Solvent dewatering device

A solvent and water wheel technology, applied in the field of separation, can solve the problems of difficult to pass through the permeable membrane, poor solvent removal effect, etc., and achieve the effects of reduced distance, good water removal effect, and fast water removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

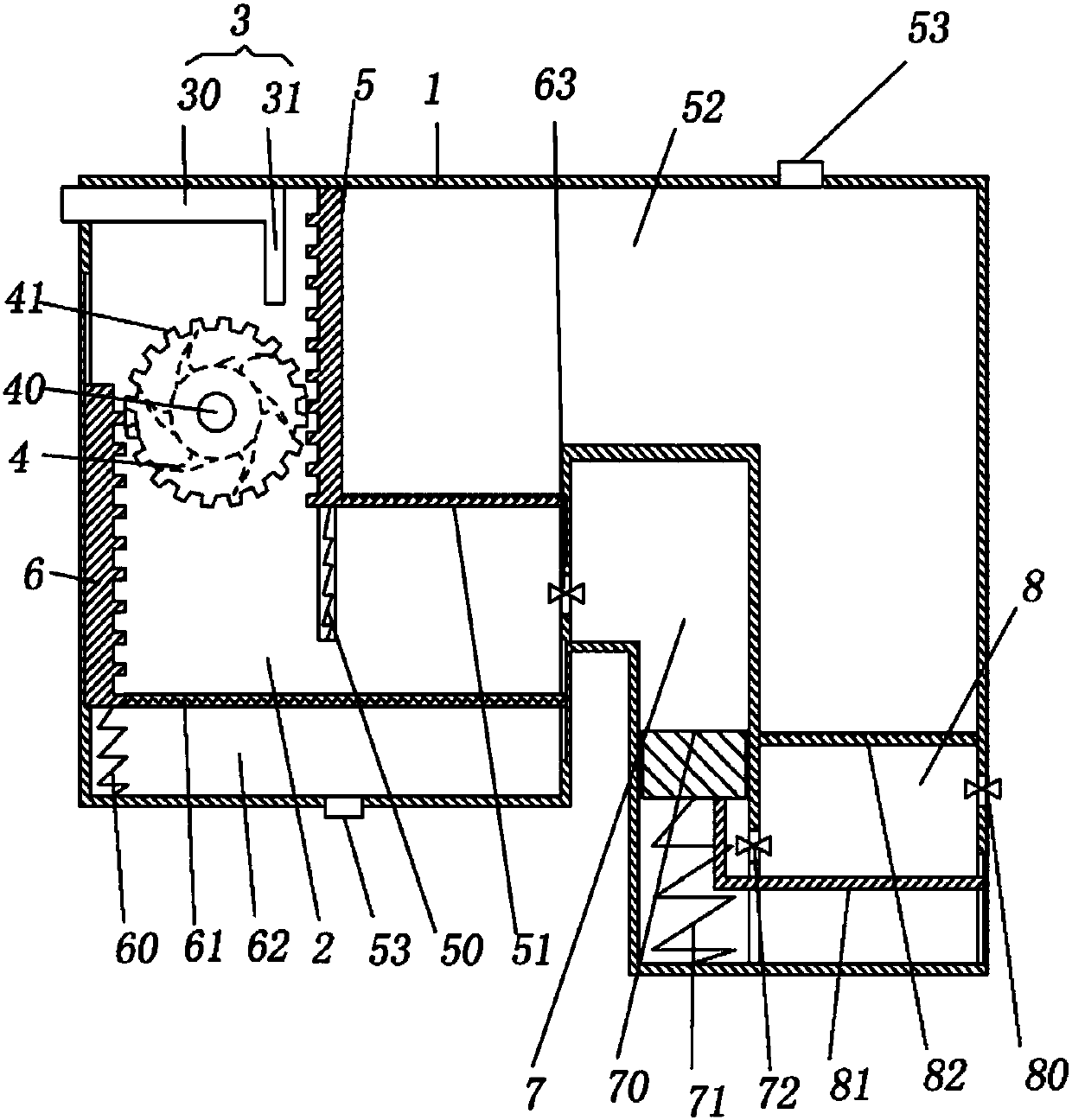

[0020] The reference signs in the accompanying drawings of the description include: tank shell 1, primary filter chamber 2, liquid inlet pipe 3, horizontal pipe 30, vertical pipe 31, water wheel 4, rotating shaft 40, gear 41, upper rack 5, reset member One 50, permeable membrane one 51, vacuum chamber one 52, vacuum pump interface 53, lower rack 6, reset piece two 60, permeable membrane two 61, vacuum chamber two 62, opening one 63, transition chamber 7, piston 70, reset piece Three 71, opening two 72, refilter chamber 8, opening three 80, support plate 81, permeable membrane three 82.

[0021] The embodiment is basically as attached figure 1 Shown: a solvent dehydration device, including a casing 1, and a primary filtration chamber 2, a transition chamber 7 and a refiltration chamber 8 are arranged in the casing 1.

[0022] The primary filter chamber 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com