Copper sulphide-doped cubic crystal zinc sulfide material and preparation method thereof

A technology of cubic crystal and zinc sulfide, applied in the field of high-efficiency infrared transmission materials, can solve the problems of crystal transformation, affecting the infrared performance of materials, reducing the infrared transmittance of materials, etc., and achieves low cost, easy reaction and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

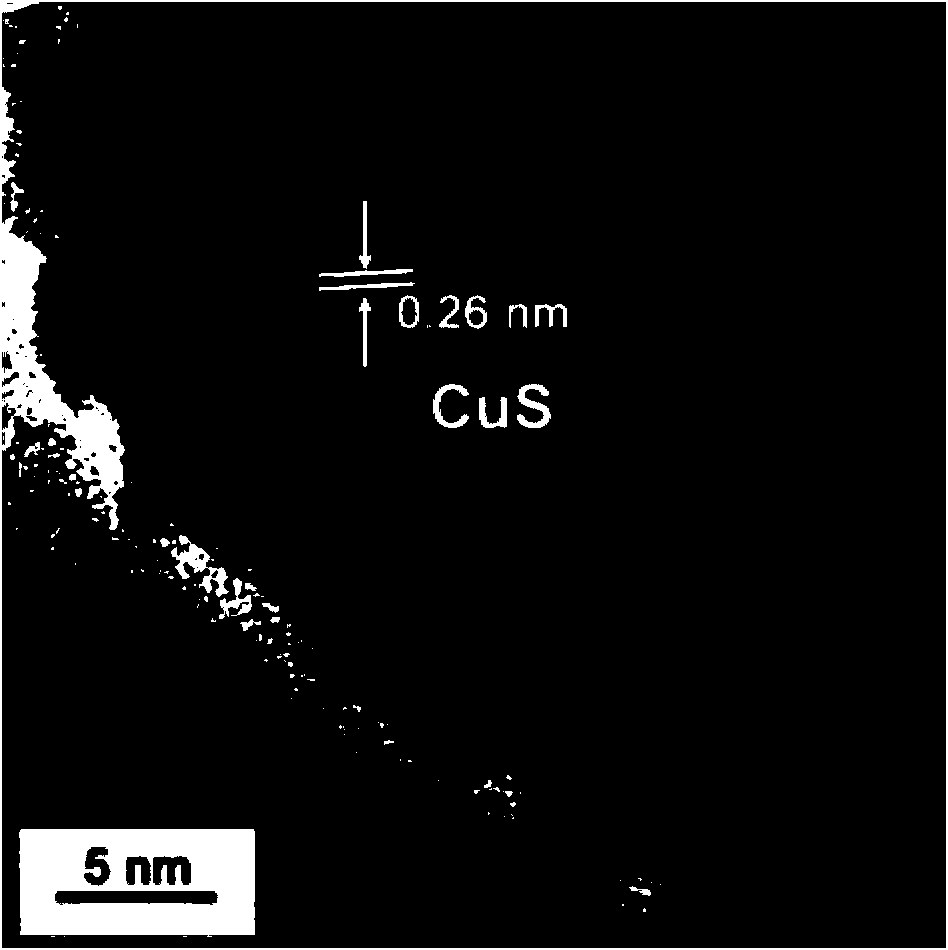

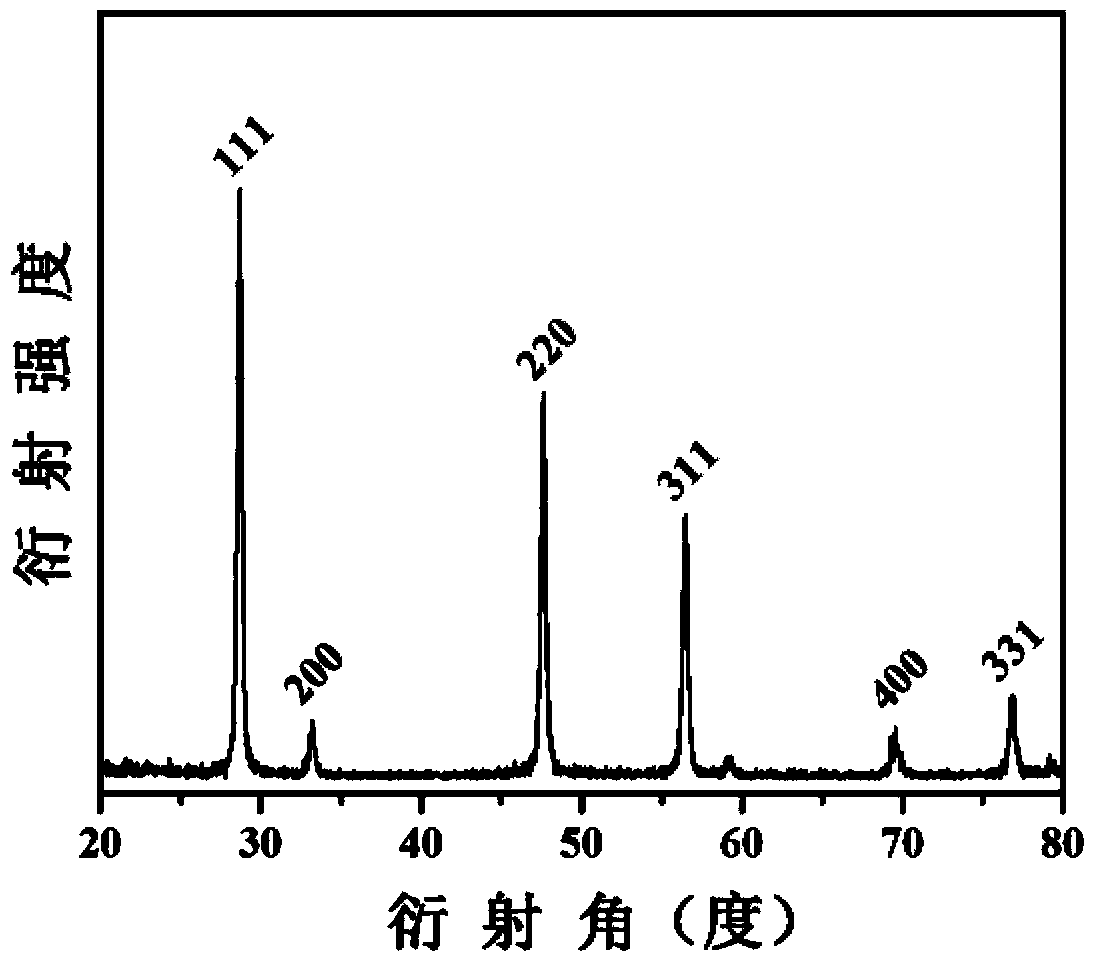

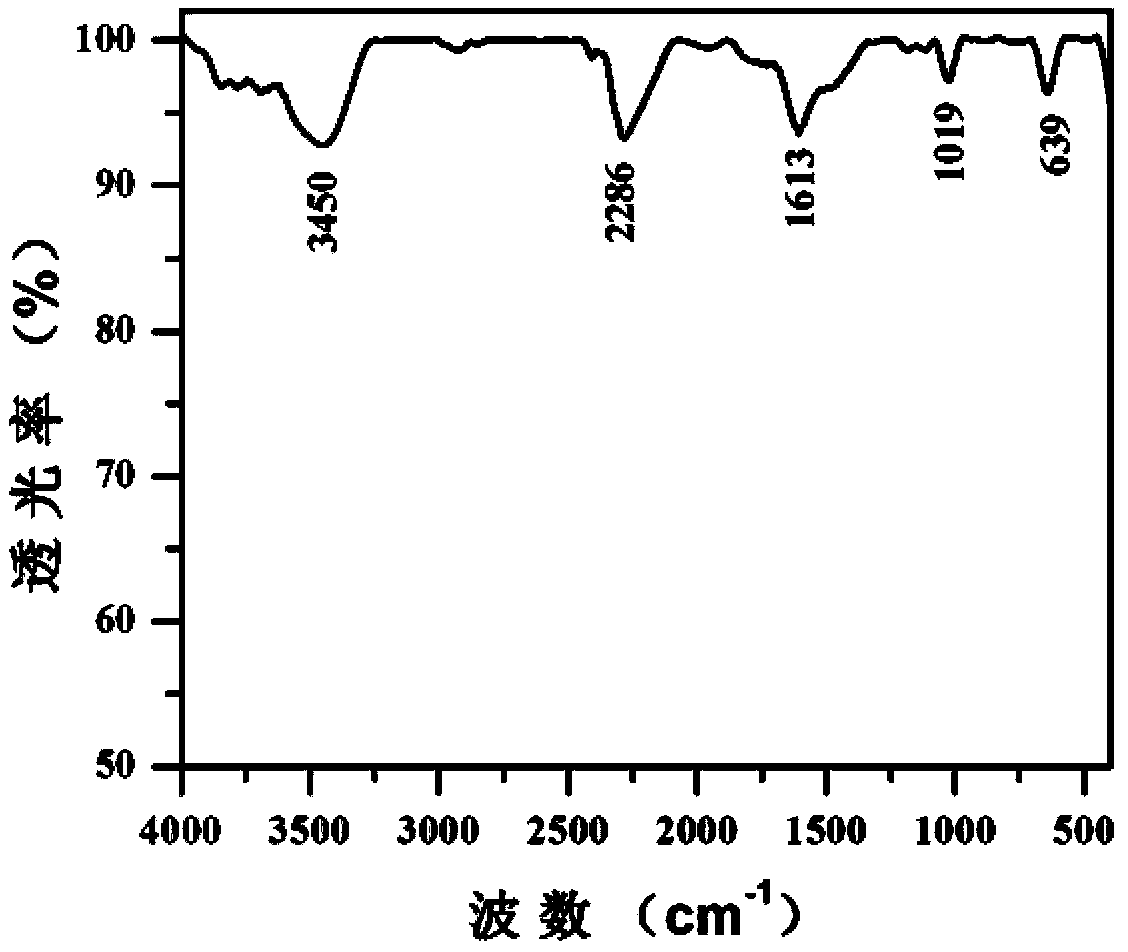

Method used

Image

Examples

Embodiment 1

[0028] Step A: take by weighing 44.624g (150mmol) Zn (NO 3 ) 2 ·6H 2 O, 0.181g (0.75mmol) Cu(NO 3 ) 2 ·3H 2 O was dissolved in 150 mL deionized water to prepare a mixed salt solution.

[0029] Step B: Weigh 79.259g (330mmol) Na 2 S·9H 2 O was dissolved in 150 mL of deionized water to prepare a sodium sulfide solution.

[0030] Step C: the mixed salt solution prepared in step A and the sodium sulfide solution prepared in step B are mixed in a volume ratio of 1:1, and the mixture is mixed at 10.0mL min -1 The dropping rate was added to the rotating liquid film reactor to nucleate rapidly, and the obtained slurry was crystallized at 200 °C for 24 hours, filtered, washed, and dried to obtain a ZnS / CuS sample with a CuS doping amount of 0.50wt%.

Embodiment 2

[0032] Step A: Weigh 29.749g (100mmol) Zn(NO 3 ) 2·6H 2 O, 0.242g (1mmol) Cu(NO 3 ) 2 ·3H 2 O was dissolved in 100 mL deionized water to prepare a mixed salt solution.

[0033] Step B: Weigh 52.840g (220mmol) Na 2 S·9H 2 O was dissolved in 100 mL of deionized water to prepare a sodium sulfide solution.

[0034] Step C: the mixed salt solution prepared in step A and the sodium sulfide solution prepared in step B are mixed in a volume ratio of 1:1, and the mixture is mixed at 10.0mL min -1 The dropping rate was added to the rotating liquid film reactor to nucleate rapidly, and the resulting slurry was crystallized at 200 °C for 24 hours, filtered, washed, and dried to obtain a ZnS / CuS sample with a CuS doping amount of 1.00wt%.

Embodiment 3

[0036] Step A: Weigh 29.749g (100mmol) Zn(NO 3 ) 2 ·6H 2 O, 0.024g (0.1mmol) Cu(NO 3 ) 2 ·3H 2 O was dissolved in 100 mL deionized water to prepare a mixed salt solution.

[0037] Step B: Weigh 52.840g (220mmol) Na 2 S·9H 2 O was dissolved in 100 mL of deionized water to prepare a sodium sulfide solution.

[0038] Step C: the mixed salt solution prepared in step A and the sodium sulfide solution prepared in step B are mixed in a volume ratio of 1:1, and the mixture is mixed at 10.0mL min -1 The dropping rate was added to the rotating liquid film reactor to nucleate rapidly, and the obtained slurry was crystallized at 200 °C for 24 hours, filtered, washed, and dried to obtain a ZnS / CuS sample with a CuS doping amount of 0.10wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com