Process for treating waste pickling liquid of hydrochloric acid by negative-pressure external-circulation evaporation-concentrating crystallization method

A technology of pickling waste liquid and crystallization method, applied in heating water/sewage treatment and other directions, can solve the problems of increased investment, waste, poor sales, etc., and achieves reduced equipment corrosion, reduced hydrogen chloride leakage, and simple and easy operation. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

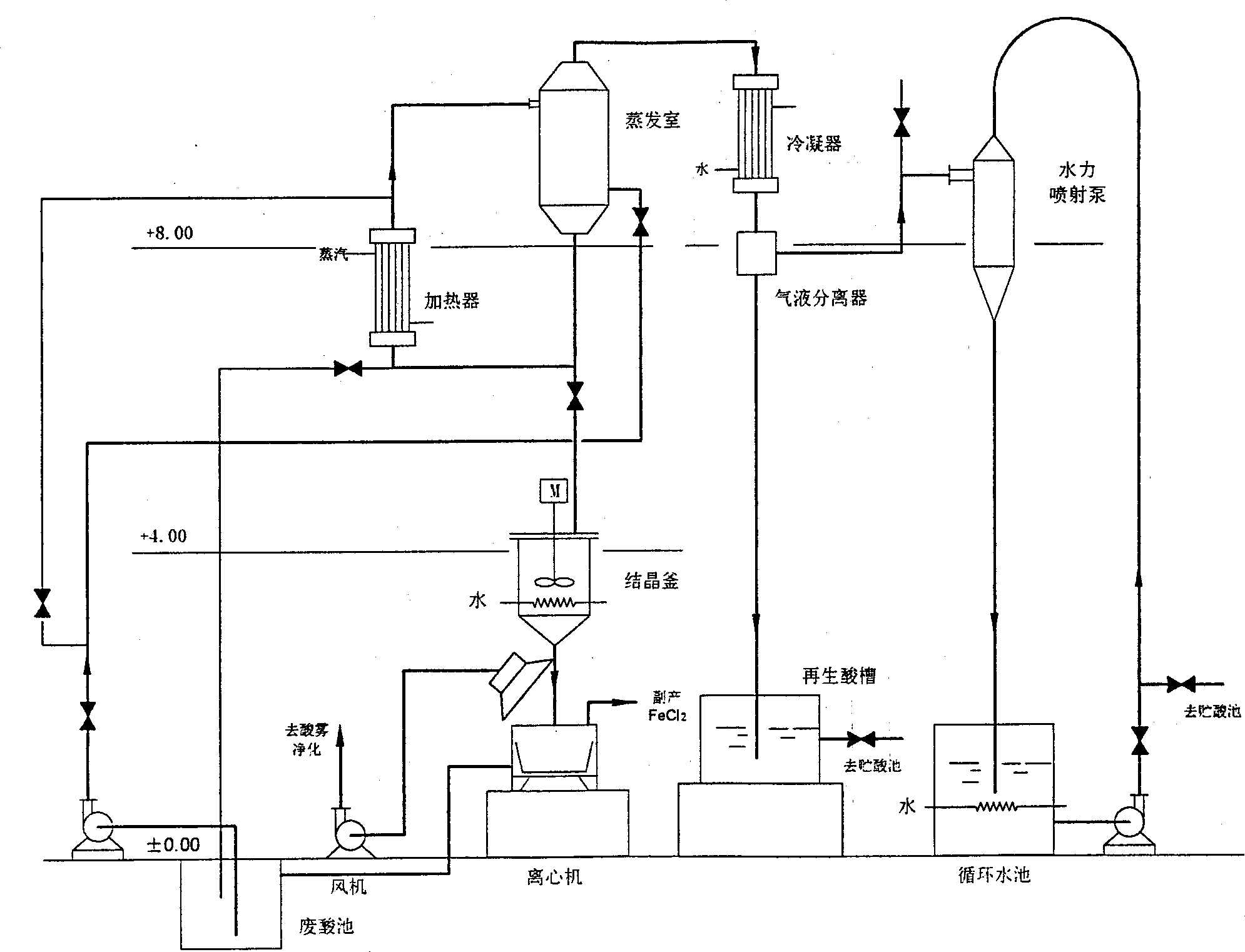

[0010] A specific embodiment of the present invention is shown in the attached drawings. It includes the following steps: first pump the waste acid liquid to the evaporation chamber, and when the feed liquid level is reached, turn on the hydraulic jet pump to make the system vacuum reach 600mmHg, and turn on The steam valve makes the heater start to heat and evaporate the waste acid liquid. The waste acid liquid circulates between the heater and the evaporation chamber for heating, evaporation and concentration. The HCl and water vapor vaporized from the evaporation chamber are condensed by the graphite condenser to recover dilute hydrochloric acid and enter the regeneration process. The acid tank overflows to the hydrochloric acid storage tank. The non-condensable gas and a small amount of HCl enter the hydraulic jet pump for cyclic absorption. When the HCl in the circulating tank reaches the working concentration requirement, it is pumped to the hydrochloric acid storage tank, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com