Rapid drying method for lithium ion battery cell

A lithium-ion battery, rapid drying technology, applied in the direction of drying solid materials, method combination to dry solid materials, drying, etc., can solve the problems of long baking time of batteries, waste of energy and time, and occupying more ovens, etc., to achieve The effect of shortening the production cycle, saving equipment and energy costs, and fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

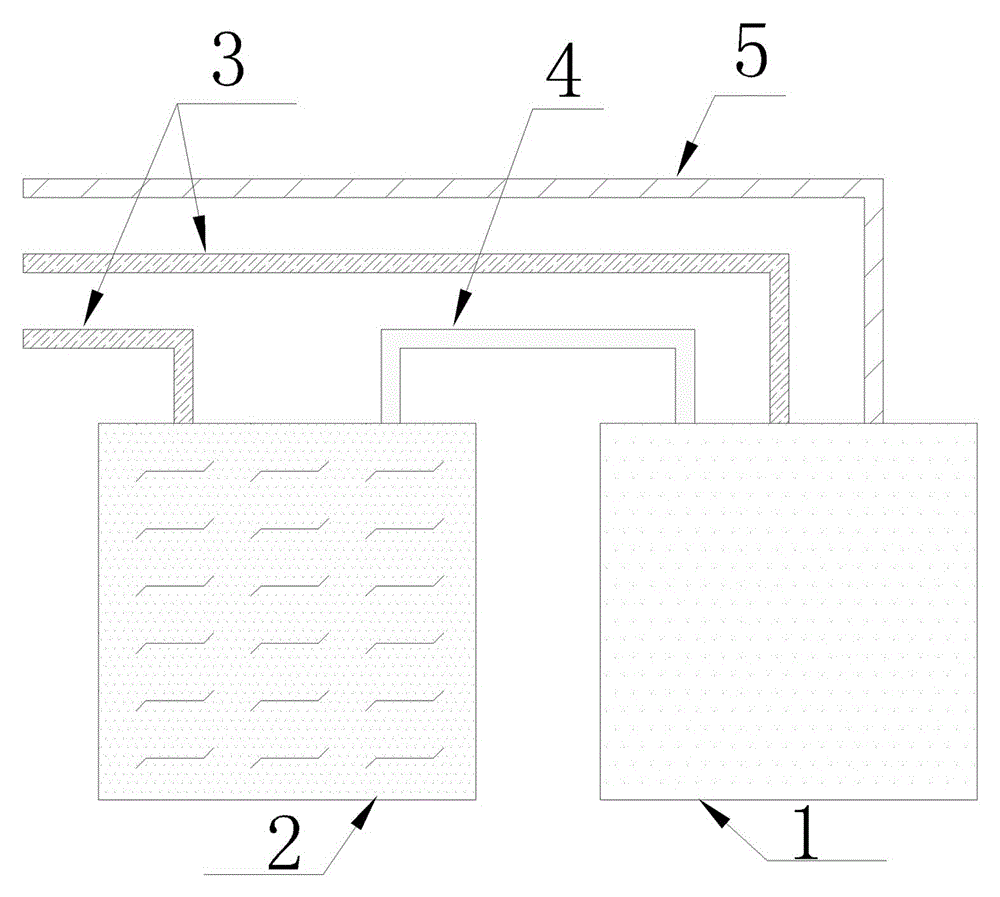

Image

Examples

Embodiment 1

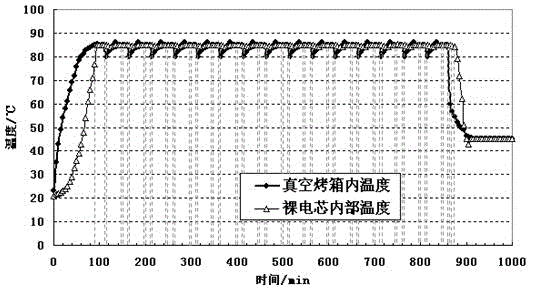

[0028] Baking samples of 18650-1600mAh-3.2V steel shell cylindrical lithium-ion battery cells.

[0029] 1. First put the bare cell sample into a vacuum oven, set the temperature of the vacuum oven to 85°C, the oven reaches the set temperature in about 1.5 hours at room temperature, and bake the bare cell at 85±5°C for 20 minutes;

[0030] 2. Then evacuate until the vacuum degree of the vacuum oven is below -0.095Mpa, it takes about 5 minutes to evacuate, and bake at 85±5°C for 30 minutes;

[0031] 3. Finally, fill the vacuum oven with high-temperature dry nitrogen at 85±5°C until the vacuum degree of the vacuum oven is above -0.01MPa. It takes about 5 minutes to inflate, and bake at 85±5°C for 10 minutes;

[0032] 4. Cycle ②~③ steps 15 times;

[0033] 5. Turn off the heating part of the vacuum oven, evacuate until the vacuum degree of the vacuum oven is below -0.08Mpa, and it takes about 5 minutes to pump air, and then fill it with dry nitrogen at room temperature until the v...

Embodiment 2

[0036] Carry out 09140200 type polymer lithium-ion battery cell sample baking.

[0037] 1. First put the bare cell sample into a vacuum oven, set the temperature of the vacuum oven to 85°C, the oven reaches the set temperature in about 1.5 hours at room temperature, and bake the bare cell at 85±5°C for 20 minutes;

[0038] 2. Then evacuate until the vacuum degree of the vacuum oven is below -0.095Mpa, it takes about 5 minutes to evacuate, and bake at 85±5°C for 20 minutes;

[0039] 3. Finally, fill the vacuum oven with high-temperature dry nitrogen at 85±5°C until the vacuum degree of the vacuum oven is above -0.01MPa. It takes about 5 minutes to inflate, and bake at 85±5°C for 5 minutes;

[0040] 4. Cycle ②~③ steps 10 times.

[0041] 5. Turn off the heating part of the vacuum oven, evacuate until the vacuum degree of the vacuum oven is below -0.08Mpa, and it takes about 5 minutes to pump air, and then fill it with dry nitrogen at room temperature until the vacuum degree of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com