Breathing machine sampling pipe water removing method and device

A technology for sampling tubes and ventilators, which is applied in the field of water removal for ventilator sampling tubes, to achieve obvious effects of water removal, ensure accuracy, and use at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment:

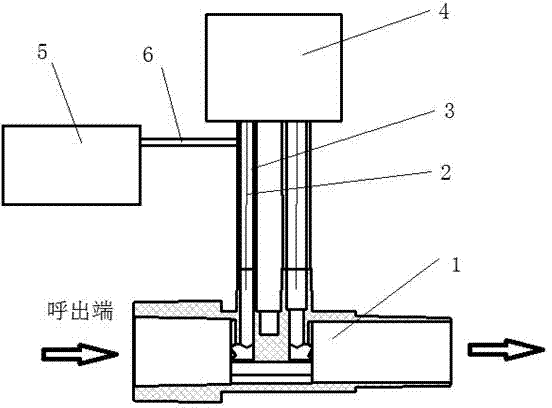

[0020] see figure 1 In the ventilator, an airflow pipe 1 through which breathing gas circulates is provided with two collection pipes 2 connected thereto, and the two pipes 2 are separated by a certain distance to collect the air pressure at two places corresponding to the airflow pipe 1 to the sensor 4. An air blowing tube 6 is arranged on the collecting tube 2 closest to the respiratory end of the air flow tube 1, and blows air to the collecting tube 2 through the blowing tube 6 with a corresponding blowing device.

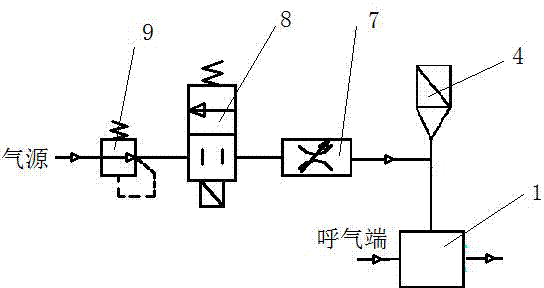

[0021] Such as figure 2 , the corresponding blowing device comprises blowing pipe 6 and blowing unit 5, and blowing unit 5 comprises decompression valve 9, the electromagnetic valve 8 and the flow regulating valve 7 of control blowing pipe 6 clearance, decompression valve 9, solenoid valve 8 and The flow regulating valve 7 is sequentially arranged on the air blowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com