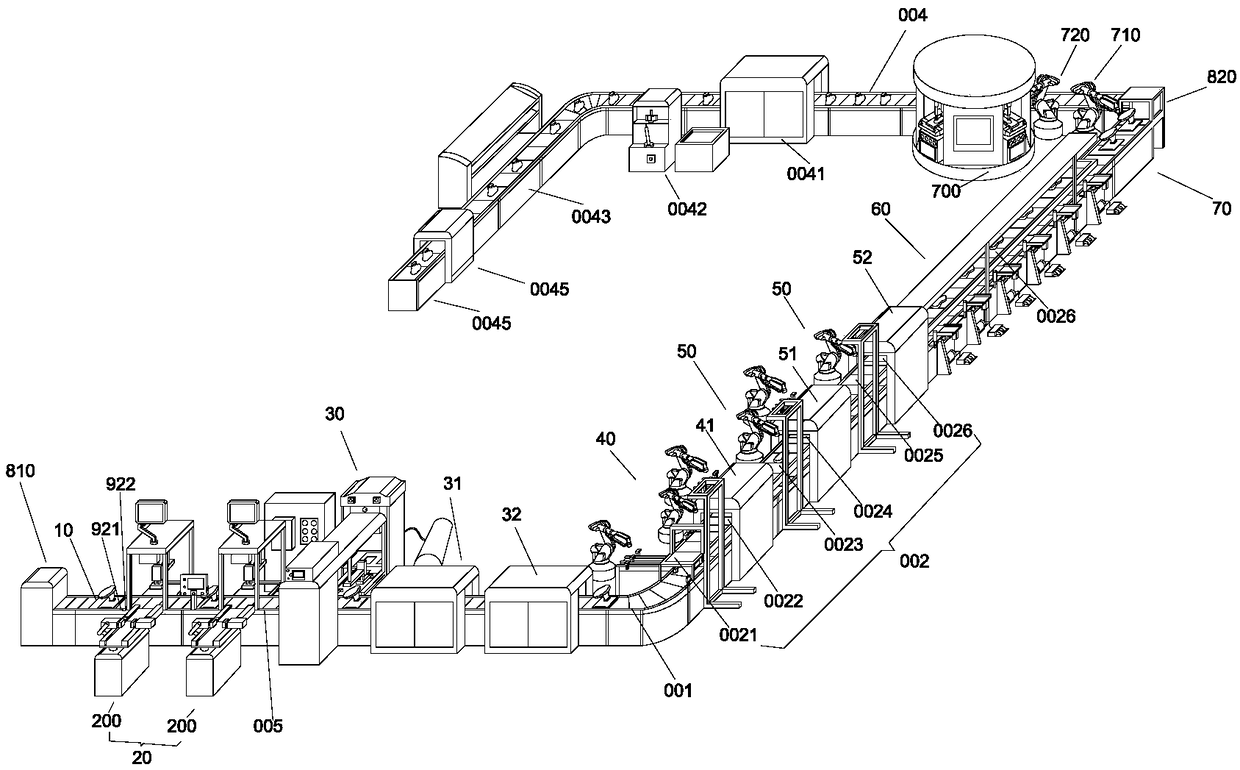

Automatic shoe production line and control method thereof

An automated production line and main control technology, applied in the direction of footwear, adhesive shoe parts, shoe-making machinery, etc., can solve problems such as uneven quality, human hazards, and rising labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0138] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

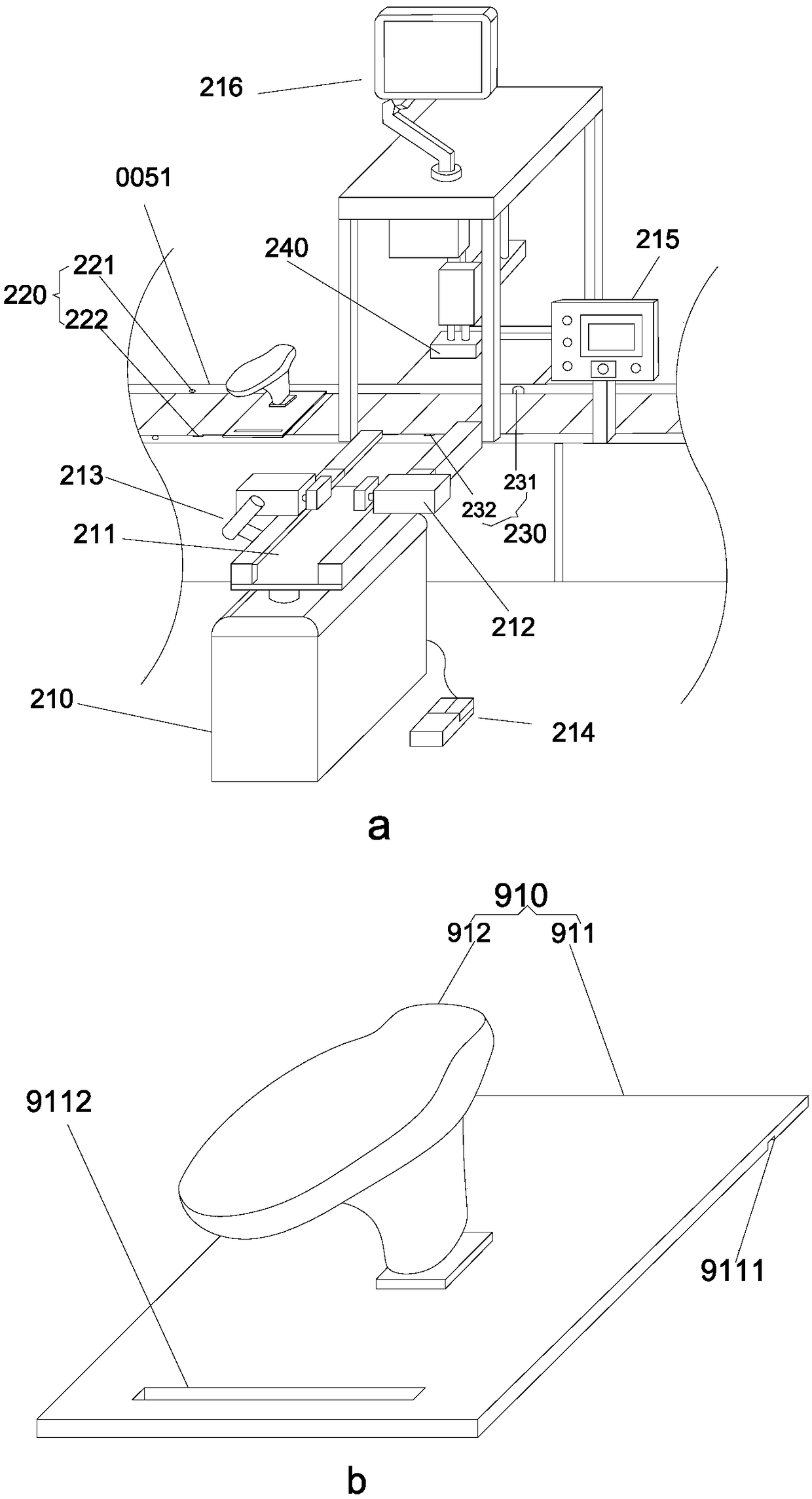

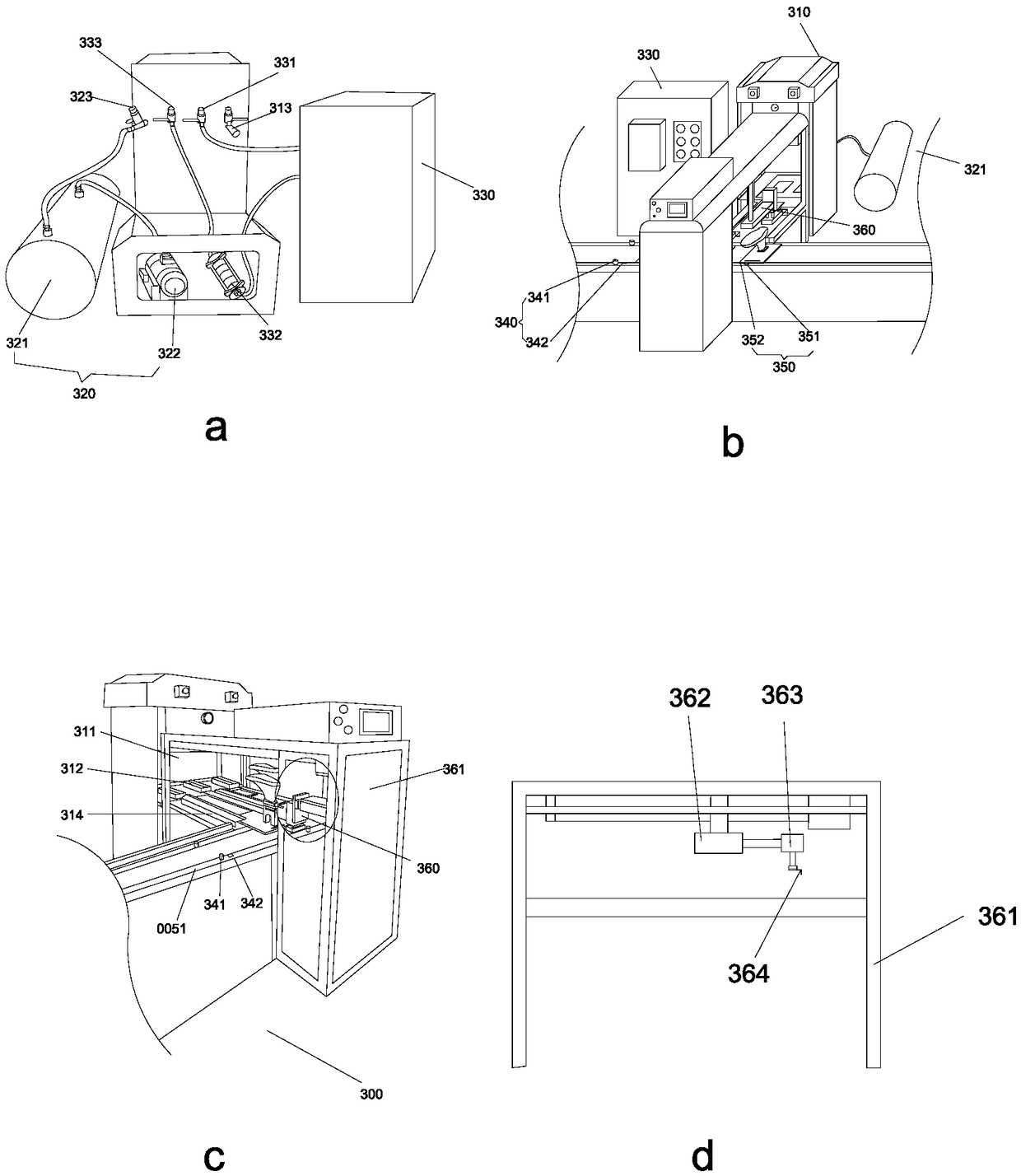

[0139]It should be pointed out in advance that in this embodiment, the detector is a photoelectric sensor, and the main conveyor belt 001 is a constant speed transmission. The shoe last 912 buckle of the shoe upper is inserted on the tooling board 911, and there are many ways for the shoe last 912 buckle to be inserted on the tooling board 911; Inserting part, such as latch 612, clamping block etc.; In addition, on the tooling plate 911, set corresponding jacks, draw-in slots etc. with the connecting part, and the shoe last 912 and tooling plate 911 can be installed according to this. In this embodiment, the last feeding limit device 220, the last feeding limit device 230, the steam and wet feed limit device 340, the steam and wet limit device 350, the brush treatment agent limit device 450, the glue brush feed limit Position device 540, brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com