Method for degrading and recycling thermosetting epoxy resin material

A technology of epoxy resin and heat recovery, applied in plastic recycling, recycling technology, etc., can solve problems such as poor wettability, weakening chemical bonds, limiting catalyst diffusion and resin degradation, achieving less by-products, high degradation efficiency, and reduced degradation and recycling cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Mix zinc chloride with an aqueous acetic acid solution with a mass concentration of 90% acetic acid to prepare a 50ml reaction solution with a catalyst mass percentage of 40%;

[0032] (2) Add 0.5 g of the epoxy resin material synthesized in formula (1) to the reaction solution, and the epoxy resin material is immersed under the liquid surface of the reaction liquid and degraded at 100°C for 72 hours;

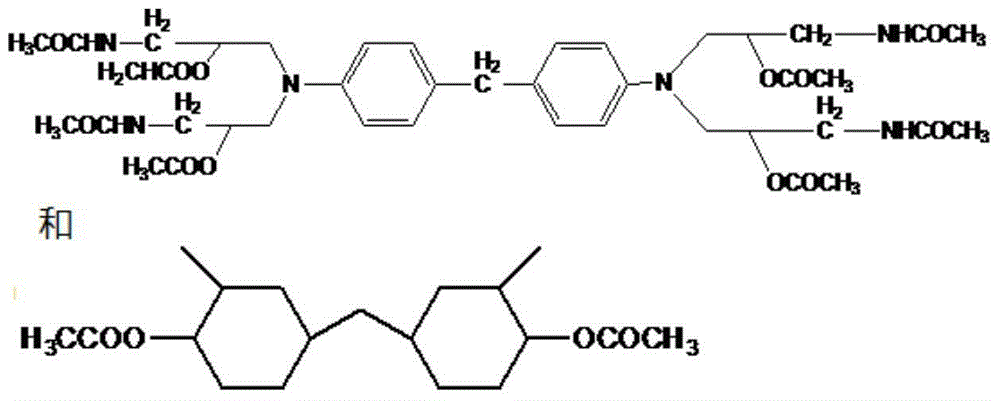

[0033] (3) After the reaction and cooling, add 1000ml of acetone to the degradation material and filter. The filtered solids are reinforcing fibers and catalysts, which are dried and sieved and recovered; the filtrate is evaporated to dryness to obtain resin degradation products, which are degraded by analysis The structural formula of the product is:

[0034]

Embodiment 2

[0036] (1) Mix zinc bromide and an aqueous solution of acetic acid with a mass concentration of 95% acetic acid to form a 50ml reaction solution with a catalyst mass percentage of 30%;

[0037] (2) Add 1.0g of the epoxy resin material synthesized in formula (2) to the reaction solution, the epoxy resin material is immersed under the liquid surface of the reaction liquid and degraded at 120°C for 48 hours;

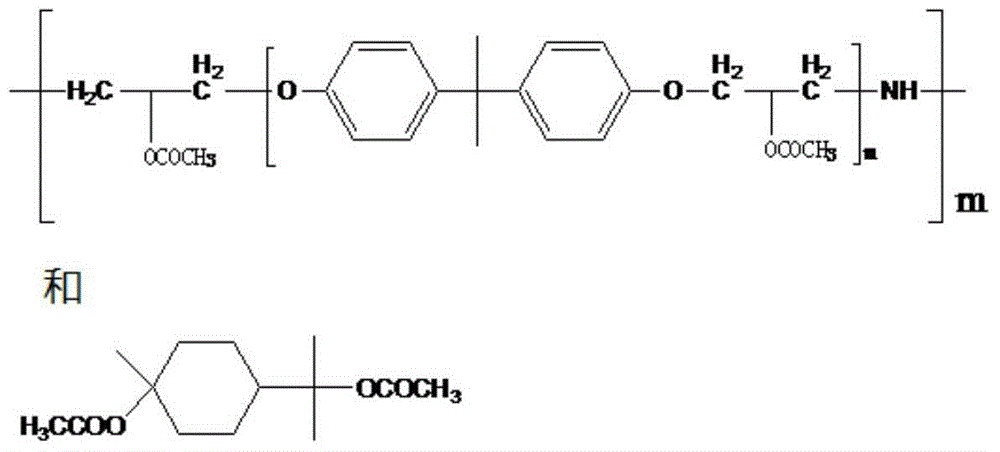

[0038] (3) After the reaction and cooling, add 5000ml of tetrahydrofuran to the degraded material and filter. The filtered solids are reinforcing fibers and catalysts, which are recovered after drying and screening; the filtrate is evaporated to dryness to obtain resin degradation products, which are degraded by analysis The structural formula of the product is:

[0039]

[0040] Among them: m=1-5, n=2-4

Embodiment 3

[0042] (1) Mix aluminum chloride with an acetic acid aqueous solution with a mass concentration of 99% acetic acid to prepare a 50ml reaction solution with a catalyst mass percentage of 10%;

[0043] (2) Add 1.5g of the epoxy resin material synthesized in formula (3) to the reaction solution, the epoxy resin material is immersed under the liquid surface of the reaction liquid and degraded at 140°C for 36 hours;

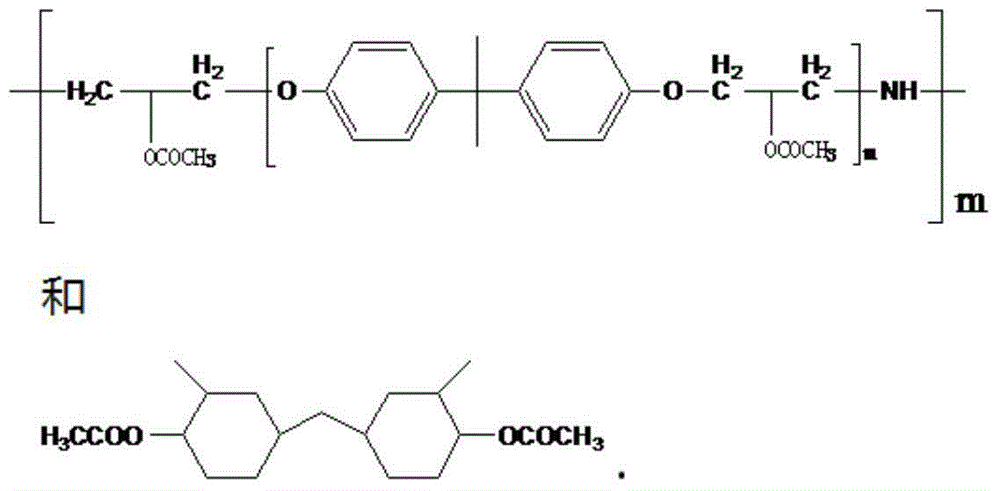

[0044] (3) After the reaction and cooling, add 500ml of chloroform to the degradation material and filter. The filtered solids are reinforcing fibers and catalysts, which are dried and sieved and recovered; the filtrate is evaporated to dryness to obtain resin degradation products, which are degraded by analysis The structural formula of the product is:

[0045]

[0046] Among them: m=1-5, n=2-4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com