High-efficiency device for water removal from flue gas

A high-efficiency, flue gas technology, used in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of low precision, low refrigeration efficiency, poor refrigeration effect, etc., to ensure the sealing effect, improve refrigeration efficiency, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

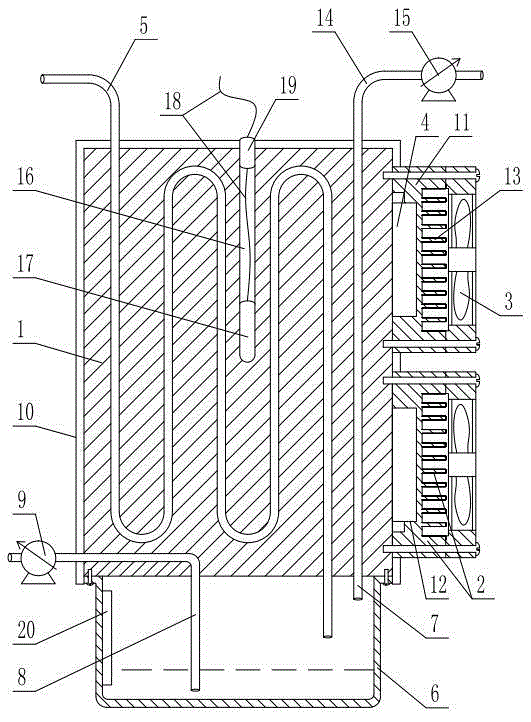

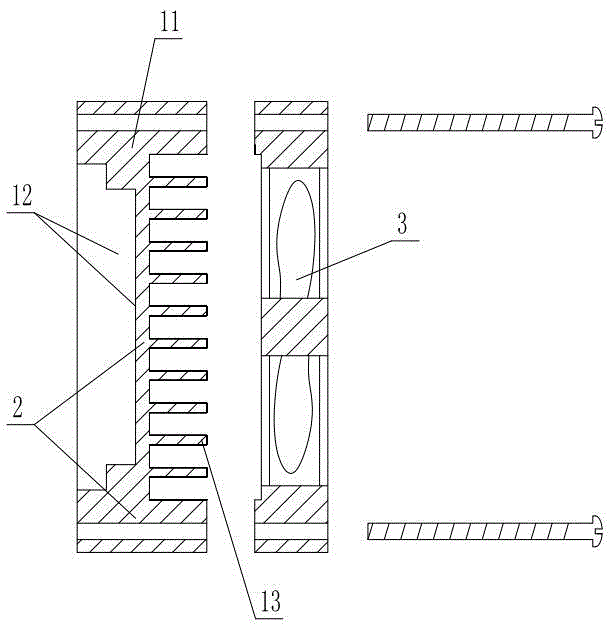

[0029] As shown in the figure, the high-efficiency flue gas dehydration device includes a refrigeration block 1, a fan 3 is installed on the outer wall of the refrigeration block through a mounting part 2, and a semiconductor cooling chip 4 is clamped between the outer wall of the cooling block and the mounting part. The refrigerating surface of the sheet is set close to the side wall of the refrigerating block, the heating surface of the semiconductor refrigerating sheet is set facing the fan, an air channel 5 is arranged in the refrigerating block, and a water storage bottle 6 connected with the output end of the air channel is sealed and connected to the lower end of the refrigerating block. The top of the water bottle is communicated with an air outlet pipe 7, and the bottom of the water storage bottle is communicated with a drain pipe 8, and a drainage mechanism is installed on the drain pipe.

[0030]This high-efficiency flue gas dehydration device achieves a moderate vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com