Method and device for performing refined separation on high-purity yellow phosphorous

A separation device and technology for yellow phosphorus, applied in chemical instruments and methods, fractionation, phosphorus compounds, etc., can solve the problems of inability to carry out industrial application, low efficiency, etc., and achieve the characteristics of changing relative volatility, uniform heating and high separation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

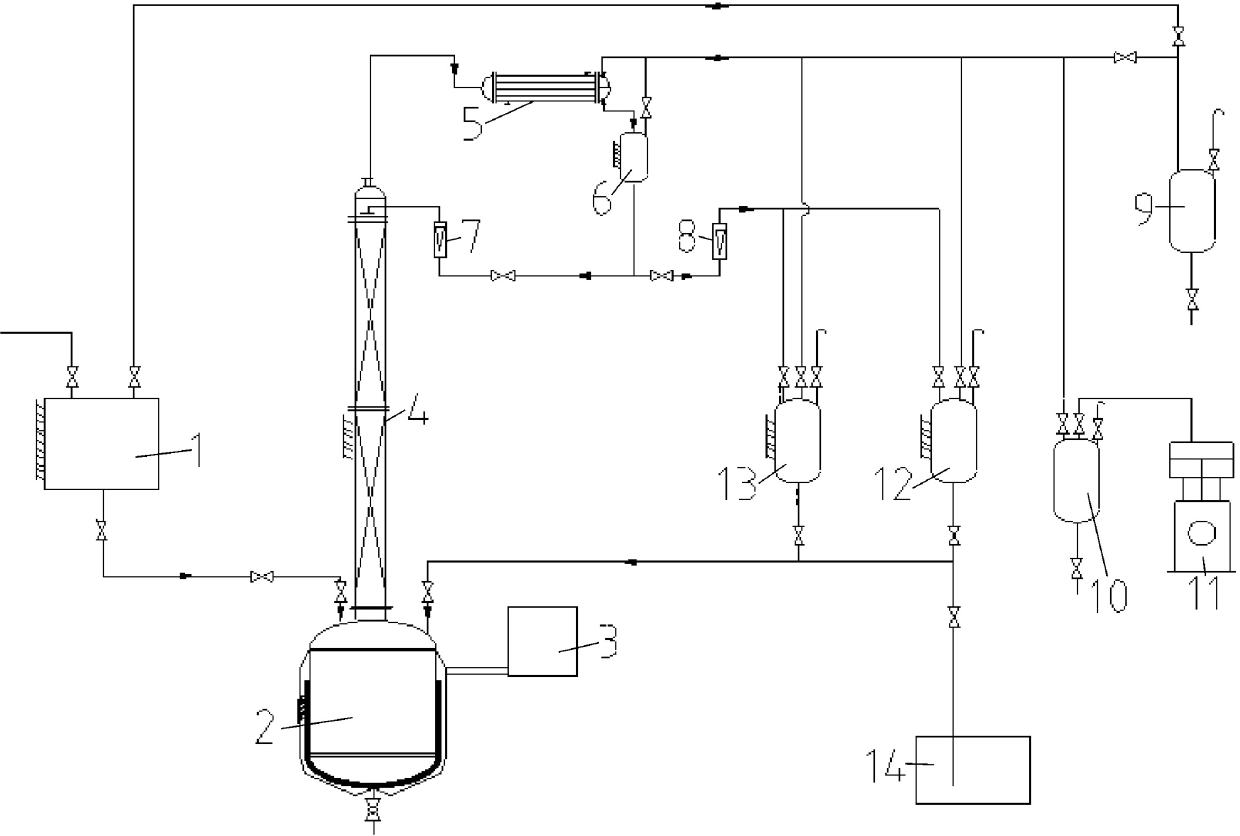

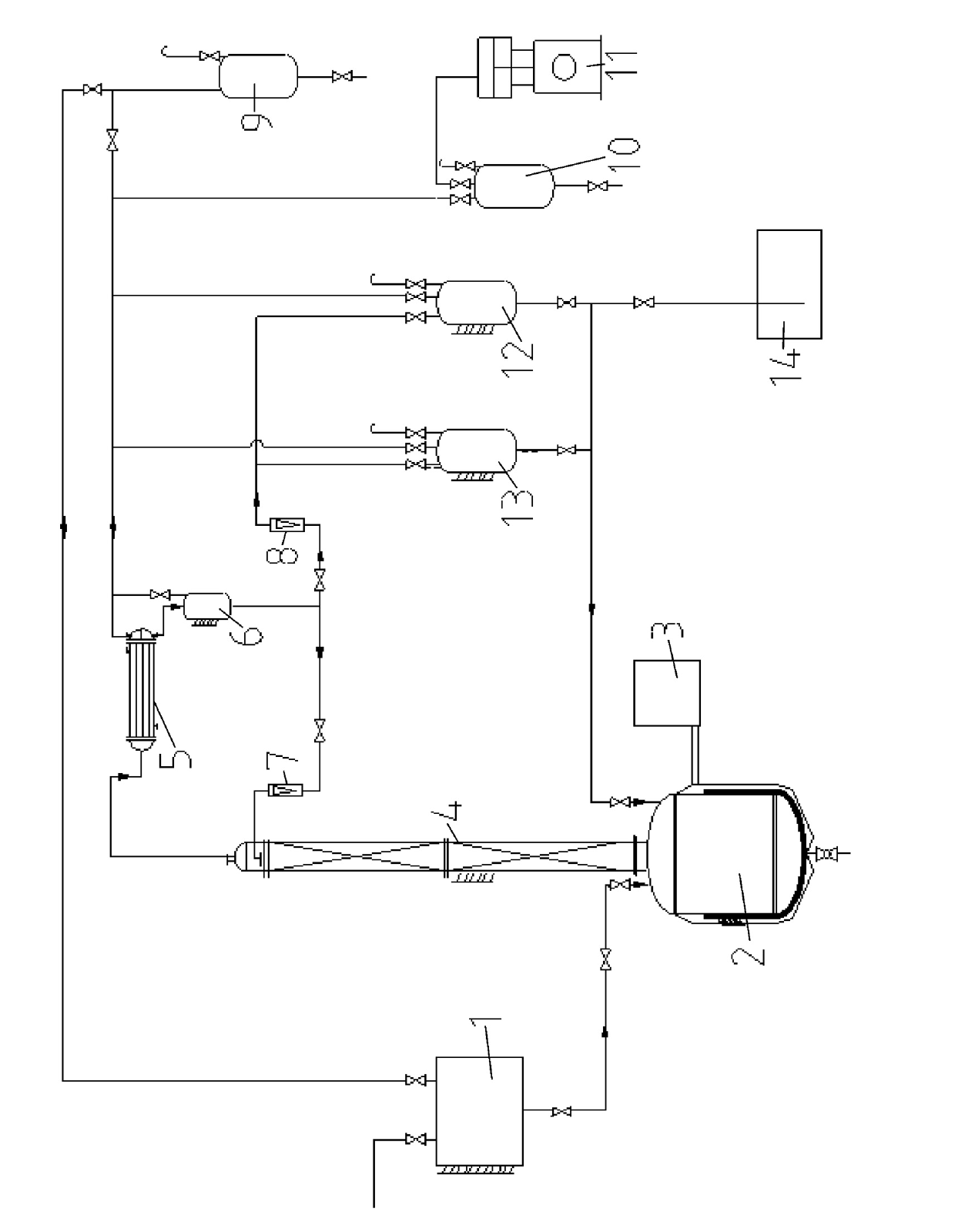

[0026] Such as figure 1 Among them, a refining and separating device for high-purity yellow phosphorus, the raw material storage tank 1 is connected to the tower kettle 2, the rectifying tower 4 is located above the tower kettle 2, one end of the condenser 5 is connected to the top of the rectifying tower 4, and the other end is connected to the top of the rectifying tower 4. The reflux tank 6 is connected, the reflux tank 6 is connected with the top of the rectification tower 4 through the reflux flowmeter 7, the reflux tank 6 is connected with the front fraction tank 13 and the product tank 12 through the product flow meter 8, and the product tank 12 outlet pipeline is connected with the product collection Slot 14 connection;

[0027] The vacuum pump 11 is connected with the condenser 5, the reflux tank 6, the front fraction tank 13 and the product tank 12 through the surge tank 10;

[0028] The nitrogen tank 9 is connected with the raw material storage tank 1 , the condens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com