Infrared window protective film material, use thereof and preparation method thereof

A technology of infrared window and infrared optical window, applied in the field of infrared optical thin film, can solve the problems of large film stress, harsh deposition conditions of diamond film, preparation of diamond protective film, etc., and achieve the effect of good performance and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

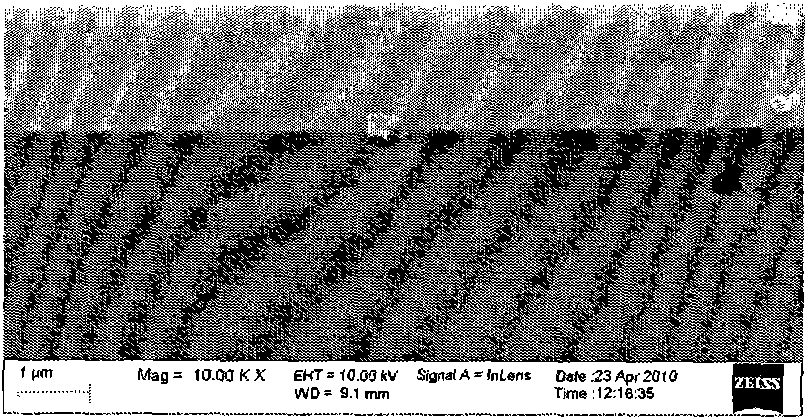

[0026] 1. Select the sputtering method of the physical vapor deposition method to prepare the required (Zr, Hf)Nx nitride thin film.

[0027] 2. Vacuumize the reaction chamber to below 6×10^-3Pa, turn on the substrate heater during the vacuuming process, set the temperature at 300°C, feed argon, the flow rate is 8.0sccm, and the reaction chamber pressure is 0.50~ 0.54Pa, turn on the RF power supply, adjust the substrate bias to -300V, and perform pre-sputtering for 20 minutes. During this process, the target and the target are separated by a baffle.

[0028] 3. After pre-sputtering, turn off the substrate power supply, adjust the argon gas flow rate to 2.5 sccm, open the nitrogen gas flow valve, adjust the nitrogen gas flow rate so that the N2 / Ar flow ratio is 0.72, and adjust the target power supply to set the input power to 100-300W. Remove the baffle to start deposition, the deposition pressure is 0.34-0.41Pa, and the deposition time is 60 minutes.

[0029] 4. After the de...

Embodiment 2

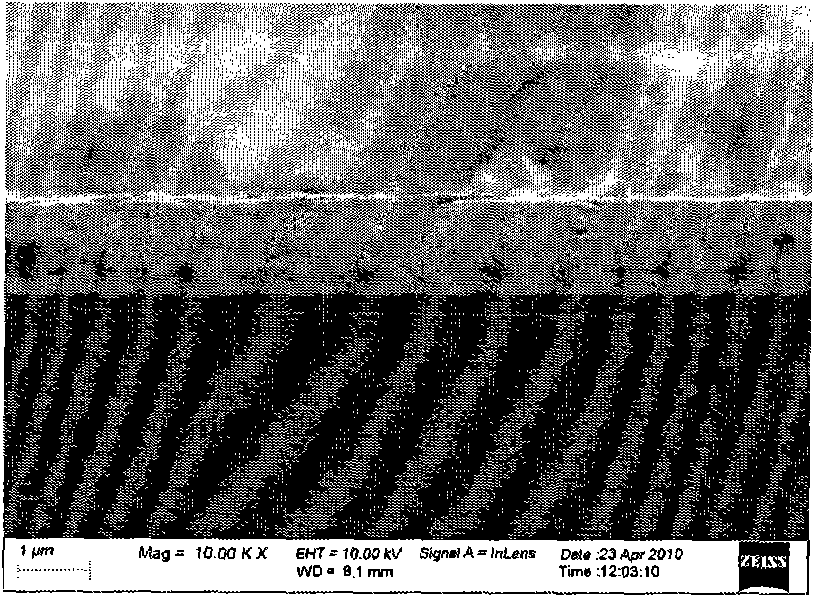

[0040] 1. Select the plasma-assisted chemical vapor deposition method to prepare the required (Zr, Hf)Nx nitride thin film.

[0041] 2. Vacuumize the reaction chamber to below 6×10^-3Pa, turn on the substrate heater during the vacuuming process, set its temperature to 500°C, pass in Ar to etch for 5 minutes, the Ar flow rate is 10sccm, and the reaction Chamber pressure 5000±100Pa.

[0042] 3. After etching, close the Ar flowmeter, evacuate to below 6×10^-3Pa again, feed ammonia gas and Zr tetrachloride or Hf tetrachloride, the flow rates are 25 sccm and 5 sccm respectively, and adjust the pressure of the reaction chamber to 5000Pa, turn on the RF power supply, adjust the power to 500W, and start the chemical vapor deposition of (Zr, Hf) nitride film. During the deposition process, the gas flow rate is kept constant, the reaction chamber pressure is kept between 5000±100Pa, and the deposition time is 60 minutes.

[0043] 4. After the deposition is completed, the temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com