diethyldithiocarbamate ammonium ethanol solution is added dropwise in the bismuth neododecanoate ethanol solution, gradually produces a yellow precipitate, after the dropwise addition, filter, add 40mL water, filter, wash and Dried to obtain a yellow powder with a size of 20 μm (see image 3 ), which are porous bismuth diethyldithiocarbamate particles.

Embodiment 3

[0039] The preparation method of porous bismuth diethyldithiocarbamate is: under 0 ℃ ice bath, 1mmol bismuth acetate and 3mmol sodium diethyldithiocarbamate trihydrate are respectively dissolved in 20mL formamide (adjust pH with hydrochloric acid Less than 2) and pure formamide, add sodium diethyldithiocarbamate formamide solution dropwise to bismuth acetate formamide solution, gradually produce a yellow precipitate, after the dropwise addition, filter, add 40mL of water, filter and wash and drying to obtain a yellow powder with a size of 100 μm, namely porous bismuth diethyldithiocarbamate particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com