Preparation method of super cotton-like polyester fiber by continuous polymerizing melt direct spinning

A cotton polyester fiber, melt direct spinning technology, applied in the direction of melt spinning, stretch spinning, fiber processing, etc., can solve the problems affecting the performance stability of polyester fibers, uneven dispersion of additives, uneven mixing, etc. , to achieve the effect of improving spinnability, improving product stability and reducing blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

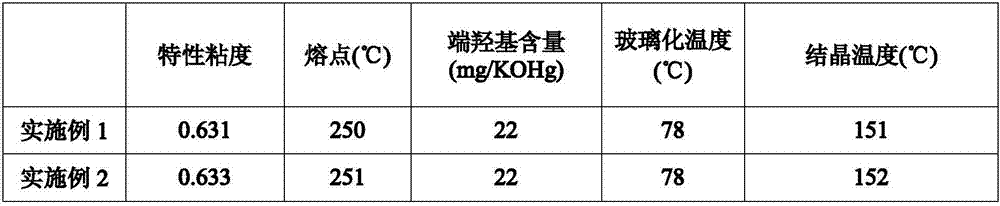

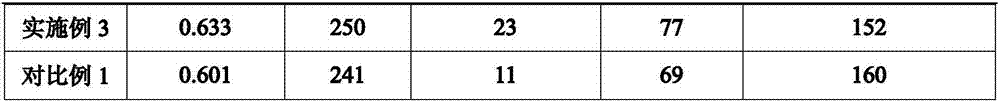

Examples

Embodiment 1

[0043] This embodiment provides a preparation method for continuous polymerization melt direct spinning super-cotton-like polyester fiber, which firstly produces a super-cotton-like polyester melt in a polyester synthesis device, and then directly imports it into spinning equipment to make a super-cotton-like polyester fiber The polyester fiber, the preparation method specifically comprises the following steps carried out continuously and successively:

[0044] (1) The first esterification reaction process: continuously add terephthalic acid and ethylene glycol in a molar ratio of 1:1 into the first esterification reaction kettle, and control the flow rate of terephthalic acid to 1700kg / h, Perform esterification reaction at 240°C to generate ethylene terephthalate;

[0045] (2) The second esterification reaction process: continuously feed the feed liquid in the first esterification reactor into the second esterification reactor, and feed ethylene glycol into the second esterif...

Embodiment 2

[0051] This embodiment provides a kind of preparation method of continuous polymerization melt direct spinning super cotton imitation polyester fiber, and preparation method specifically comprises the following steps that are carried out continuously successively:

[0052] (1) The first esterification reaction process: continuously add terephthalic acid and ethylene glycol in a molar ratio of 1:2 into the first esterification reaction kettle, and control the flow rate of terephthalic acid to 1700kg / h, Carry out esterification reaction at 230°C to generate ethylene terephthalate;

[0053] (2) The second esterification reaction process: continuously feed the feed liquid in the first esterification reactor into the second esterification reactor, and feed ethylene glycol into the second esterification reactor at a flow rate of 50kg / h , lower the temperature of the system to 200°C, and under the protection of nitrogen, accurately add the hygroscopic mother liquor to the second este...

Embodiment 3

[0059] This embodiment provides a kind of preparation method of continuous polymerization melt direct spinning super cotton imitation polyester fiber, and preparation method specifically comprises the following steps that are carried out continuously successively:

[0060] (1) The first esterification reaction process: continuously add terephthalic acid and ethylene glycol in a molar ratio of 1:1.5 into the first esterification reaction kettle, and control the flow rate of terephthalic acid to 1700kg / h, Carry out esterification reaction at 255°C to generate ethylene terephthalate;

[0061] (2) The second esterification reaction process: continuously feed the feed liquid in the first esterification reactor into the second esterification reactor, and feed ethylene glycol into the second esterification reactor at a flow rate of 50kg / h , lower the temperature of the system to 230°C, and under the protection of nitrogen, accurately add the hygroscopic mother liquor to the second es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com