Electrolyte for improving high temperature performance of lithium manganate power battery and lithium manganate power battery

A power battery and high-temperature performance technology, which is applied in the field of lithium-ion power batteries, can solve the problems of positive electrode loss of activity and poor cycle performance of lithium manganate batteries, and achieve the effects of suppressing capacity decay, significant water removal effect, and improving high-temperature cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

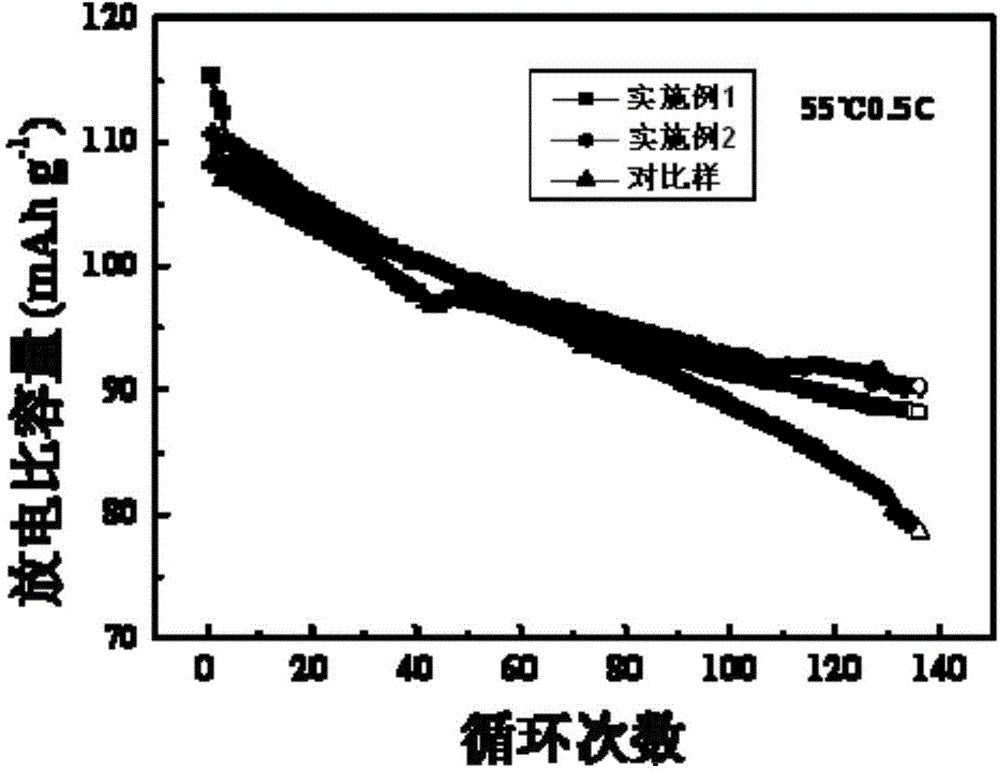

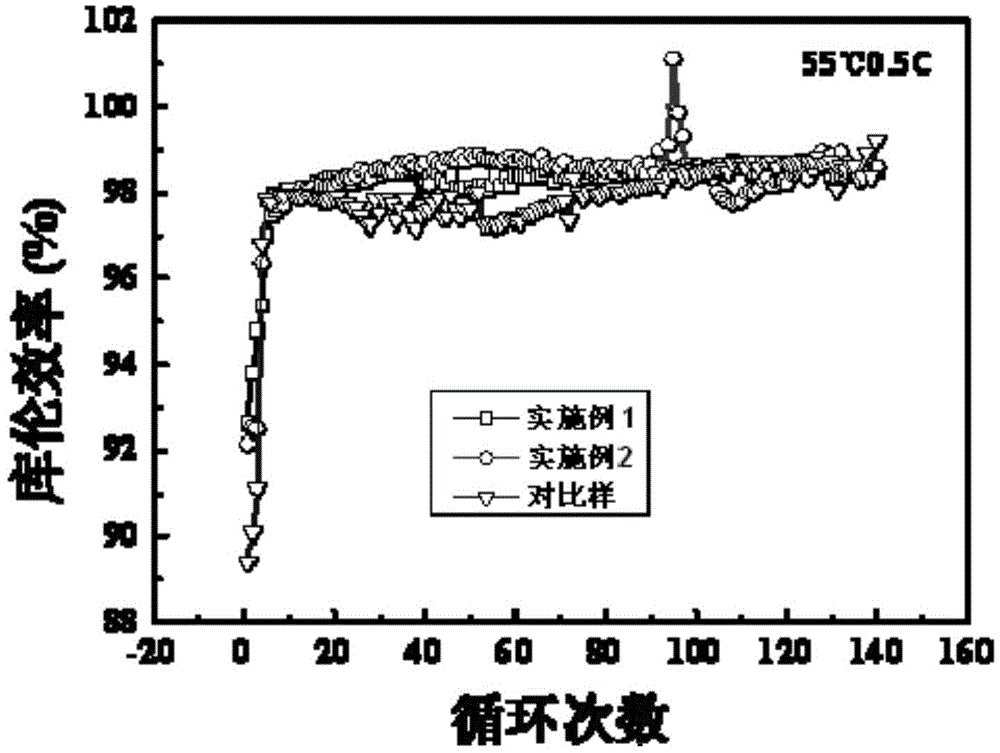

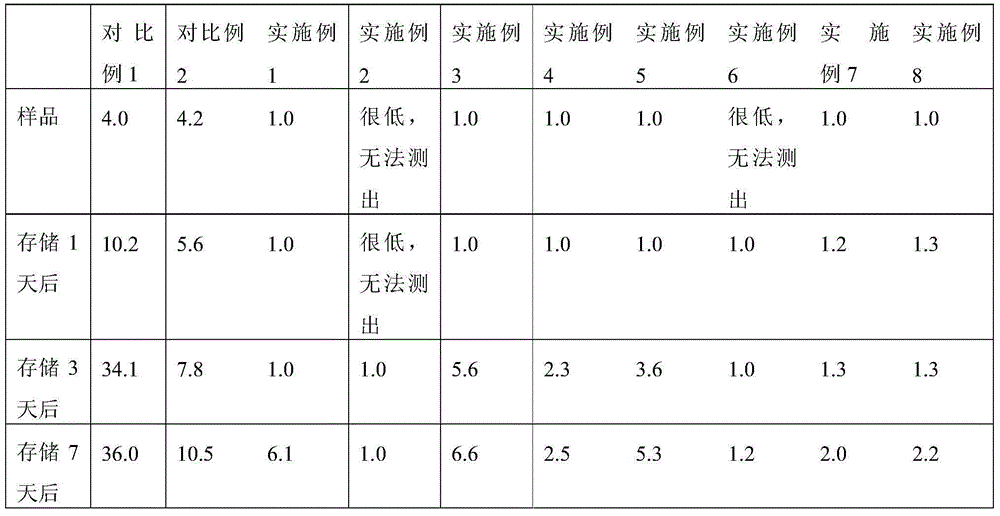

Embodiment 1

[0041] At room temperature, weigh ethylene carbonate (EC) 76.81g, ethyl methyl carbonate (EMC) 25.92g, diethyl carbonate (DEC) ) 127g, propylene carbonate (PC) 25.27g, and additives ethylene carbonate (VC) 3g, methylene disulfonate (MMDS) 3g, lithium iodide (LiI) 0.0015g, hexamethyldisilazane 0.0015g, perfluorooctanesulfonate diethanolamide 3g, lithium bis(fluorosulfonyl)imide (LiFSI) 6g, lithium bisoxalate borate (LiBOB) 6g and lithium hexafluorophosphate (LiPF 6 ) 24g; take out EC, EMC, and DEC respectively and pour them into a beaker placed on a magnetic stirrer, control the stirring rate and then add LiPF to the solvent system in turn 6 , LiBOB, and LiFSI were stirred for 5 to 10 minutes until the lithium salt was completely dissolved, then weighed the removed high-temperature additives, film-forming additives, surfactants, and stabilizers and added them to the above beaker in sequence, and continued to stir until the mixture was evenly mixed to obtain Non-aqueous electro...

Embodiment 2

[0044] In addition to replacing 3g of ethylene carbonate (VC) with 1.5g of vinyl acetate (VA) and 1.5g of ethylene carbonate (VC), 0.0015g of hexamethyldisilazane was replaced with 0.0015g of heptamethyldisilazane, Except that 6g of lithium bisoxalate borate (LiBOB) was changed to 6g of LiODFB, an electrolyte sample was obtained in the same manner as in Example 1 and a battery test was performed.

Embodiment 3

[0046] In addition to replacing 3g of ethylene carbonate (VC) with 1.5g of vinyl acetate (VA) and 1.5g of ethylene carbonate (VC), 3g of methylene disulfonate (MMDS) was replaced with methylene disulfonate ( MMDS) 1.5g and p-toluenesulfonic acid isocyanate (PTSI) 1.5g, lithium iodide (LiI) 0.0015g replaced by lithium sulfite (Li 2 SO 3 ) 0.0015g, lithium bisoxalate borate (LiBOB) 6g was replaced by LiODFB6g, obtained electrolyte sample in the same manner as in Example 1 and carried out battery test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com