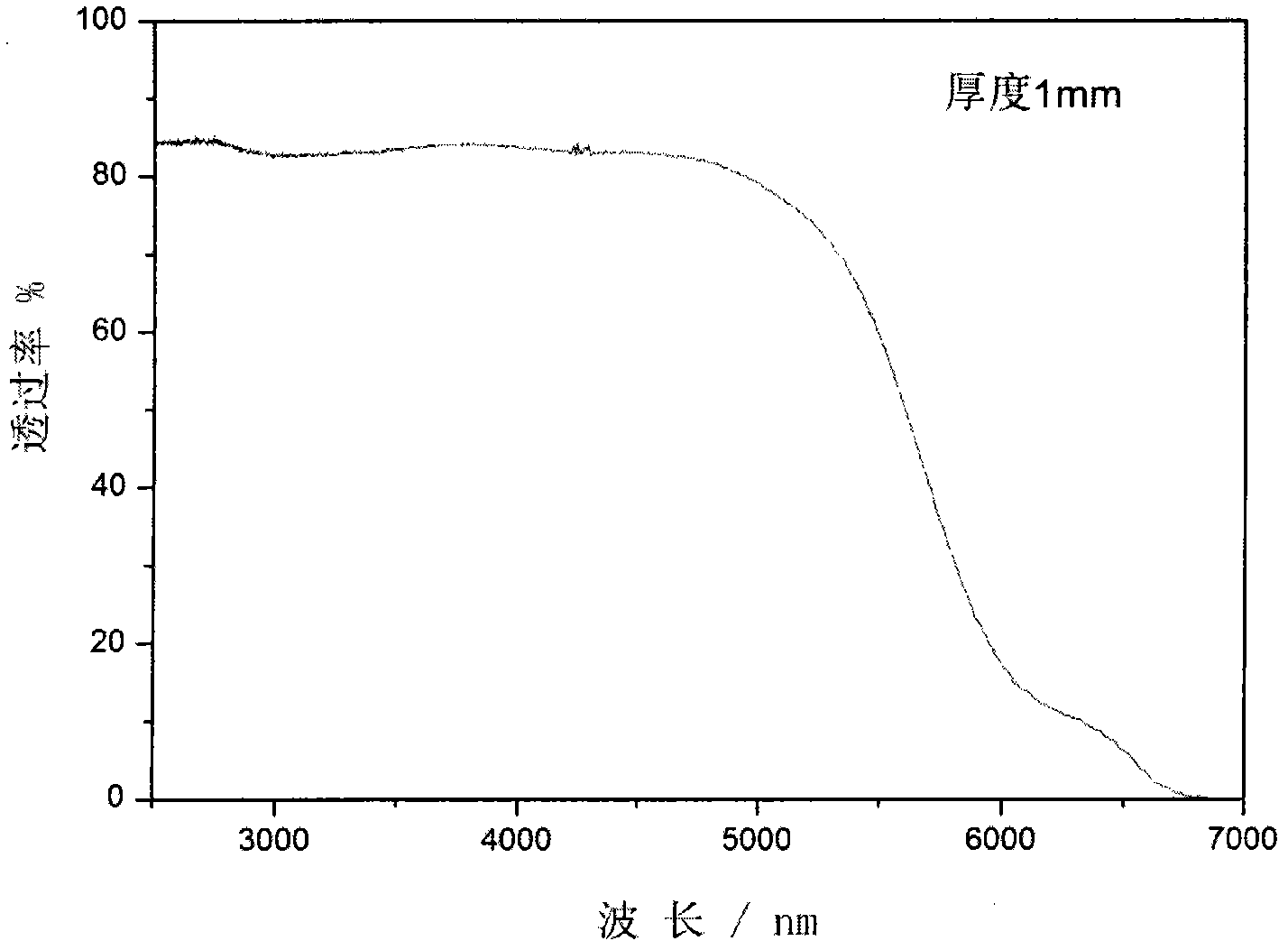

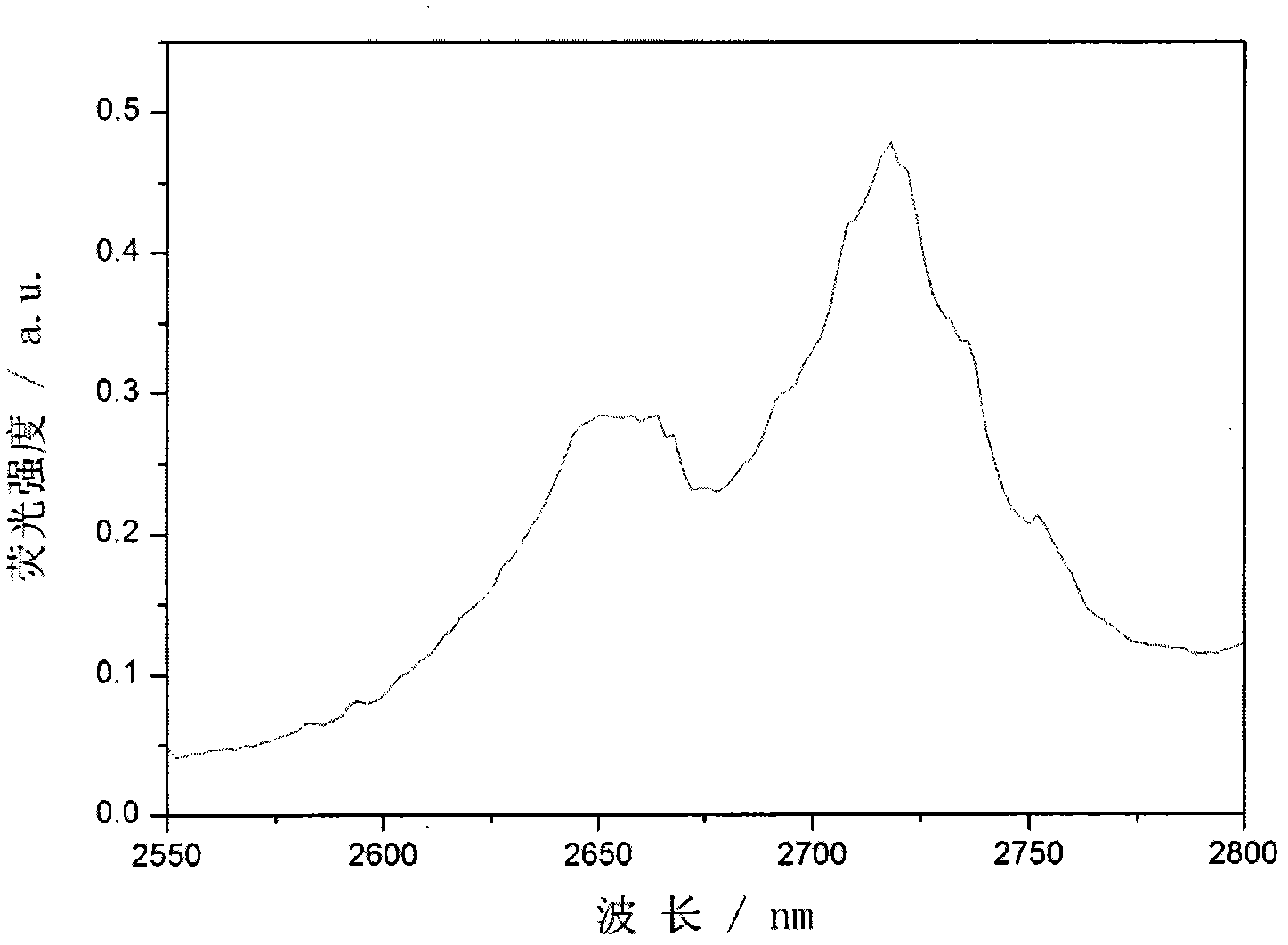

3mu m luminous rare-earth ion-doped fluogermanate laser glass and preparation method thereof

A technology of laser glass and fluorogermanate, which is applied in the field of 3μm luminescent rare earth ion-doped fluorogermanate laser glass and its preparation, and can solve the problems such as inability to obtain fluorescence emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

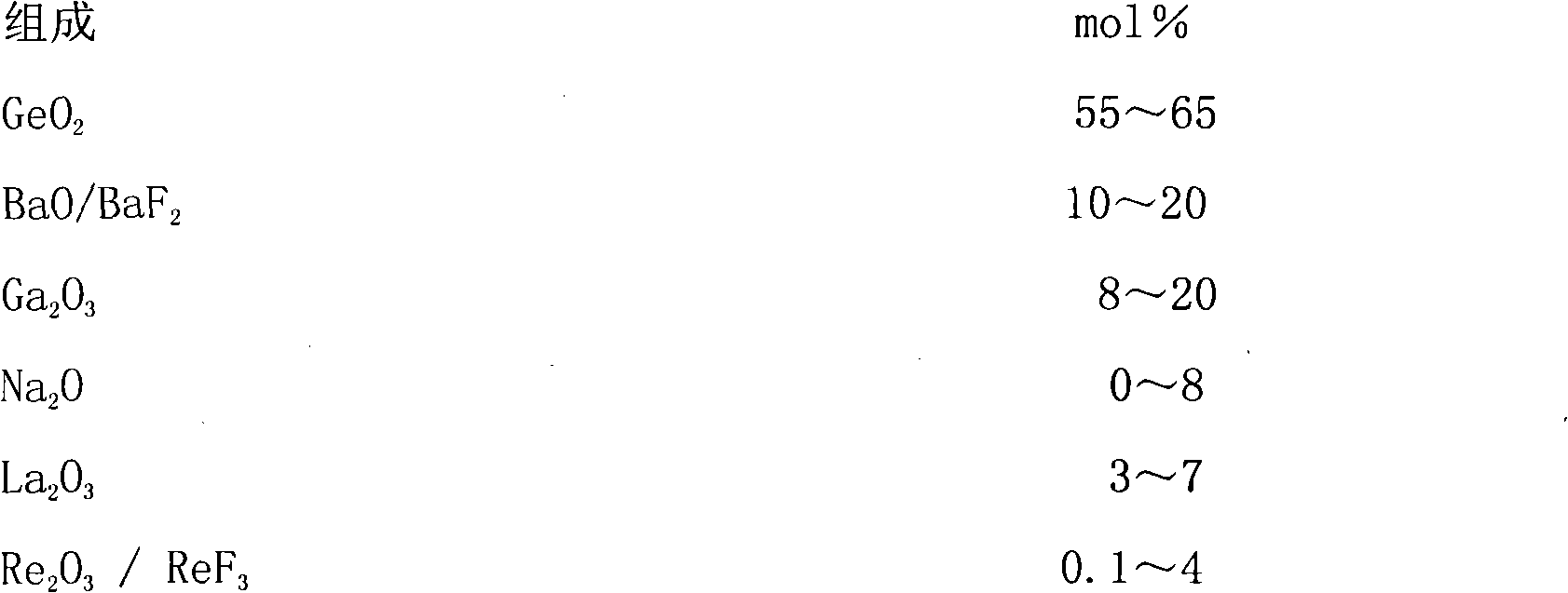

[0027] Composition is as shown in 1# in table 1, and concrete preparation process is as follows:

[0028] ①: After selecting the glass composition and the corresponding mole percentage shown in 1# in Table 1, calculate the weight of each component of the glass according to the mole percentage of the glass composition, then weigh the raw materials and mix them evenly;

[0029] ②: Put the mixture into a platinum crucible and melt it in a silicon carbon rod electric furnace at 1300°C for 45 minutes;

[0030] ③: After the glass is melted, the temperature is lowered to 1200°C, and high-purity oxygen is introduced to remove water, and the ventilation time is determined by the amount of raw material ratio;

[0031] ④: After raising the temperature of the glass liquid to 1350°C for clarification and homogenization, cool down to 1300°C for stirring. During this process, pure oxygen has been passed through for atmosphere protection;

[0032] ⑤: Quickly pour the glass onto the preheate...

Embodiment 2

[0035] Composition is as shown in 2# in table 1, and concrete preparation process is as follows:

[0036] ①: After selecting the composition of the glass shown in 2# in Table 1 and the corresponding mole percentage, calculate the weight of each component of the glass according to the mole percentage of the glass composition, then weigh the raw materials and mix them evenly;

[0037] ②: Put the mixture into a platinum crucible and melt it in a silicon carbon rod electric furnace at 1350 °C, and the melting time is controlled at 60 minutes;

[0038] ③: After the glass is melted, the temperature is lowered to 1200°C, and high-purity oxygen is introduced to remove water, and the ventilation time is determined by the amount of raw material ratio;

[0039] ④: After raising the temperature of the glass liquid to 1350°C for clarification and homogenization, cool it down to 1300°C for stirring. During this process, pure oxygen has been passed through for atmosphere protection;

[0040...

Embodiment 3

[0043] Composition is as shown in 3# in table 1, and concrete preparation process is as follows:

[0044] ①: According to 3# in Table 1, after selecting the composition of the glass and the corresponding mole percentage, calculate the weight percentage of each component of the glass according to the mole percentage of the glass composition, then weigh the raw materials and mix them evenly;

[0045] ②: Put the mixture into a platinum crucible and melt it in a silicon carbon rod electric furnace at 1320 °C, and the melting time is controlled at 50 minutes;

[0046] ③: After the glass is melted, the temperature is lowered to 1200°C, and high-purity oxygen is introduced to remove water, and the ventilation time is determined by the amount of raw material ratio;

[0047] ④: After raising the temperature of the glass liquid to 1350°C for clarification and homogenization, cool down to 1300°C for stirring. During this process, pure oxygen was passed through for atmosphere protection. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| infrared transmittance | aaaaa | aaaaa |

| infrared transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com