HJT battery and preparation method thereof

A battery and electrode technology, which is applied in the field of solar cells, can solve the problems of heterojunction cell open voltage and fill factor drop, limit the effective use of long-wavelength solar energy, and single-layer ITO thin films cannot meet the needs, etc., to achieve good conductivity , low light absorption, and the effect of reducing the hole barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

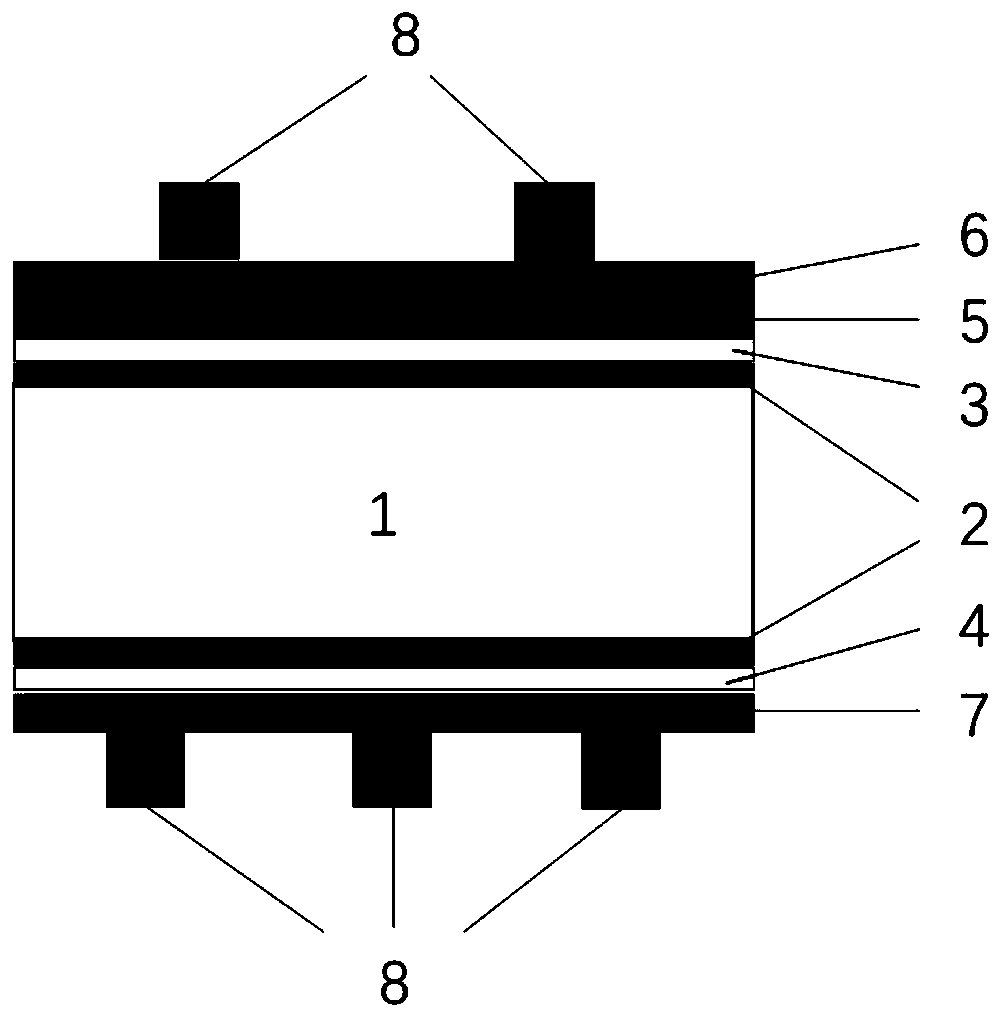

[0035] Such as figure 1As shown, a HJT battery includes an N-type silicon chip 1, the light-receiving surface and the backlight surface of the N-type silicon chip 1 are respectively provided with an intrinsic amorphous silicon layer 2, and the intrinsic amorphous silicon layer 2 on the light-receiving surface of the N-type silicon chip 1 A P-type doped amorphous silicon layer 3 is arranged on the silicon layer 2, an N-type doped amorphous silicon layer 4 is arranged on the intrinsic amorphous silicon layer 2 on the backlight surface of the N-type silicon wafer 1, and a P-type doped amorphous silicon layer 4 is arranged on the silicon layer 2. The silicon layer 3 is provided with an IMO layer 5 and an ITO layer 6 in sequence, an ITO conductive film layer 7 is provided on the N-type doped amorphous silicon layer 4, and a metal grid line electrode is provided on the ITO layer 6 and the ITO conductive film layer 7 respectively. 8.

[0036] In this embodiment, the work function of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com