A microwave-absorbing corrosion-resistant powder material and a preparation method thereof

A powder material, microwave absorption technology, applied in chemical instruments and methods, metal material coating technology, other chemical processes, etc. Effects of insufficient microwave absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

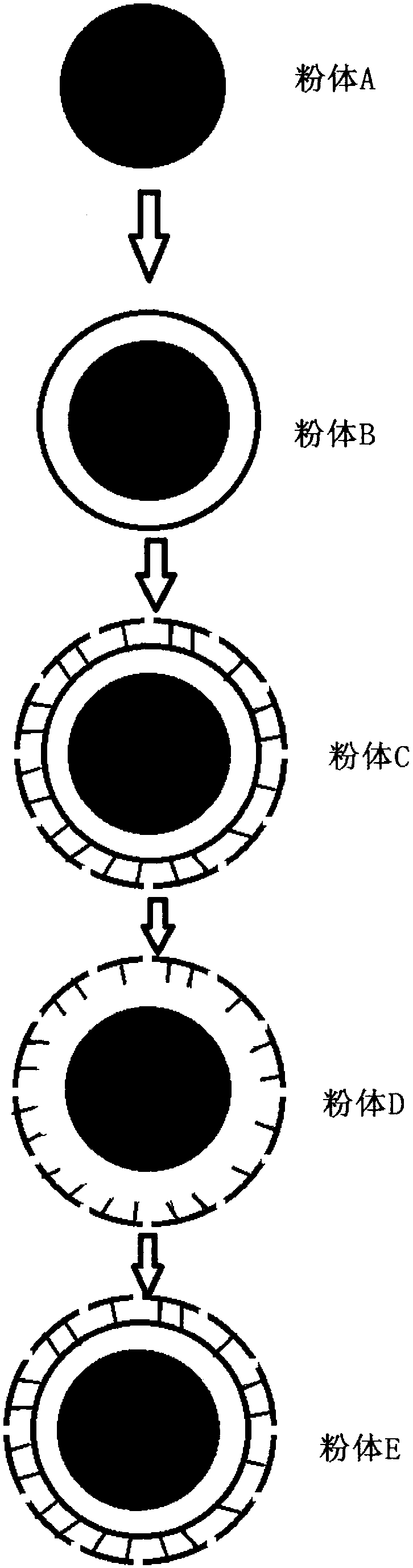

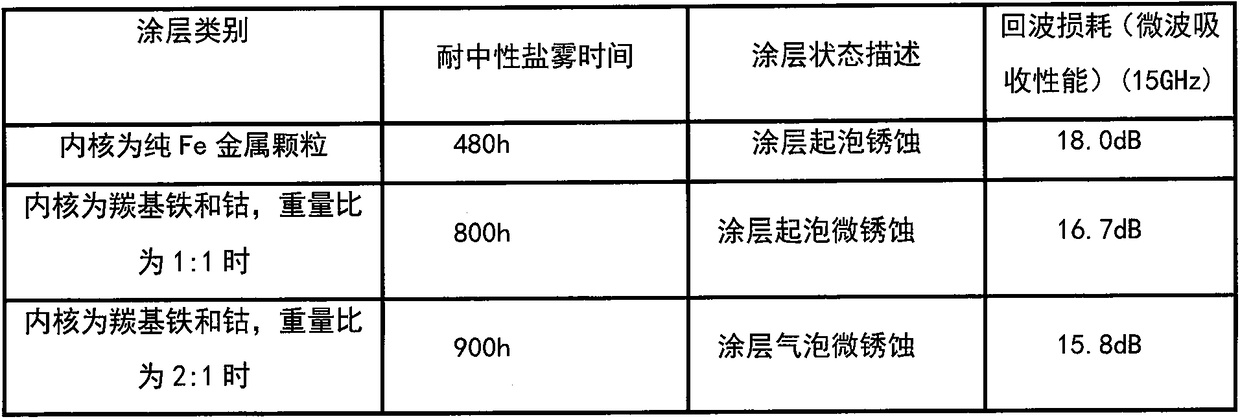

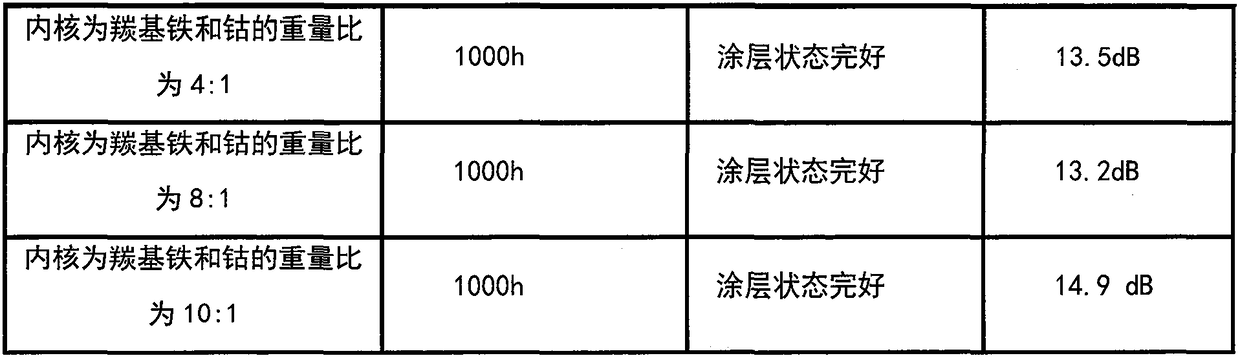

[0022] The microwave-absorbing corrosion-resistant powder material of the present application adopts carbonyl iron with a particle size of 1 micron: when the ratio of cobalt weight is 4:1, the specific preparation method adopted is:

[0023] The first step: preparing the inner core of the magnetic metal micropowder. First, disperse 10 g of magnetic metal micropowder (carbonyl iron: cobalt weight ratio = 4:1) with a particle size of about 1 micron in absolute ethanol and place it in a high-speed ball mill for processing. After grinding and dispersing for 5 hours, vacuum dry at 50°C for 3 hours, powder A was obtained.

[0024] The second step: the surface of the magnetic metal micropowder is coated with a polymer layer. Weigh 1.1g of the powder A obtained above and ultrasonically disperse it into 200ml of aqueous solution, and stir continuously for 30min, wherein the peripheral linear velocity of the stirring blade is 3-5 m / s, and then add 0.06g of surfactant dodecylbenzene So...

Embodiment 2

[0030] The microwave-absorbing corrosion-resistant powder material of the present application adopts carbonyl iron with a particle size of 0.6 microns: when the proportioning ratio of nickel oxyhydroxide=8:1, the specific preparation method adopted is:

[0031] The first step: preparing the inner core of the magnetic metal micropowder. First, disperse 10 g of magnetic metal micropowder (iron carbonyl: nickel oxyhydroxide weight ratio = 8:1) with a particle size of about 0.6 microns in absolute ethanol and place it in a high-speed ball mill for processing. After grinding and dispersing for 5 hours, vacuum dry at 50 ° C. After 3 hours, powder A was obtained.

[0032] The second step: the surface of the magnetic metal micropowder is coated with a polymer layer. Weigh 1.1g of the powder A obtained above and ultrasonically disperse it into 200ml of aqueous solution, and stir continuously for 30min, wherein the peripheral linear velocity of the stirring blade is 3-5 m / s, and then a...

Embodiment 3

[0038] The microwave-absorbing corrosion-resistant powder material of the present application adopts carbonyl iron with a particle size of 0.8 microns: when the proportioning ratio of nickel oxyhydroxide=6:1, the specific preparation method adopted is:

[0039] The first step: preparing the inner core of the magnetic metal micropowder. First, disperse 10 g of magnetic metal micropowder (carbonyl iron: nickel hydroxide weight ratio = 6:1) with a particle size of about 0.8 microns in absolute ethanol and place it in a high-speed ball mill for processing. After grinding and dispersing for 5 hours, vacuum dry at 50 ° C. After 3 hours, powder A was obtained.

[0040] The second step: the surface of the magnetic metal micropowder is coated with a polymer layer. Weigh 1.1g of the powder A obtained above and ultrasonically disperse it into 200ml of aqueous solution, and stir continuously for 30min, wherein the peripheral linear velocity of the stirring blade is 3-5 m / s, and then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com