Coal flotation process automatic control system and method

An automatic control system, coal preparation technology, applied in flotation, solid separation and other directions, can solve problems such as high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

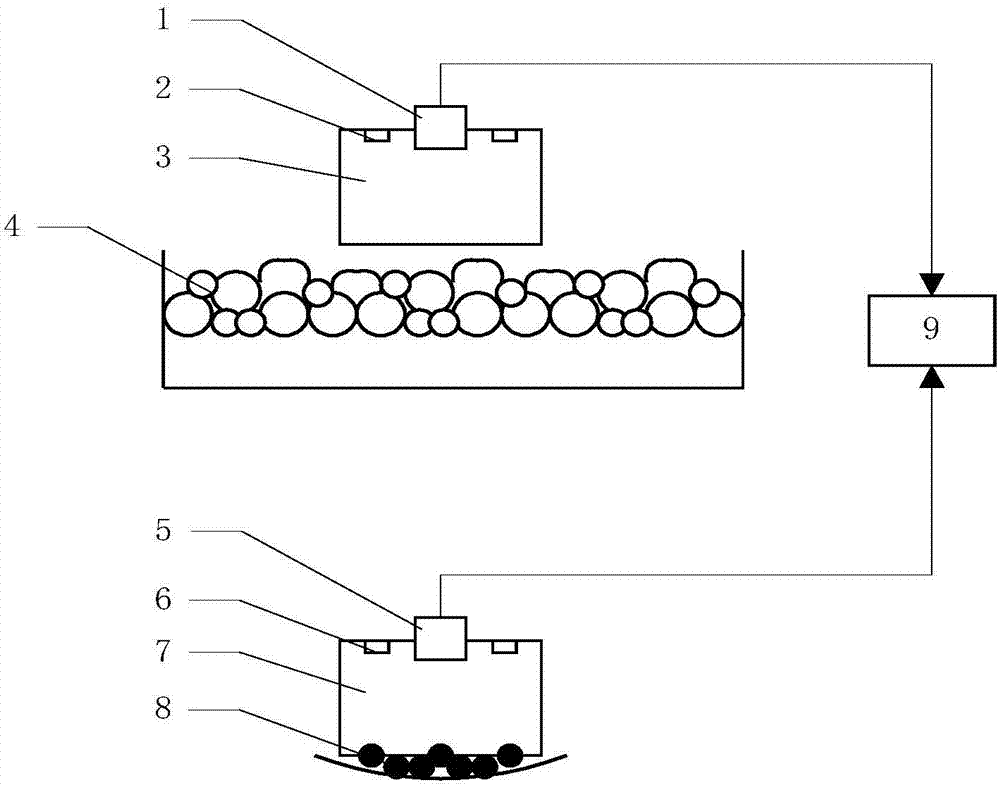

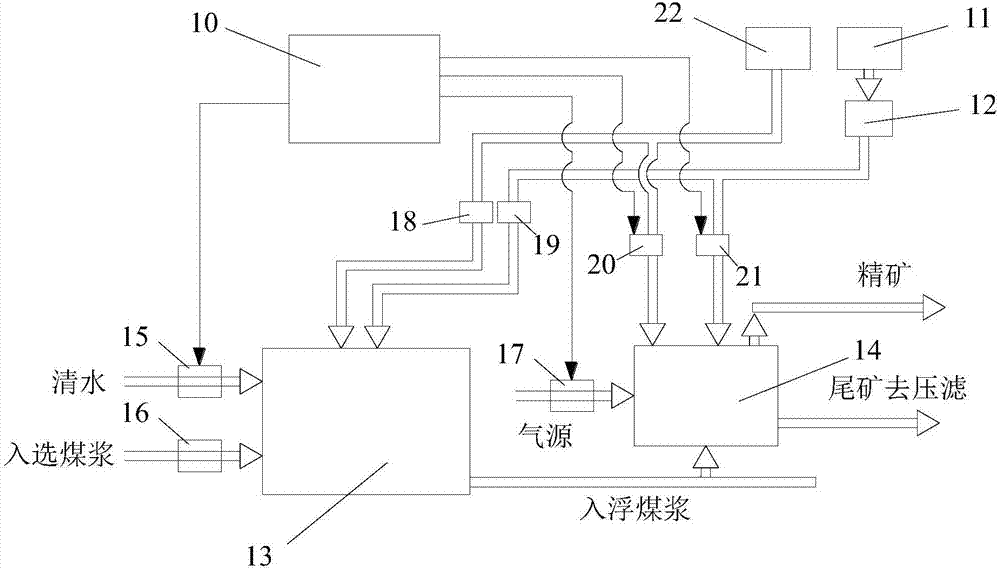

[0031] Embodiment 1: The flotation equipment is started to work, the selected coal slurry valve 16 on the selected coal slurry pipeline is opened, the input selected coal slurry enters the slurry preprocessor 13, and the collector storage tank 11 transports the collector into the colloid mill 12, pre-processed The treatment foaming agent dosing valve 18 and the pretreatment collector dosing valve 19 are manually determined and kept constant according to the concentration of the selected coal slurry. The foaming agent and the emulsified collector are mixed with the selected coal slurry evenly. Generate the floating coal slurry, the pulp preprocessor 13 transports the floating coal slurry into the flotation machine 14, and the flotation machine 14 starts the flotation operation. The flotation foam 4 enriched in clean coal is produced in the flotation chamber, and the flotation tailings 8 are sent to press filtration; the first camera 1 takes images of the flotation foam 4 enriche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com