Infrared transparent conductive film, and preparation method and application thereof

A transparent conductive film, infrared technology, used in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problems of image quality, poor performance of multi-layer films, no electromagnetic shielding, etc., and achieve good electrical conductivity. high infrared transmittance, simple preparation process, and high infrared transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

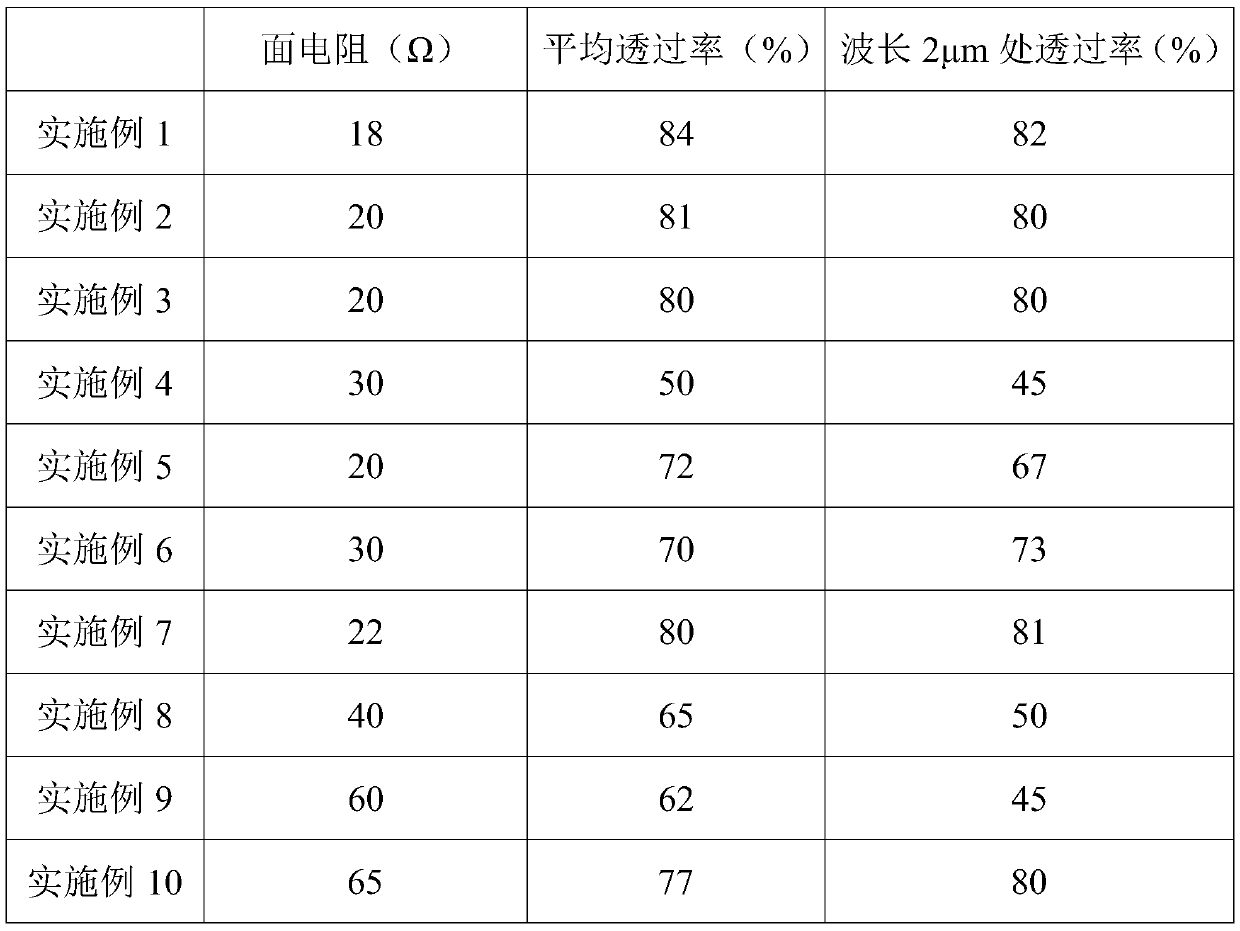

Embodiment 1

[0072] A kind of preparation method of infrared transparent conductive film comprises the steps:

[0073] (1) Vacuumize the system to a vacuum degree of 2.5×10 -4 Pa, then filled with oxygen to a vacuum of 2.4×10 -2 Pa, with the beam flow of yttrium oxide being 80mA, depositing yttrium oxide on quartz with a thickness of 1mm at 200°C at a rate of 0.4nm / s to obtain a seed layer with a thickness of 50nm;

[0074] (2) annealing the seed layer obtained in step (1) at 500° C. for 2 hours to obtain the annealed seed layer;

[0075] (3) With the beam current of indium oxide doped with cerium fluoride being 30mA, a conductive layer with a thickness of 150nm was deposited on the annealed seed layer at a speed of 0.2nm / s with indium oxide doped with cerium fluoride, The content of cerium fluoride in the conductive layer is 5 wt%, and then annealed at 300° C. for 1 hour to obtain an infrared transparent conductive film. The structure of the infrared transparent conductive film is as ...

Embodiment 2

[0077] The difference from Example 1 is that the deposition thickness of the seed layer in step (1) is 20 nm.

Embodiment 3

[0079] The difference from Example 1 is that the deposition thickness of the seed layer in step (1) is 300 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com