Method for preparing metal-free high molecular polymer photocatalysis material

A technology of photocatalytic materials and polymers, which is applied in the field of preparation of polymer photocatalytic materials, can solve the problems of less types of materials and non-environmental protection in the preparation process, and achieve the effect of environmental protection in the preparation process, less steps and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of HPI photocatalytic materials:

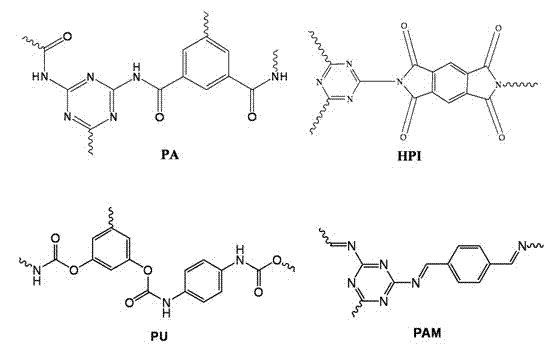

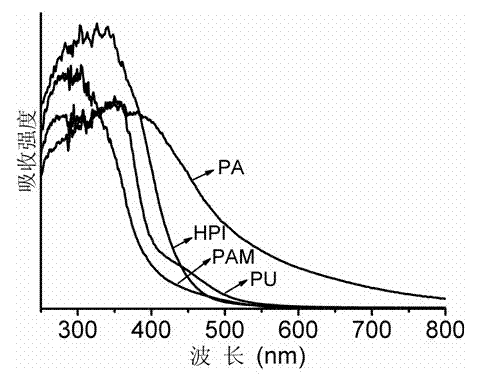

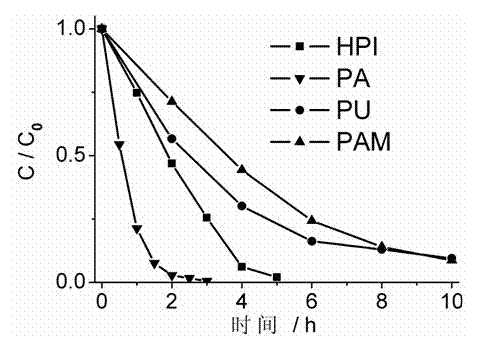

[0032] Grind 1.26g (0.01 mol) melamine and 2.18g (0.01 mol) pyromellitic anhydride white powder evenly, place in a semi-closed stone boat, raise the temperature to 325°C at a rate of 7°C / min, keep the temperature for 4h, and cool to After room temperature, a yellow lump was obtained, which was ground into powder, washed with hot water, filtered and dried to obtain HPI photocatalytic material, and the molecular structure characteristic diagram is as follows: figure 1 shown. The specific surface area determined by nitrogen adsorption / desorption isotherm is 5.07m 2 / g, the absorption range measured by UV-visible absorption spectrum is 200-550nm, and the UV-Vis spectrum is as follows figure 2 shown. Put 0.2 g of HPI photocatalytic material in 100 ml of organic wastewater containing 4 ppm of Rhodamine B, stir for 60 min to reach adsorption equilibrium, turn on the xenon lamp light source with a 420 nm filter, react with visi...

Embodiment 2

[0034] Preparation of PA photocatalytic materials:

[0035] Grind 1.26g (0.01 mol) melamine and 2.10g (0.01 mol) white powder of tribenzenetricarboxylic acid evenly, place in a semi-closed stone boat, raise the temperature to 360°C at a rate of 7°C / min, keep the temperature for 4h, and cool to After room temperature, a deep yellow block was obtained, which was ground into powder, washed with hot water, filtered and dried to obtain a PA photocatalytic material, and the molecular structure characteristic diagram is as follows: figure 1 shown. The specific surface area determined by the nitrogen adsorption / desorption isotherm is 4.06m 2 / g, the absorption range measured by UV-visible absorption spectrum is 200-800nm, and the UV-Vis spectrum is as follows figure 2 shown. Put 0.2g of PA photocatalytic material in 100ml of organic wastewater containing Rhodamine B 4ppm, stir for 60min to reach adsorption equilibrium, turn on the xenon lamp light source with a 420nm filter, react...

Embodiment 3

[0037] Preparation of PU photocatalytic material:

[0038] Grind 1.26g (0.01 mol) of pyroglucinol and 1.60g (0.01 mol) of p-phenylene diisocyanate white powder evenly, place them in a semi-closed stone boat, raise the temperature to 150°C at a rate of 7°C / min, and keep the temperature for 4h. After cooling to room temperature, a yellow lump was obtained, which was ground into a powder, washed with hot water, filtered and dried to obtain a PU photocatalytic material, and the molecular structure characteristic diagram is as follows: figure 1 shown. The specific surface area determined by the nitrogen adsorption / desorption isotherm is 1.82m 2 / g, the absorption range measured by UV-visible absorption spectrum is 200-600nm, and the UV-Vis spectrum is as follows figure 2 shown. Put 0.2g PU photocatalytic material in 100ml organic wastewater containing 4ppm rhodamine B, stir for 60min to reach adsorption equilibrium, turn on the xenon lamp light source with 420nm filter, and rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com