Single-component mildewproof negative-radical polyurethane building sealant and preparation method thereof

A polyurethane, one-component technology, applied in the field of sealants, can solve problems such as affecting the service life of buildings, no mildew and root resistance, and sealants without root resistance, and achieves good water removal effect, long shelf life, and good bonding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

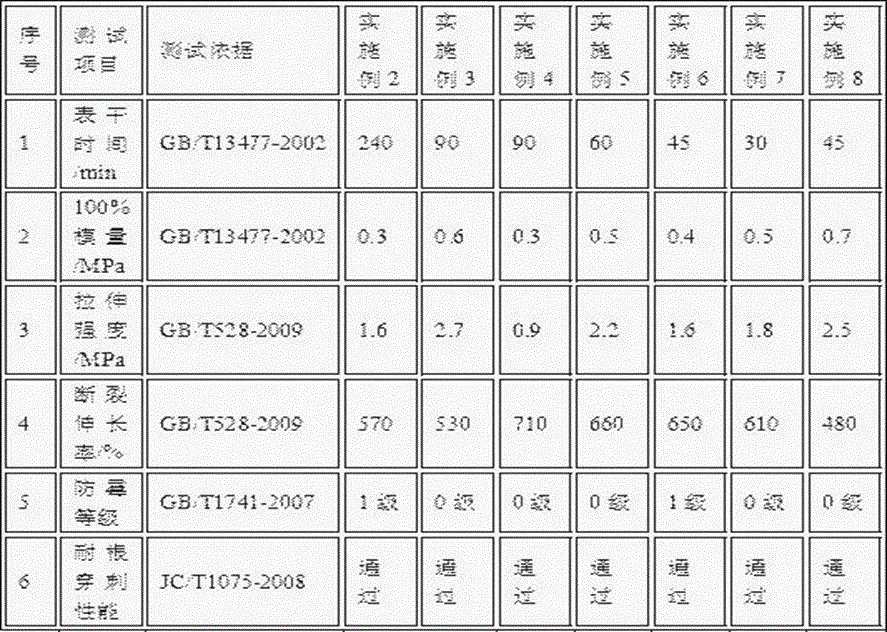

Examples

Embodiment 1

[0085] A single-component anti-mildew and root-resistance polyurethane building sealant, which comprises the following components by weight percentage:

[0086] Polyurethane prepolymer 30% ~ 70%

[0087] Antifungal agent 1% ~ 5%

[0088] Chemical root inhibitor 1% ~ 7%

[0089] Filler 20%~55%

[0090] Silane adhesion promoter 1% to 3%

[0091] Catalyst 0.1%~1%

[0092] Moisture scavenger 0.1% ~ 0.5%;

[0093] Wherein, the polyurethane prepolymer comprises the following components in weight percent:

[0094] Polyoxypropylene diol 25%~60%

[0095] Polyoxypropylene triol 10%~30%

[0096] Polyisocyanate 5%~10%

[0097] Plasticizer 20% to 50%.

[0098] Among them, the antifungal agent is a substance that does not contain active H, specifically silver-loaded zeolite, silver-loaded molecular sieve, silver-loaded activated carbon, nano-titanium dioxide, nano-zinc oxide, isothiazolinone compounds, pyrazole compounds, thiophene compounds, One or a mixture of two or more azirid...

Embodiment 2

[0121] A single-component anti-mildew and root-resistance polyurethane building sealant, which comprises the following components by weight percentage:

[0122] Polyurethane prepolymer 53%

[0123] Silver loaded molecular sieve 2%

[0124] chemical root inhibitor B 2 3%

[0125] Ground calcium carbonate 13%

[0126] PVC paste resin 7%

[0127] Light calcium carbonate 20%

[0128] γ-Glycidyl etheroxypropyl triethoxysilane 1.5%

[0129] Dibutyltin dilaurate 0.2%

[0130] p-methylsulfonyl isocyanate 0.3%;

[0131] Wherein, the polyurethane prepolymer comprises the following components by weight percentage:

[0132] Polyoxypropylene glycol 33%

[0133] Polyoxypropylene Triol 14.5%

[0134] Diphenylmethane diisocyanate 5.5%

[0135] Dioctyl phthalate 47%;

[0136] Wherein, the molecular weight of polyoxypropylene triol is 2000, and the molecular weight of polyoxypropylene diol is 6000.

[0137] In this embodiment, the polyurethane prepolymer is prepared by the following ...

Embodiment 3

[0151] A single-component anti-mildew and root-resistance polyurethane building sealant, which comprises the following components by weight percentage:

[0152] Polyurethane prepolymer 48%

[0153] Silver loaded activated carbon 4.5%

[0154] chemical root inhibitor B 5 4%

[0155] Ground calcium carbonate 17%

[0156] Carbon black 5%

[0157] Calcined kaolin powder 19%

[0158] Gamma-ureidopropyltriethoxysilane 1.4%

[0159] Stannous octoate 0.8%

[0160] p-methylsulfonyl isocyanate 0.3%;

[0161] Wherein, the polyurethane prepolymer comprises the following components by weight percentage:

[0162] Polyoxypropylene glycol 35%

[0163] Polyoxypropylene Triol 24%

[0164] Toluene diisocyanate 8.2%

[0165] Dioctyl phthalate 12.8%

[0166] Dinonyl phthalate 20%;

[0167] Wherein, the molecular weight of polyoxypropylene triol is 3000, and the molecular weight of polyoxypropylene diol is 6000.

[0168] In this embodiment, the polyurethane prepolymer is prepared by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com