Separation method of 2-methyl-3-butyn-2-ol

A separation method and technology of butyne, applied in the separation/purification of hydroxy compounds, chemical instruments and methods, preparation of hydroxy compounds, etc., can solve the problems of product conversion rate and selectivity reduction, high content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

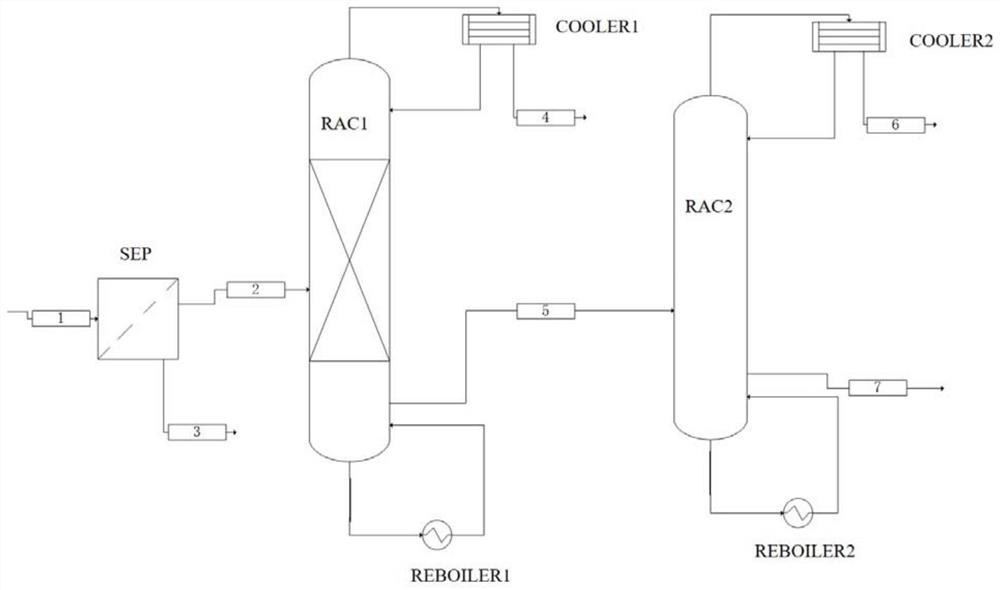

Method used

Image

Examples

Embodiment 1

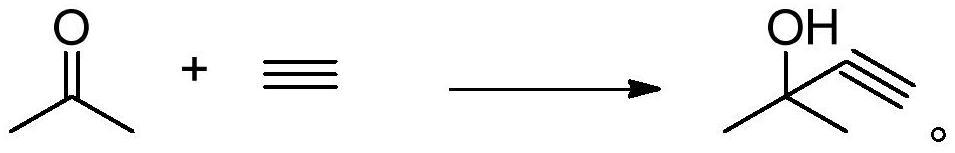

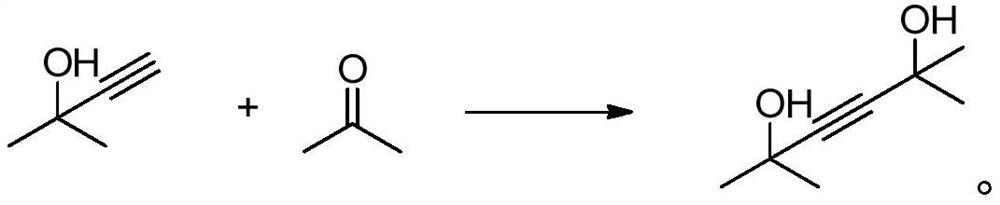

[0082] Embodiment 1: the preparation of 1# reaction solution

[0083] First, replace the 500L autoclave with ammonia gas three times, lower the temperature in the reactor to -20°C, add liquid ammonia (144.5Kg, 8500mol), start stirring, and feed acetylene (16800L, 750mol) at a concentration of 20wt%. Magnesium sulfate aqueous solution 43.5g and concentration are 50wt% potassium hydroxide aqueous solution (1008g, the potassium hydroxide consumption as solute is 3mol% of acetone), be warming up to 10 ℃ and add acetone (17.4Kg, 300mol), control acetone to add The feed rate is completed in about 1h; the reaction temperature is 10°C, and after 2h of reaction, 5Kg of ammonium sulfate aqueous solution with a concentration of 10wt% is added for neutralization to obtain 1# reaction containing 2-methyl-3-butyn-2-ol solution, and sampled to detect the reaction solution by GC.

[0084] The composition of 1# reaction solution: the content of inorganic salt is 2.16wt%, the content of water ...

Embodiment 2

[0085] Embodiment 2: the preparation of 2# reaction solution

[0086] First, replace the 500L autoclave with ammonia gas three times, lower the temperature in the reactor to -20°C, add liquid ammonia (144.5Kg, 8500mol), start stirring, and feed acetylene (16800L, 750mol) at a concentration of 20wt%. Zinc acetate aqueous solution 17.5g, then add concentration and be the potassium hydroxide aqueous solution (1008g of 50wt%, the potassium hydroxide consumption as solute is 3mol% of acetone), be warming up to 10 ℃ and add acetone (17.4Kg, 300mol), control The acetone addition rate is about 1h and the feed is completed; the reaction temperature is 10°C, and after 2 hours of reaction, 5Kg of ammonium sulfate aqueous solution with a concentration of 10wt% is added for neutralization to obtain 2-methyl-3-butyn-2-ol containing 2 #Reaction solution, and take a sample to detect the reaction solution by GC.

[0087] The composition of 2# reaction solution: the content of inorganic salt i...

Embodiment 3

[0088] Embodiment 3: the preparation of 3# reaction solution

[0089] First, replace the 500L autoclave with ammonia gas three times, lower the temperature in the reactor to -20°C, add liquid ammonia (144.5Kg, 8500mol), start stirring, and feed acetylene (16800L, 750mol) at a concentration of 20wt%. Zinc acetate aqueous solution 8.7g, then adding concentration is 50wt% potassium hydroxide aqueous solution (1008g, the potassium hydroxide consumption as solute is 3mol% of acetone), be warming up to 10 ℃ and add acetone (17.4Kg, 300mol), control The acetone addition rate is about 1h, and the feed is completed; the reaction temperature is 10°C, and after 2 hours of reaction, 5Kg of ammonium sulfate aqueous solution with a concentration of 10wt% is added for neutralization to obtain 3-butyn-2-ol containing 2-methyl-3- #Reaction solution, and take a sample to detect the reaction solution by GC.

[0090] The composition of 3# reaction solution: the content of inorganic salt is 2.17w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com