Window with infrared transparent conductive function

A technology of transparent conduction and transparent conduction layer, which is applied in the direction of equipment for manufacturing conduction/semiconduction layer, conduction layer on insulating carrier, circuit, etc. It can solve the problem that windows cannot take into account electromagnetic shielding and high infrared transmittance performance, etc. problems, achieve good infrared transmission and electromagnetic shielding performance, improve infrared transmittance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

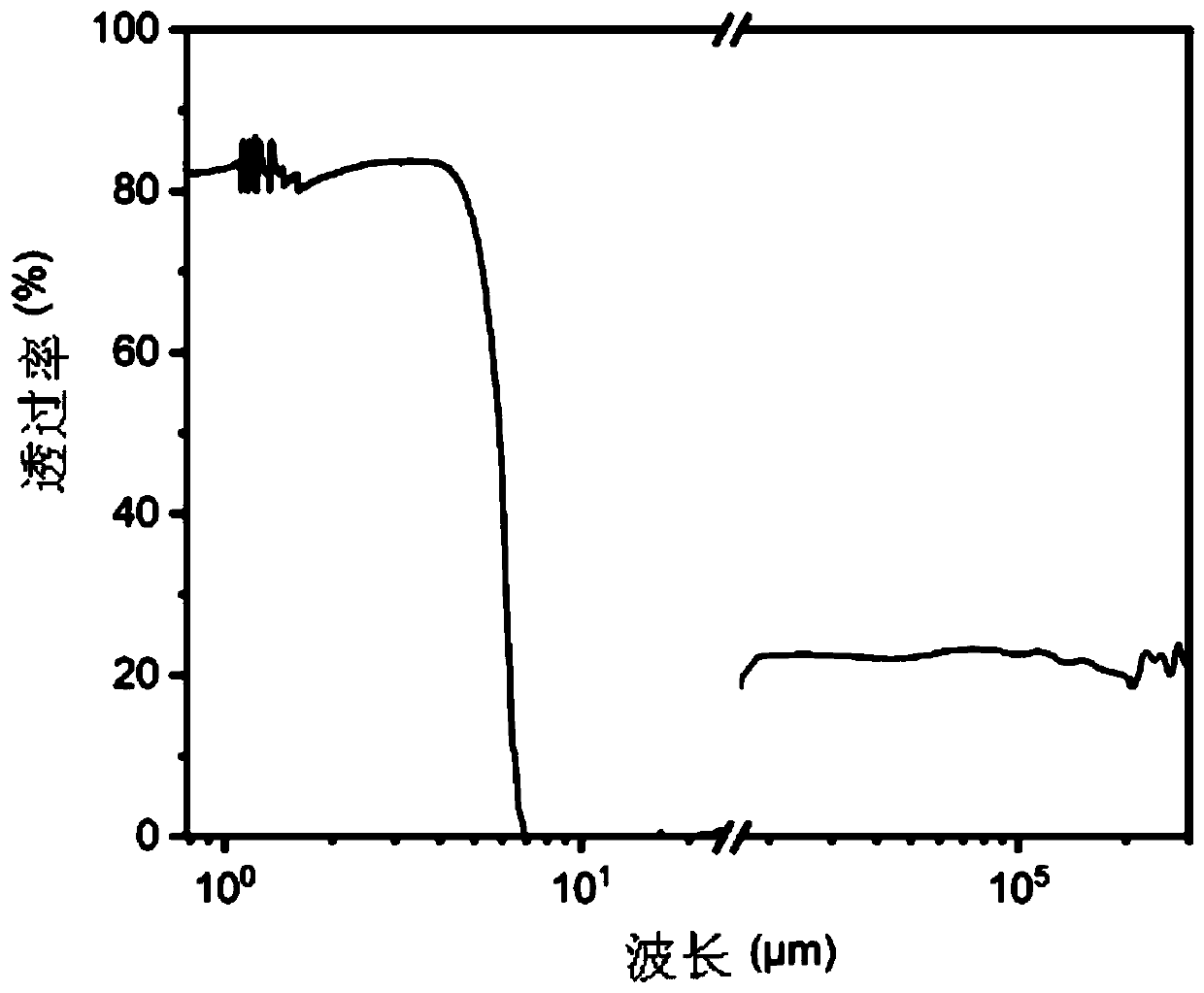

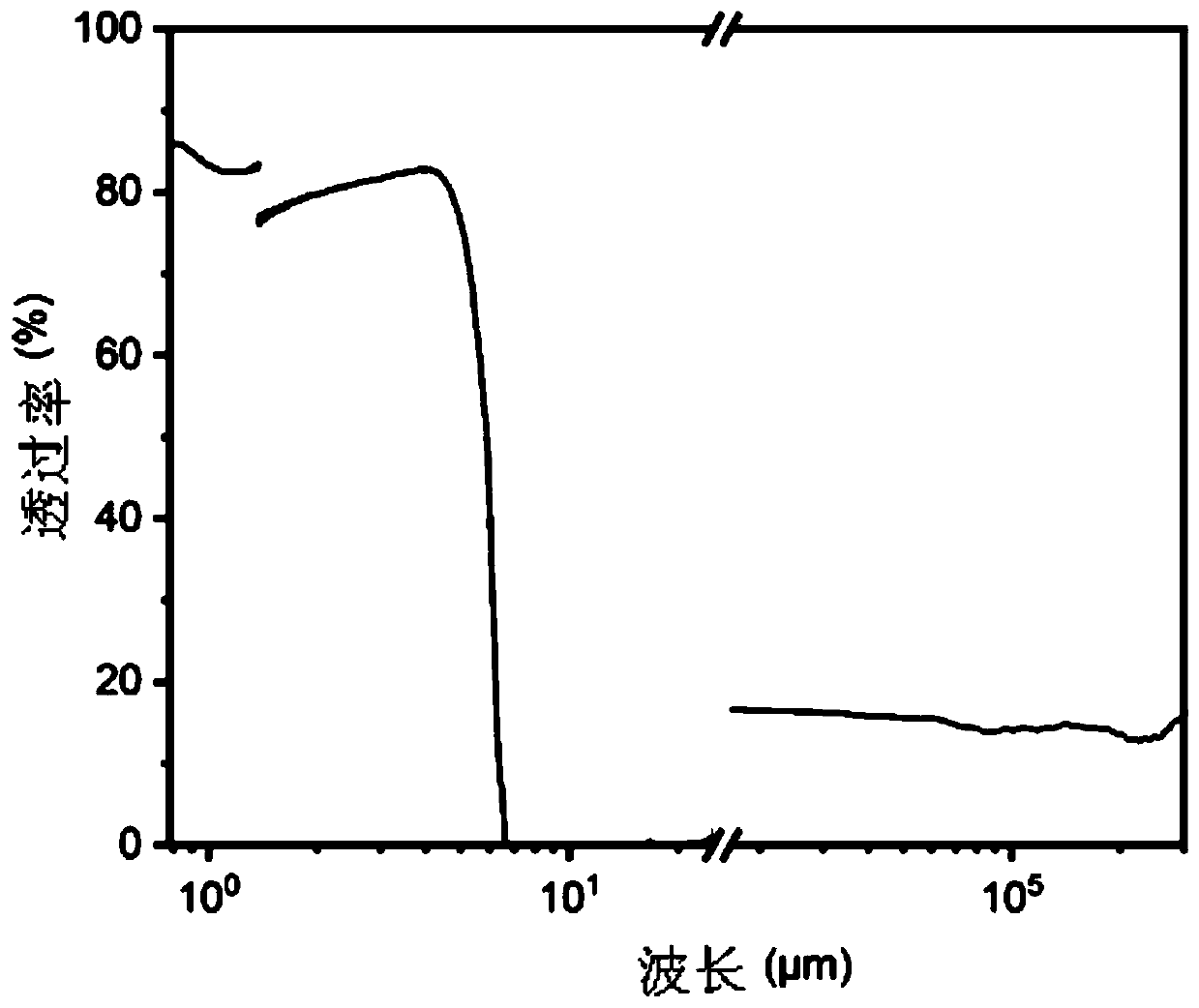

[0036] Embodiment 1: This embodiment is a window with an infrared transparent conductive function, which is specifically composed of a substrate, a transparent conductive layer and an infrared anti-reflection layer grown on the substrate in sequence;

[0037] The substrate is a sapphire substrate, the orientation is the (0001) crystal plane, the sapphire substrate is polished on both sides, and the thickness is 100 μm to 30000 μm;

[0038] The transparent conductive layer is made of tin-doped indium oxide (ITO), aluminum-doped zinc oxide (AZO), gallium-doped zinc oxide (GZO), fluorine-doped tin oxide (FTO), tin oxide (SnOx), Yttrium oxide doped ruthenium (YRO), nitrogen doped indium oxide (InNO) and indium oxide (In 2 o 3 ) in one or more laminates; the total thickness of the transparent conductive layer is 0.1 μm to 100 μm, and the average electron concentration is not higher than 1×10 20 cm -3 ;

[0039] The infrared antireflection layer is magnesium fluoride (MgF 2 ), ...

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment is different from Embodiment 1 in that: the thickness of the substrate is 1 mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the total thickness of the transparent conductive layer is 0.89 μm, and the average electron concentration is 9.76×10 18 cm -3 . Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com