Corrosion-resistant powder material capable of absorbing microwaves and preparation method thereof

A powder material and microwave-absorbing technology, which is applied in the direction of chemical instruments and methods, metal material coating technology, and other chemical processes, can solve the problems of insufficient microwave absorption capacity of microwave-absorbing coatings and deterioration of corrosion resistance. Effects of Insufficient Microwave Absorbing Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

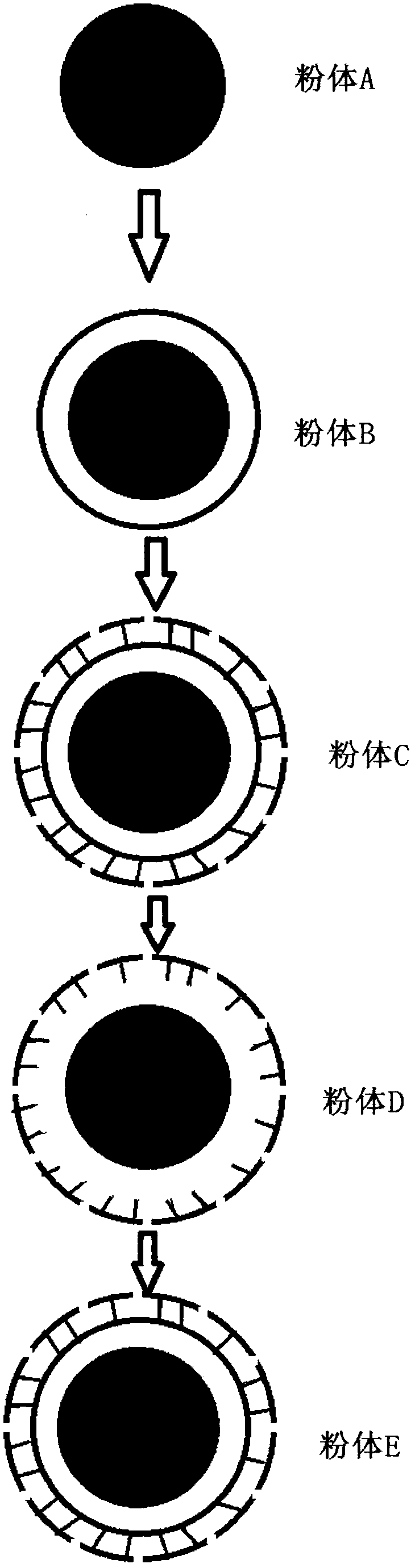

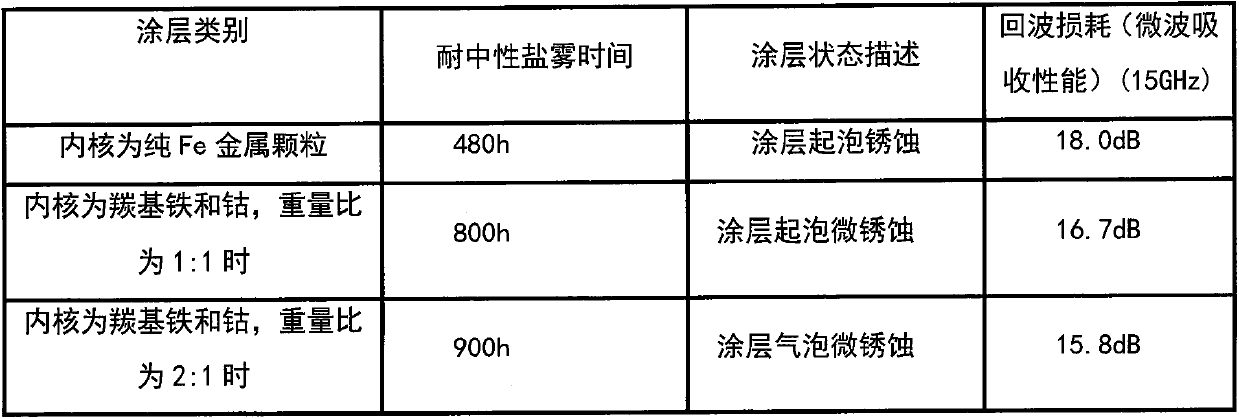

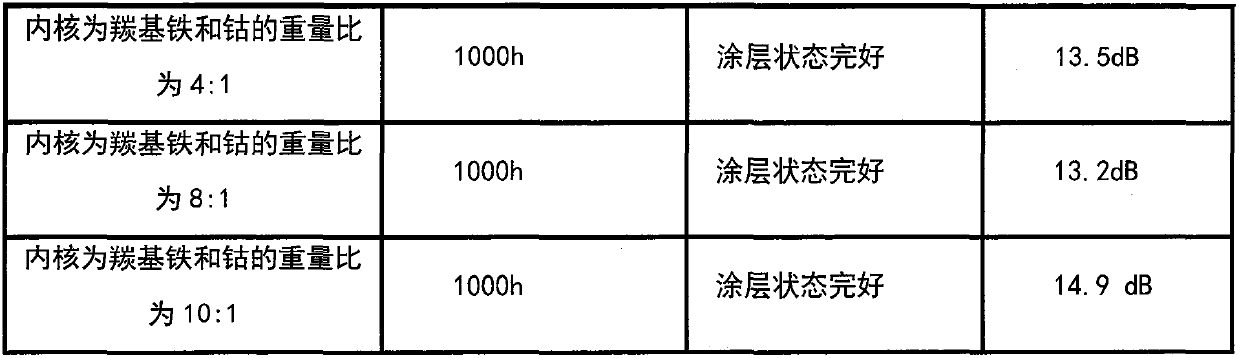

[0022] The microwave-absorbing corrosion-resistant powder material of the present application adopts carbonyl iron with a particle size of 1 micron: when the ratio of cobalt weight ratio=4:1, the specific preparation method adopted is:

[0023] The first step: preparing the inner core of the magnetic metal micropowder. First, 10 g of magnetic metal fine powder (carbonyl iron: cobalt weight ratio = 4: 1) with a particle size of about 1 micron is dispersed in absolute ethanol and placed in a high-speed ball mill for processing. After grinding and dispersing for 5 hours, vacuum-dry at 50 ° C for 3 hours, powder A was obtained.

[0024] The second step: the surface of the magnetic metal micropowder is coated with a polymer layer. Weigh 1.1g of the powder A obtained above and ultrasonically disperse it into 200ml of aqueous solution, and stir continuously for 30min, wherein the peripheral linear velocity of the stirring blade is 3-5 m / s, and then add 0.06g of surfactant dodecylben...

Embodiment 2

[0030] The microwave-absorbing corrosion-resistant powder material of the present application adopts carbonyl iron with a particle size of 0.6 microns: when the proportioning ratio of nickel oxyhydroxide=8:1, the specific preparation method adopted is:

[0031] The first step: preparing the inner core of the magnetic metal micropowder. First, disperse 10 g of magnetic metal micropowder (iron carbonyl: nickel oxyhydroxide weight ratio = 8:1) with a particle size of about 0.6 microns in absolute ethanol and place it in a high-speed ball mill for processing. After grinding and dispersing for 5 hours, vacuum dry at 50 ° C. After 3 hours, powder A was obtained.

[0032] The second step: the surface of the magnetic metal micropowder is coated with a polymer layer. Weigh 1.1g of the powder A obtained above and ultrasonically disperse it into 200ml of aqueous solution, and stir continuously for 30min, wherein the peripheral linear velocity of the stirring blade is 3-5 m / s, and then a...

Embodiment 3

[0038] The microwave-absorbing corrosion-resistant powder material of the present application adopts carbonyl iron with a particle size of 0.8 microns: when the proportioning ratio of nickel hydroxyl = 6: 1, the specific preparation method adopted is:

[0039] The first step: preparing the inner core of the magnetic metal micropowder. First, disperse 10 g of magnetic metal micropowder (carbonyl iron: nickel hydroxide weight ratio = 6:1) with a particle size of about 0.8 microns in absolute ethanol and place it in a high-speed ball mill for processing. After grinding and dispersing for 5 hours, vacuum dry at 50 ° C. After 3 hours, powder A was obtained.

[0040] The second step: the surface of the magnetic metal micropowder is coated with a polymer layer. Weigh 1.1g of the powder A obtained above and ultrasonically disperse it into 200ml of aqueous solution, and stir continuously for 30min, wherein the peripheral linear velocity of the stirring blade is 3-5 m / s, and then add 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com