Forming equipment for continuous fiber reinforced composite pipe

A molding equipment and enhanced compounding technology, which is applied in the field of composite pipes, can solve problems such as the inability to realize the co-extrusion of continuous fiber composite pipes and the difference in shear strength of pipe performance, and achieve improved molding quality, good bonding effects, and good composite effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is a specific embodiment of the present invention and in conjunction with the accompanying drawings, further describes the technical solution of the present invention, but the present invention is not limited to this embodiment.

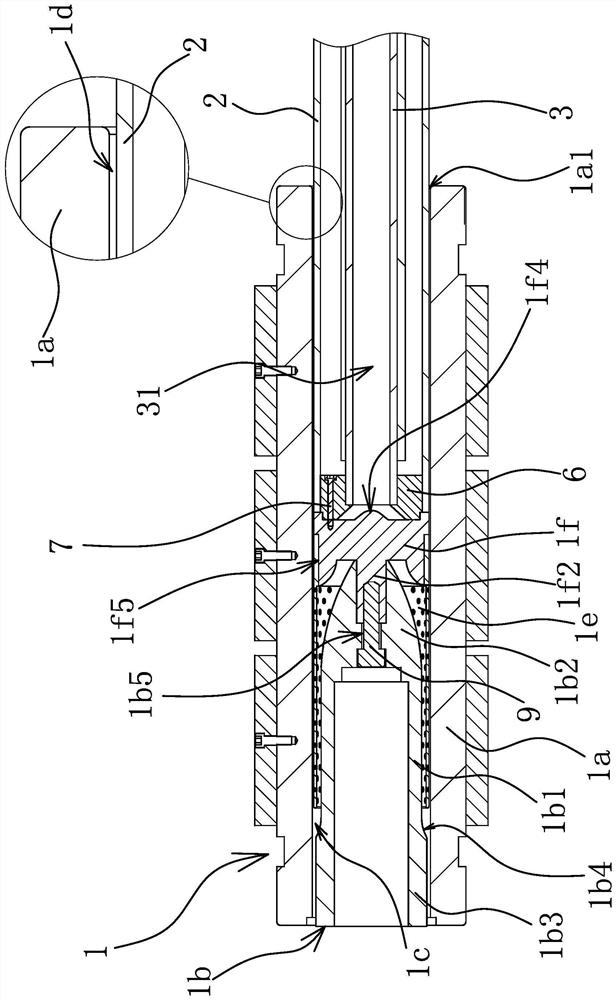

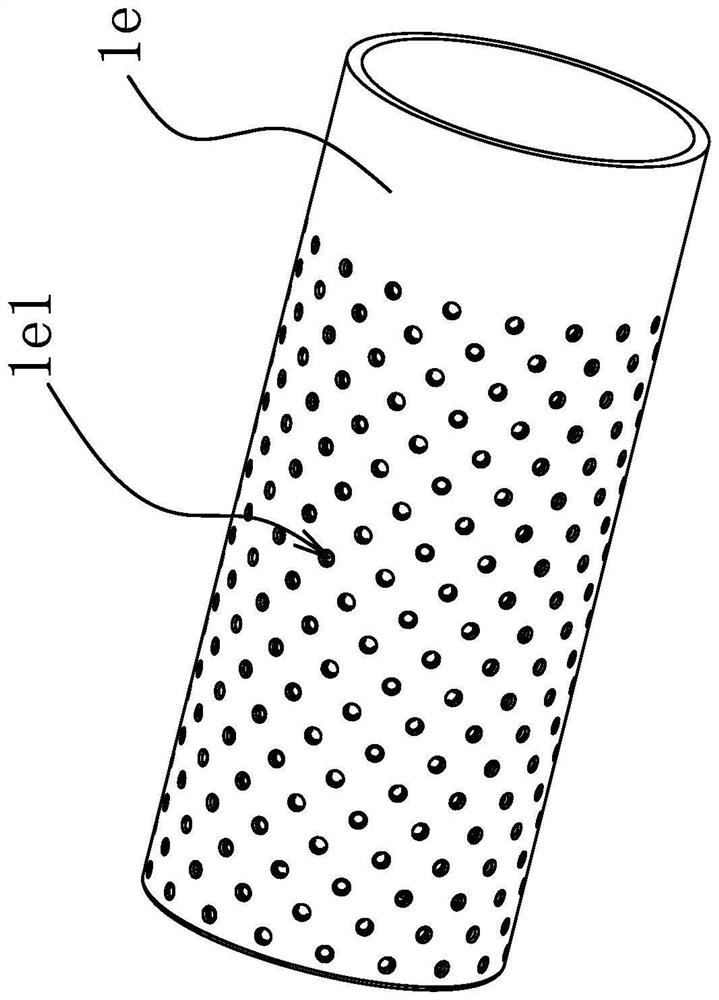

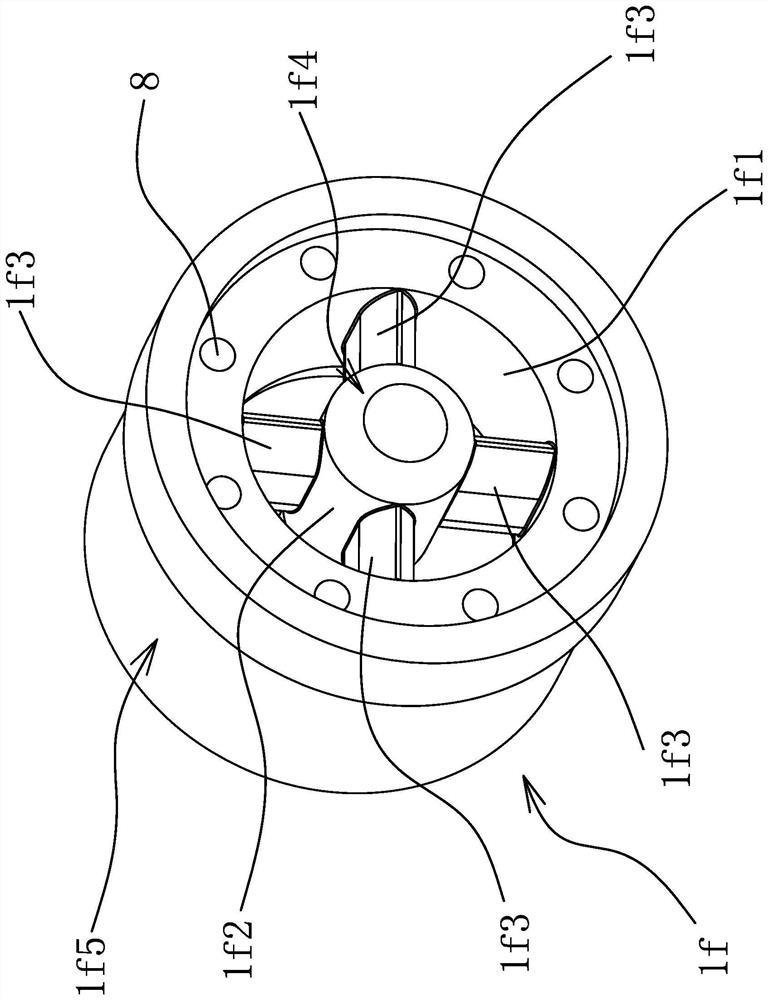

[0028] The molding equipment of this compound pipe comprises molding die 1, winding machine 5, extruder 4 etc., as figure 1 As shown, a molding cavity 1c is formed between the outer mold cover 1a and the core mold 1b of the forming mold 1. The molding equipment also includes an outer tube 2, and one end of the outer tube 2 extends into the outer tube 1 through the front port 1a1 of the outer mold cover 1a. In the mold casing 1a, an annular cavity 1d is formed between the outer peripheral wall of the outer tube 2 and the inner peripheral wall of the outer mold casing 1a for the reinforcement fiber to pass through, and the forming cavity 1c is provided with a cylinder sleeved outside the core mold 1b shaped support cylinder 1e, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com