Temperature-adjustable fabric based on carbon nano tube and preparing method of fabric

A technology of carbon nanotubes and carbon nanotube layers, which is applied in the temperature-adjustable fabric based on carbon nanotubes and its preparation, and in the field of temperature-adjustable fabrics, which can solve the problems of not being able to match human infrared radiation, poor wearability, and affecting comfort, etc. , to achieve good composite effect, good flexibility and light characteristics, and improve the effect of thick and heavy shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

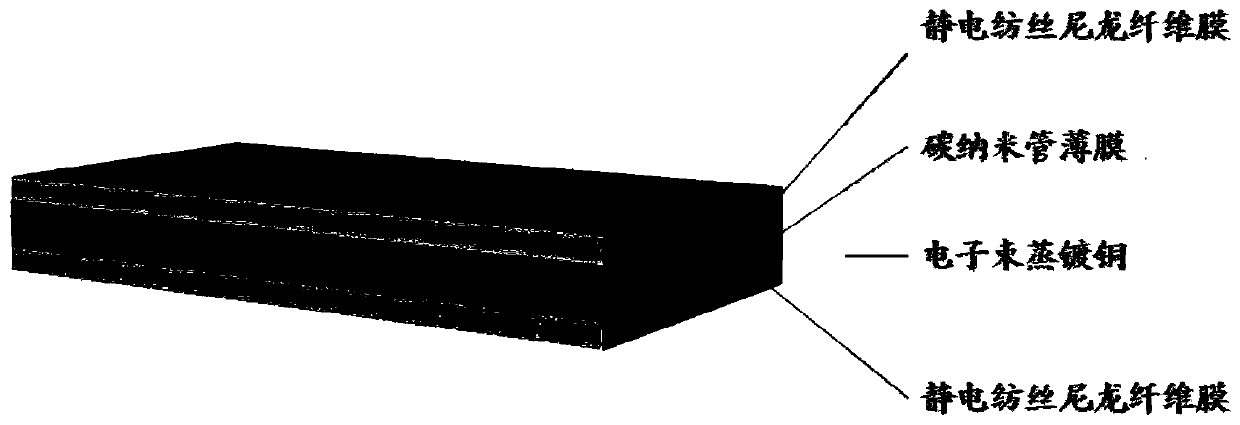

[0053] As another aspect of the technical solution of the present invention, what it relates to is the preparation method of the aforementioned carbon nanotube-based temperature-adjustable fabric, which includes:

[0054] Provide carbon nanotube films;

[0055] Depositing a metal layer on the surface of the carbon nanotube film to form an inner structure layer; and,

[0056] At least the outer structural layer covers the first surface and the second surface of the inner structural layer, the first surface and the second surface are arranged opposite to each other in the thickness direction of the inner structural layer, and the outer structural layer has holes structure and allow infrared rays to pass through.

[0057] In one embodiment, the preparation method includes: using electron beam evaporation technology to deposit a metal layer on the surface of the carbon nanotube film, wherein the evaporation deposition rate is The deposition time is 300-800s.

[0058] Further, ...

Embodiment 1

[0077] see figure 1 As shown, the specific preparation steps of the temperature-adjustable fabric based on carbon nanotubes in this embodiment are as follows:

[0078] 1) Carbon nanotube film: a carbon nanotube film prepared by floating catalyst chemical deposition (CVD) with a thickness of 10 μm (Suzhou Jiedi Nano Technology Co., Ltd.).

[0079] 2) Electron beam evaporation copper: use a vacuum electron beam coating machine (Chengdu Modern Nanguang Vacuum Equipment Co., Ltd.) to plate copper on the carbon nanotube film, set the copper plating deposition speed to The deposition time is 400s, and finally a 180nm copper layer is plated on the carbon nanotube film.

[0080] 3) Prepare 22% nylon formic acid solution: weigh 22g of nylon (PA6) solid particles, mix with 78g of formic acid at room temperature, and place on a magnetic stirring heating platform at 50°C for 1 hour to fully dissolve the nylon particles in formic acid. After cooling, a 22% nylon formic acid solution was...

Embodiment 2

[0086] see figure 1 As shown, the specific preparation steps of the temperature-adjustable fabric based on carbon nanotubes in this embodiment are as follows:

[0087] 1) Carbon nanotube film: a carbon nanotube film prepared by floating catalyst chemical deposition (CVD) with a thickness of 11 μm (Suzhou Jiedi Nano Technology Co., Ltd.).

[0088] 2) Electron beam evaporation copper: use a vacuum electron beam coating machine (Chengdu Modern Nanguang Vacuum Equipment Co., Ltd.) to plate copper on the carbon nanotube film, set the copper plating deposition speed to The deposition time is 300s, and finally a 120nm copper layer is plated on the carbon nanotube film.

[0089] 3) Prepare 22% nylon formic acid solution: weigh 22g of nylon (PA6) solid particles, mix with 78g of formic acid at room temperature, and place on a magnetic stirring heating platform at 50°C for 1 hour to fully dissolve the nylon particles in formic acid. After cooling, a 22% nylon formic acid solution was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com