Method for baking lithium ion battery or battery pole piece in tunnel mode

A technology for lithium-ion batteries and battery pole pieces, which is applied in the direction of drying solid materials by combining methods, drying, and drying solid materials, etc., which can solve the problems of shortening baking time and achieve shortened water removal time and good water removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

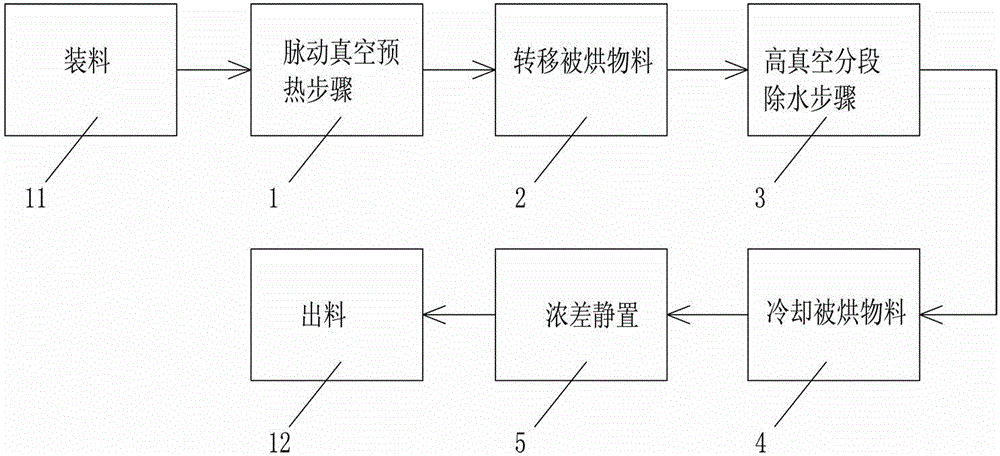

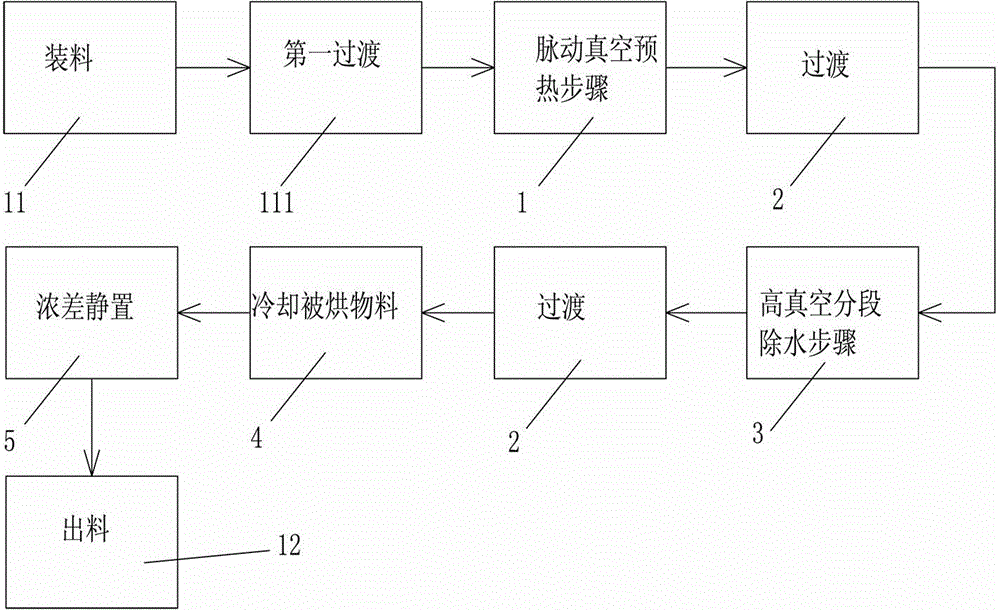

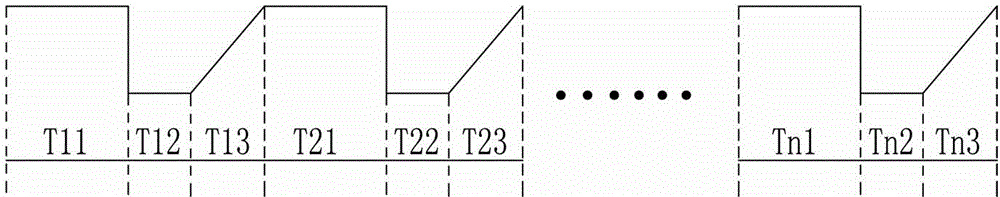

[0022] See figure 1 , figure 1 Disclosed is a method for tunnel-type baking of lithium-ion batteries or battery pole pieces, including a continuously working charging step 11, a pulsating vacuum preheating step 1, a high-vacuum segmental dehydration step 2, a rapid cooling step 3, a concentrated Differential static step 4 and discharging 12 steps, etc., the charging step 11, pulsating vacuum preheating step 1, high vacuum segmental water removal step 2, rapid cooling step 3, concentration difference static step 4 and discharging step 12. There are switchable doors at the front and back of the corresponding working boxes, and they are connected in sequence to form a tunnel structure. Each of the working boxes is independently sealed when working. When the processed lithium-ion battery or battery pole When the sheet enters the next working box from the previous working box, the door between the two adjacent outer boxes is opened under the condition that the pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com