Method for cleaning para-position aramid fiber strand

A para-aramid fiber and tow technology, applied in the field of man-made fiber preparation, can solve the problems of production capacity impact and contact time extension, and achieve the effect of not affecting the spinning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The cleaning method of para-aramid fiber tow provided by the invention comprises the following steps:

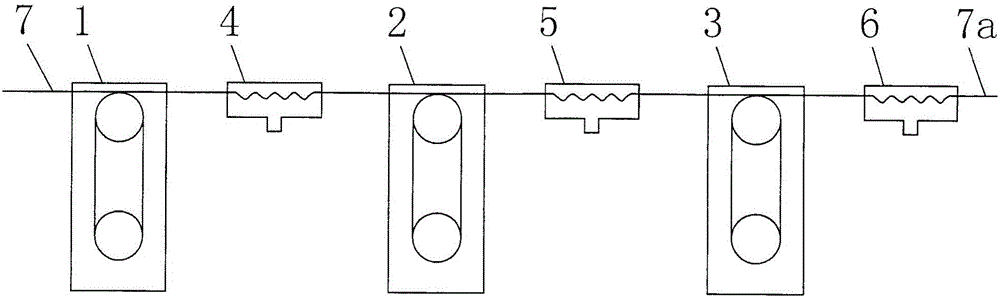

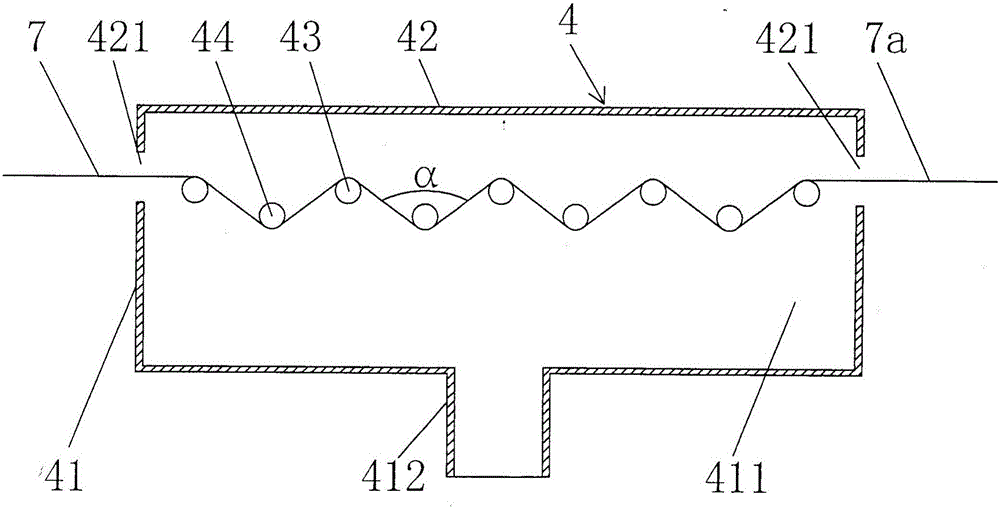

[0027] A) Equipped with a cleaning and dehydration device, please refer to the structure of the cleaning and dehydration device figure 1 , including washing roller 1, lye washing roller 2, dilute lye washing roller 3, first dehydrator 4, second dehydrator 5 and third dehydrator 6, water washing roller 1, lye washing roller 2 and dilute lye The washing roller 3 is arranged on the frame (not shown) in rotation in a state distributed from left to right, and the first dehydrator 4 is arranged at a position corresponding to the water washing roller 1 and the lye washing roller 2 On the frame, the second dehydrator 5 is arranged on the frame corresponding to the position between the lye washing roller 2 and the dilute lye washing roller 3, and the 3rd dehydrator 6 is arranged on the frame corresponding to the dilute lye washing roller 3. The position on the right is set on...

Embodiment 2

[0032] Only change the root number of one group of upper dewatering rollers 43 into 4 in step A), change the root number of one group of lower dewatering rollers 44 into 3, and change one group of upper and lower dewatering rollers 43,44 change the diameter of the para-aramid fiber tow 7 to 1650dtex in step B), change the washing time to 6S, change the mass % concentration of concentrated sulfuric acid to 99.8%, and change the heating Change the temperature to 78°C, change the mass % specific concentration of the spinning solution to 20%, change the width of the air layer to 12mm, and change the specific logarithmic concentration of the poly-p-phenylene terephthalamide resin solution to 6dl Change the spinning speed of the spinning box to 800m / min; Change the mass % ratio concentration of the lye in step C) to 0.8%, change the time of lye washing to 6S; change the step D) to The mass % specific concentration of the dilute lye is changed to 0.02%, the washing time of the dilute...

Embodiment 3

[0034] Only change the root number of one group of upper dewatering rollers 43 into 9 in step A), change the root number of one group of lower dewatering rollers 44 into 8, and change one group of upper and lower dewatering rollers 43,44 change the diameter of the para-aramid fiber tow 7 to 3300dtex in step B), change the washing time to 1.5S, change the mass % ratio concentration of concentrated sulfuric acid to 100.1%, change the added Change the temperature to 85°C, change the mass % specific concentration of the spinning solution to 19.5%, change the width of the air layer to 8mm, and change the specific logarithmic concentration of the poly-p-phenylene terephthalamide resin solution to 5dl / g; Change the spinning speed of spinning box into 600m / min; Change the mass % ratio concentration of the lye in step C) into 2%, change the time of lye washing into 1.5S; Change step D ) is changed to 0.03% by mass % of the dilute lye, the washing time of the dilute lye is changed to 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com