Cable drying and dewatering device

A cable and drying technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of damage to the spark machine, limited width, etc., and achieve the effects of preventing damage, increasing cleanliness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

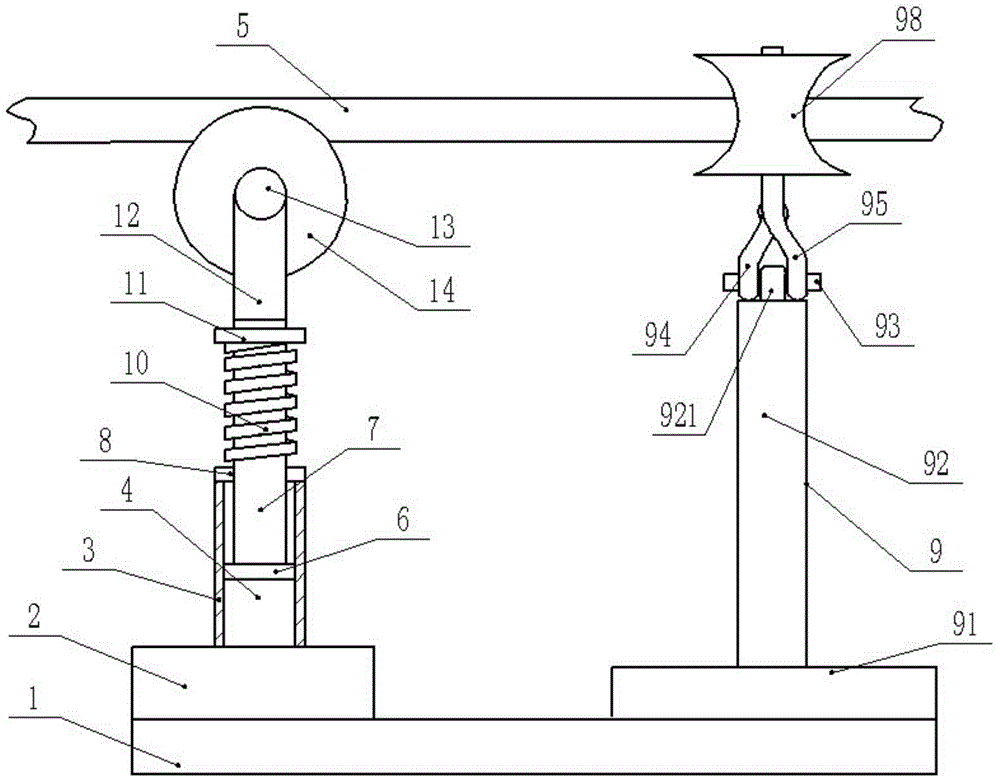

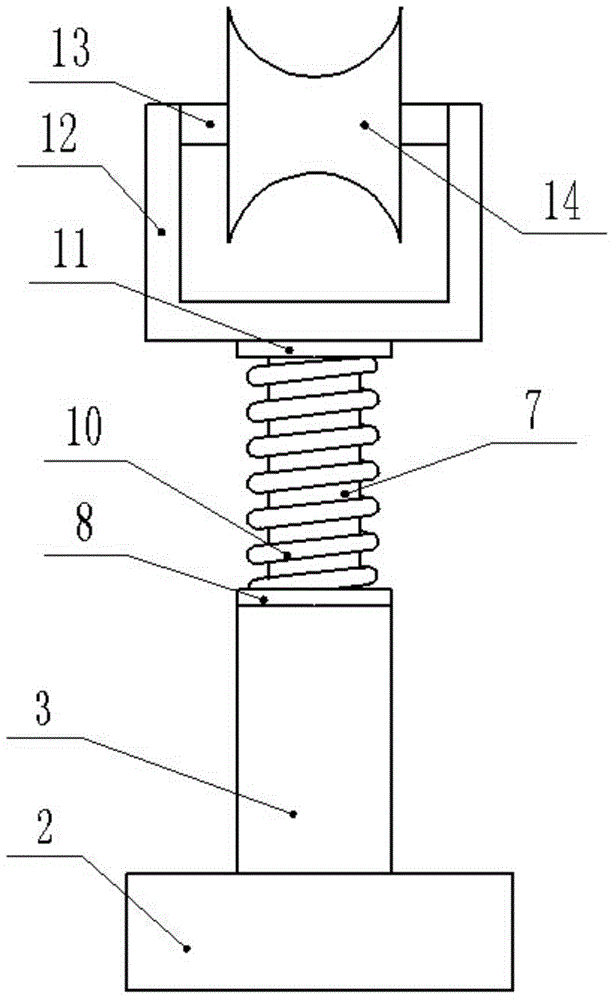

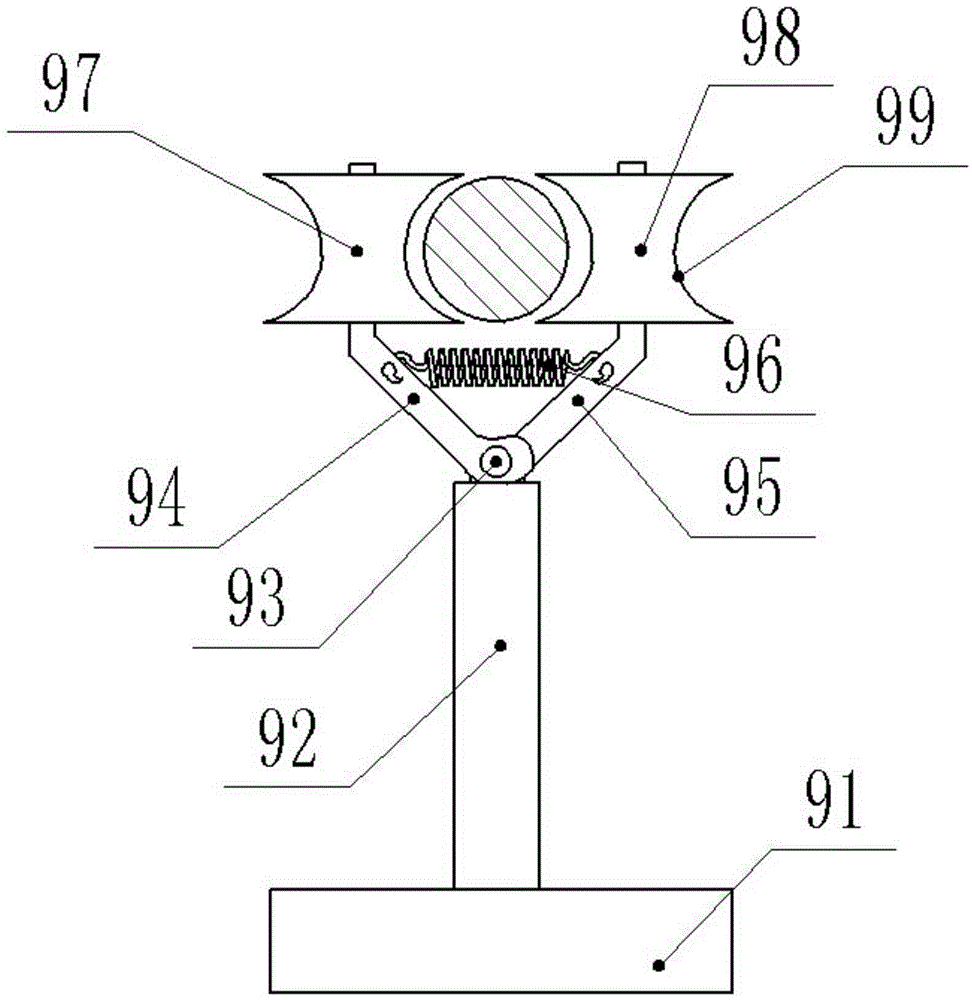

[0015] see Figure 1-3 , a cable drying and water removal device, comprising a base plate 1, a cable 5, and a water removal device 9, the upper left side of the base plate 1 is fixedly connected to a cable support mechanism by bolts, and the cable support mechanism is provided with a support base 2, a first Remove the water wheel 14 and the spring 10, the support base 2 is fixed on the left upper end of the base plate 1 by bolts, the upper end of the support base 2 is vertically provided with a sliding sleeve 3, and the sliding sleeve 3 is provided with a cylindrical sliding chamber 4, the sliding sleeve The upper end of 3 is provided with annular lower retaining spring plate 8, and wherein, the shaft center of the first water removal wheel 14 is provided with rotating shaft 13, and the first water removal wheel 14 is made of water-absorbent cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com