Conduction through a flexible substrate in an article

A technology of flexible substrates and products, applied in medical science, absorbent pads, etc., can solve difficult electrical and mechanical interconnection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

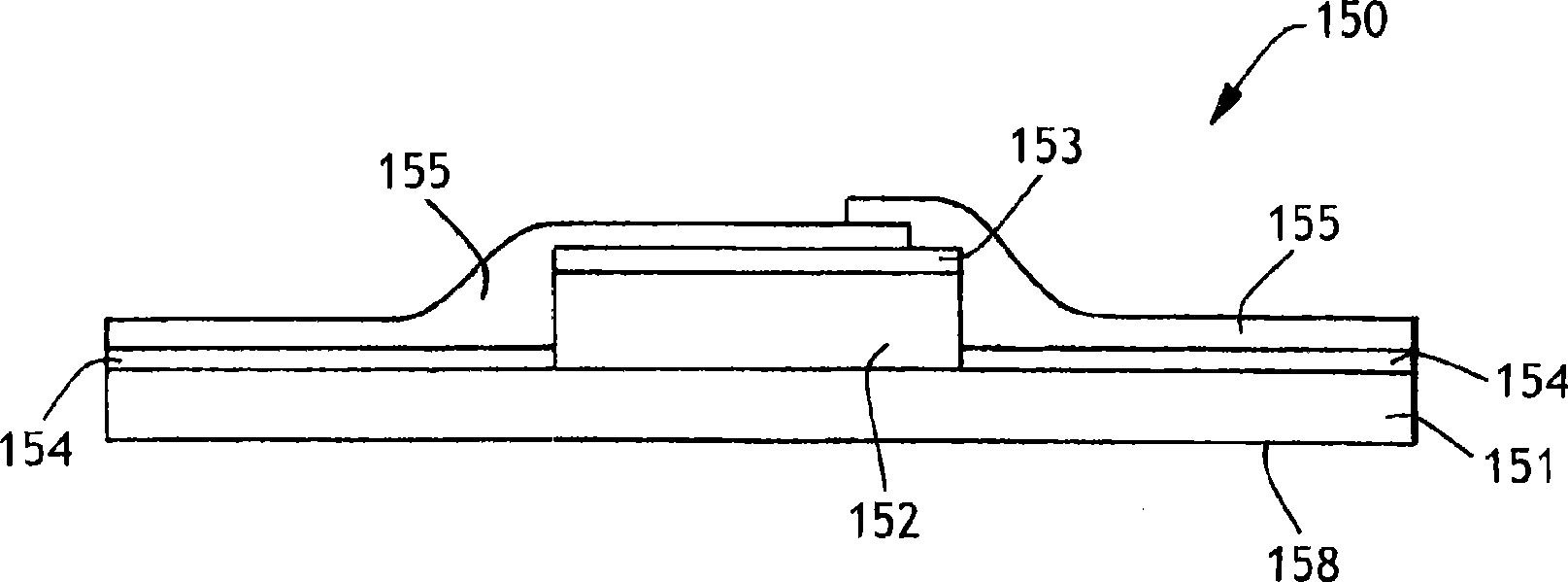

[0138] A first copper-based circuit path having a length of about 10 cm, a width of about 10 mm, and a thickness ranging from about 0.1 μm to about 0.4 μm is printed onto one side of the flexible substrate by inkjet printing. The substrate, which functions as the backsheet of the current HUGGIES PULL-UPS STEP 3 training pant, is approximately 0.75 mil (19 μm) thick with a flexibility in the range of approximately 0.0017 to 0.0021 gfcm2 / cm according to the KES Pure Bend test (supra described) measured. A hole measuring approximately 0.1 mm in diameter was formed in the substrate with a pin at the middle of the first circuit path length (approximately 5 cm from each end). The PERMATEX Quick Grid Rear Window Defogger Repair Kit (available from Permatex, Inc., a business with offices in Hartford, Connecticut, U.S.A.) was then applied to the opposite side of the substrate using the PERMATEX Quick Grid Rear Window Defogger Repair Kit. The second circuit path has a length of about 1...

Embodiment 2

[0141] A circuit made according to Example 1 was draped over a standard laboratory flask having a circular upper opening about 70 mm wide and about 200 mm high such that the substrate formed a hemisphere with the holes containing the conductive filler located in the hemisphere bottom and in the center of the flask. The substrate hemispheres were flooded with water and allowed to sit for 10 minutes. Water was then drained from the top of the membrane and the membrane was removed from the flask. The flask below the membrane was found to be completely dry. This example demonstrates that the invention preserves the fluid-tight properties of the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Softening point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com