Preparation method of graphite type carbon nitride nanotubes

A graphitic carbon nitride and nanotube technology, applied in nanotechnology, nitrogen and non-metallic compounds, etc., can solve the problems of high production cost, small output, complex process, etc., and achieve low price, reduce specific surface energy, Beneficial for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the first step, a certain amount of melamine powder is added to the ceramic crucible, and the ceramic crucible is placed on a vibrator for vibration treatment, so that the melamine powder is changed from random accumulation to an orderly arrangement of medium close accumulation. The medium close packing form mentioned in the present invention is an intermediate situation between natural disordered packing and compaction by means of external force. Moderately close-packed form.

[0043] In the second step, the ceramic crucible is covered to form a semi-closed environment, and then placed in a muffle furnace controlled by temperature programming, and the temperature is rapidly raised from room temperature to 500 °C at a heating rate of 10 °C / min, and then Keep at this temperature for 2h.

[0044] In the third step, the temperature of the muffle furnace is raised to 520° C. / min at a rate of 2° C. / min, and kept at this temperature for 2 hours for further deamination.

...

Embodiment 2

[0051] In the first step, a certain amount of melamine powder is added to the ceramic ark, and the ceramic ark is placed on a vibrator for vibration treatment, so that the melamine powder is changed from random accumulation to an orderly arrangement of medium and close accumulation.

[0052] In the second step, cover the ceramic ark to form a semi-enclosed environment, and then put it into a muffle furnace controlled by temperature programming, rapidly increase the temperature from room temperature to 490 °C at a heating rate of 5 °C / min, and Keep at this temperature for 3h.

[0053] In the third step, the temperature of the muffle furnace is raised to 550° C. / min at a rate of 3° C. / min, and kept at this temperature for 1 hour for further deamination.

[0054] In the fourth step, after cooling to room temperature, the obtained product is ground in an agate mortar to obtain graphite-type carbon nitride nanotubes.

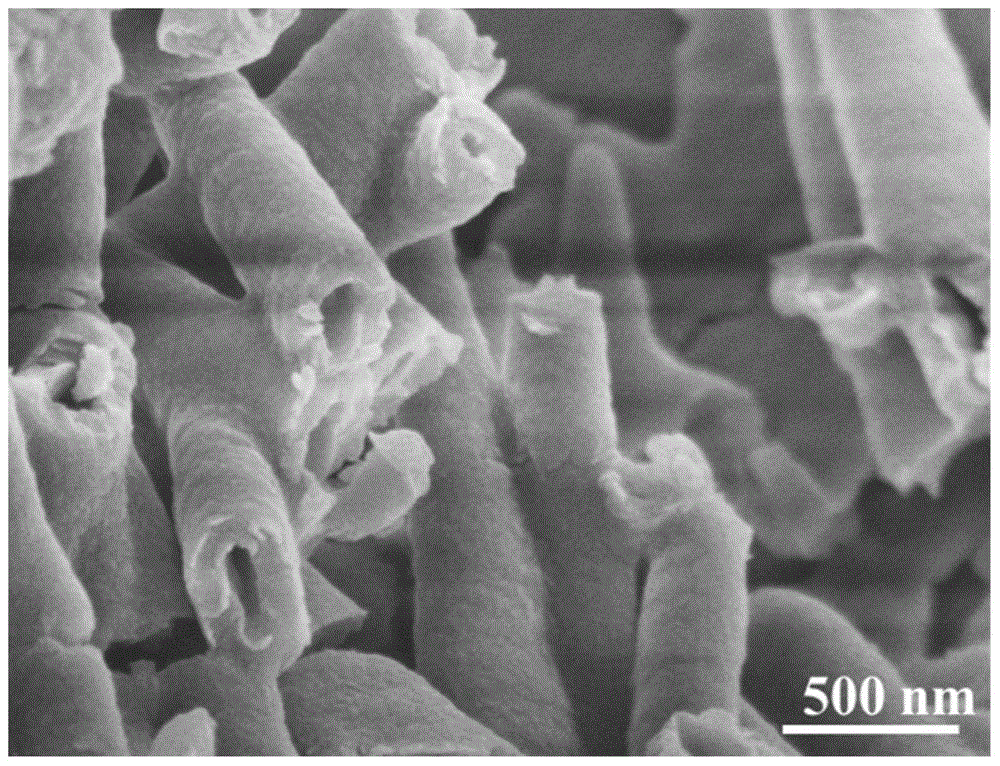

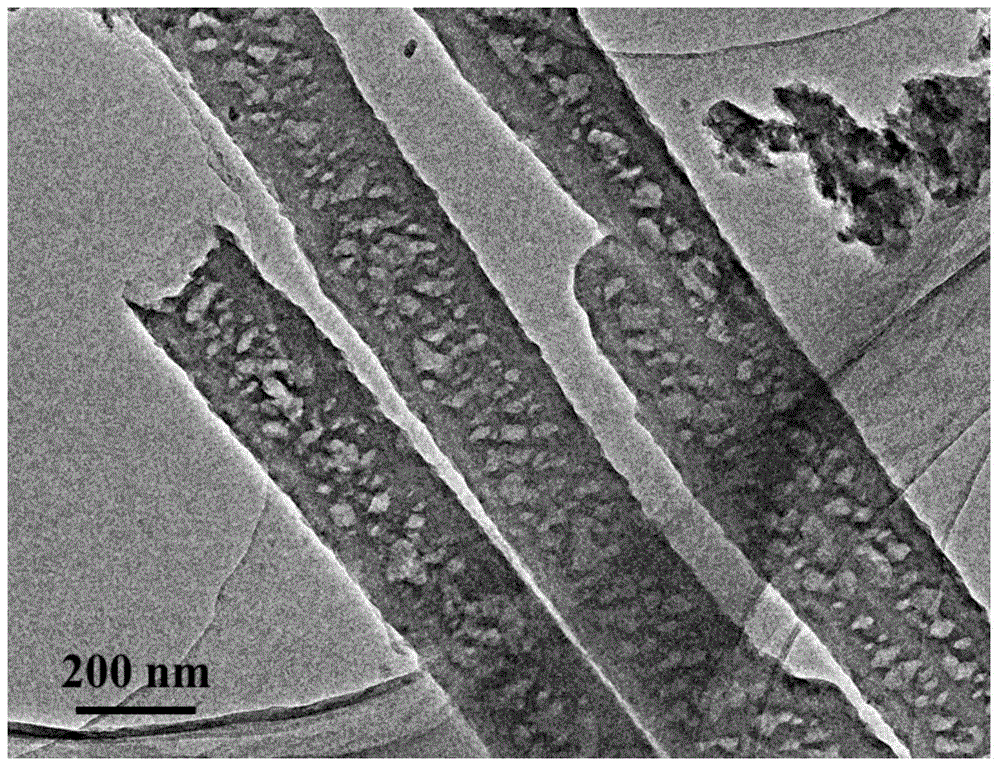

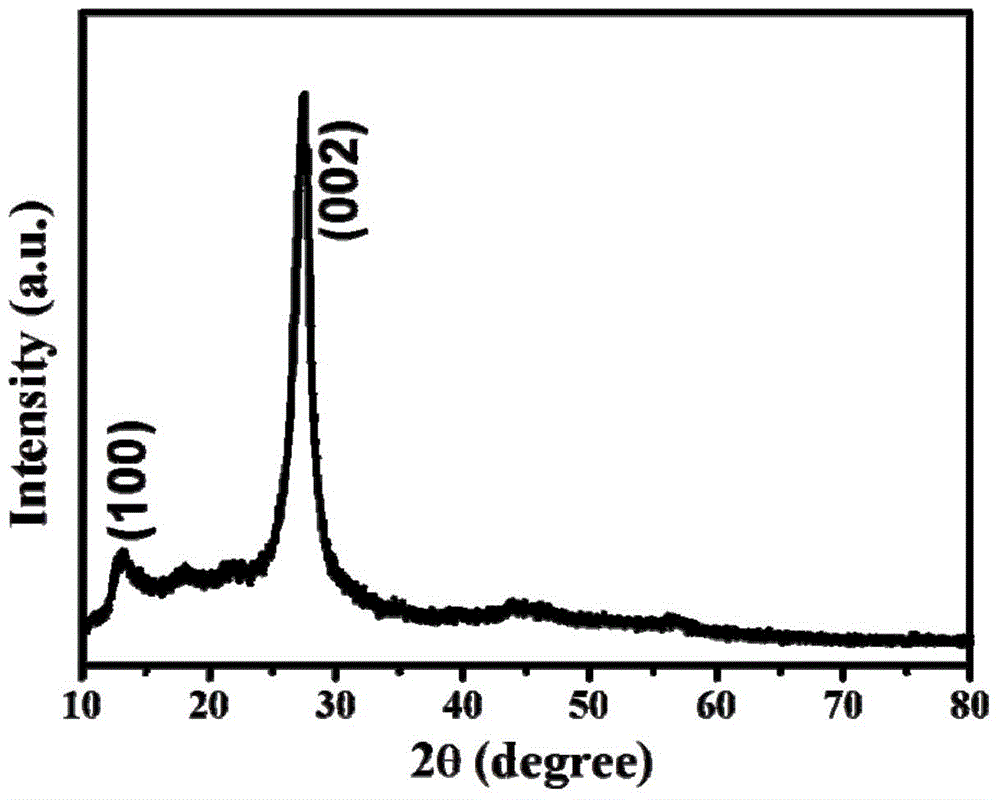

[0055] By characterizing the graphite-type carbon nitride nano...

Embodiment 3

[0058] In the first step, a certain amount of melamine powder is added to the ceramic crucible, and the ceramic crucible is placed on a vibrator for vibration treatment, so that the melamine powder is changed from a random stacked form to an orderly arranged medium-close packed form.

[0059] In the second step, the ceramic crucible is covered to form a semi-closed environment, and then placed in a muffle furnace controlled by temperature programming, and the temperature is rapidly raised from room temperature to 510 °C at a heating rate of 5 °C / min, and then Keep at this temperature for 1h.

[0060] In the third step, the temperature of the muffle furnace is raised to 530° C. / min at a rate of 1° C. / min, and kept at this temperature for 3 hours for further deamination.

[0061] In the fourth step, after cooling to room temperature, the obtained product is ground in an agate mortar to obtain graphite-type carbon nitride nanotubes.

[0062] By characterizing the graphite-type c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com