Ceramic polyurethane composite board and its production

The technology of a polyurethane board and a production method, which is applied in the field of composite boards, can solve the problem that the polyurethane board can no longer be composited with ceramic tiles, and achieves the effects of high production efficiency, simple process and good composite effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

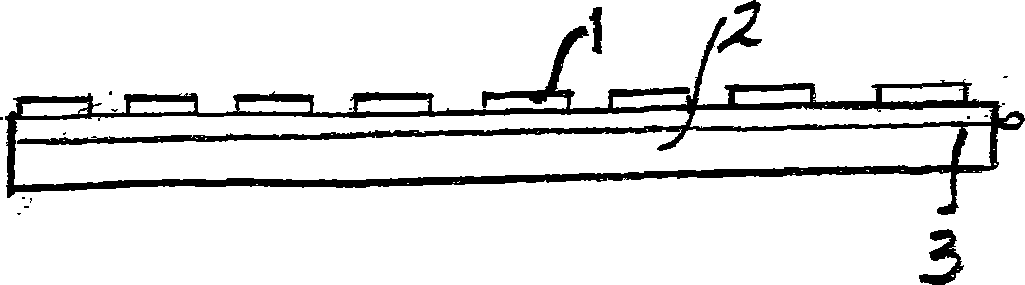

[0012] A method for producing polyurethane composite boards for ceramic facing tiles. The ceramic facing tiles 1 are matched according to required patterns and colors, placed on the production line with the back facing up, and polyurethane foaming material is sprayed on the back of the ceramic facing tiles for foaming. The press pressurizes to obtain the polyurethane composite board of the ceramic veneer brick. During the foaming process, the wall connector 3 is also placed on the ceramic tile. The formed ceramic veneer polyurethane composite board includes a ceramic veneer layer 1, and the ceramic veneer layer 1 and the polyurethane plate 2 are composited into one body through the above-mentioned polyurethane foaming and pressing. The polyurethane board 2 is provided with a wall connector 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com