Copper bismuthate film embedded with ligand-free quantum dots, and preparation method and application thereof

A quantum dot, ligand-free technology, applied in chemical instruments and methods, catalyst activation/preparation, electrodes, etc., can solve the problems of complex photoelectrode preparation process, low photocurrent density, and lack of doping strategies in thin films, and achieve improved The effect of carrier separation efficiency, simple preparation process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

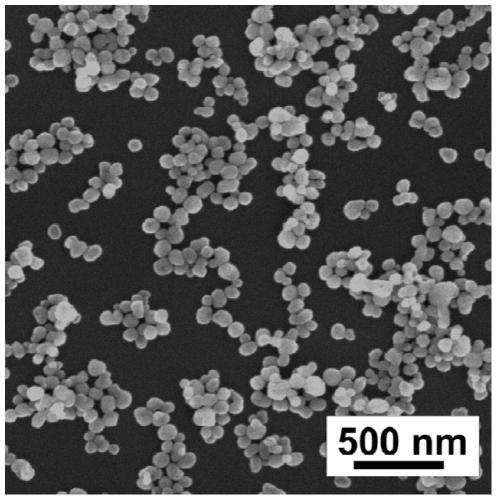

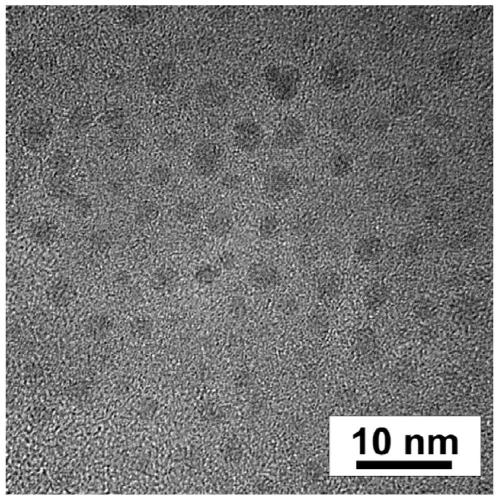

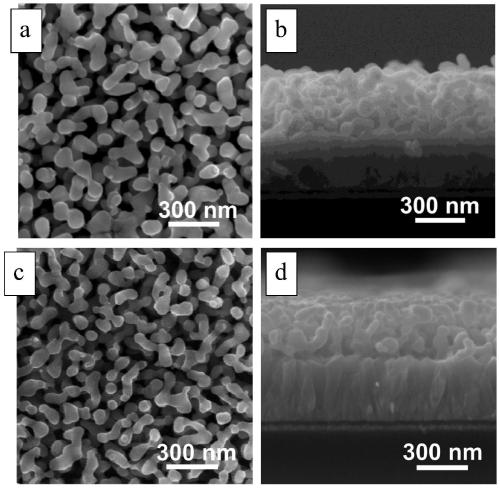

[0035] A mosaic BaTiO 3 Copper bismuthate film without ligand quantum dots, including nanoporous copper bismuthate film and BaTiO embedded in the bismuthate copper film 3 Ligand-free quantum dots, and BaTiO 3 Ligand-free quantum dots in mosaic BaTiO 3 The mass fraction in the copper bismuth oxide thin film without ligand quantum dots is 5.0%.

[0036] Concrete preparation method comprises the following steps:

[0037] S1, the Cu(NO 3 ) 2 ·3H 2 O and Bi(NO 3 ) 3 ·5H 2 O is dissolved in a solvent mixed with ethanol, ethylene glycol and acetic acid in equal volumes at a molar ratio of 1:2. After mixing evenly, add block copolymer F108 and mix evenly to obtain 0.1mol / ml CuBi 2 o 4 Precursor solution; Among them, CuBi 2 o 4 The concentration of block copolymer F108 in the precursor solution is 0.1 mg / ml; the addition of F108 can increase the viscosity of the solution on the one hand to facilitate film formation, and on the other hand, it can be used as a template to for...

Embodiment 2

[0043] A mosaic SrTiO 3 Copper bismuthate film without ligand quantum dots, including nanoporous copper bismuthate film and SrTiO embedded in the bismuthate copper film 3 Ligand-free quantum dots, and SrTiO 3 Ligand-free quantum dots in mosaic SrTiO 3 The mass fraction in the copper bismuth oxide thin film without ligand quantum dots is 0.1%.

[0044] Concrete preparation method comprises the following steps:

[0045] S1, the Cu(NO 3 ) 2 ·3H 2 O and Bi(NO 3 ) 3 ·5H 2 O is dissolved in a solvent mixed with ethanol, ethylene glycol and acetic acid in equal volumes at a molar ratio of 1:2. After mixing evenly, add block copolymer F108 and mix evenly to obtain 0.5mol / ml CuBi 2 o 4 Precursor solution; Among them, CuBi 2 o 4 The concentration of block copolymer F108 in the precursor solution is 0.1mg / ml;

[0046] S2, 1mgSrTiO 3 The particles are dispersed in 10ml of a solvent mixed with ethanol, ethylene glycol and acetic acid in equal volumes to obtain a mixed solutio...

Embodiment 3

[0051] A copper bismuthate film embedded with Au ligand-free quantum dots, comprising a nanoporous copper bismuthate film and Au ligand-free quantum dots embedded in the copper bismuthate film, and the Au ligand-free quantum dots are inlaid The mass fraction of Au ligand-free quantum dots in the copper bismuth oxide film is 3%.

[0052] Concrete preparation method comprises the following steps:

[0053] S1, the Cu(NO 3 ) 2 ·3H 2 O and Bi(NO 3 ) 3 ·5H 2 O is dissolved in a solvent mixed with ethanol, ethylene glycol and acetic acid in equal volumes at a molar ratio of 1:2. After mixing evenly, add block copolymer F108 and mix evenly to obtain 0.2mol / ml CuBi 2 o 4 Precursor solution; Among them, CuBi 2 o 4 The concentration of block copolymer F108 in the precursor solution is 0.1mg / ml;

[0054] S2, put the Au sheet in 10ml of a mixed solvent composed of ethanol, ethylene glycol, and acetic acid in equal volumes, and irradiate the mixed solvent containing the Au sheet u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com