Integrated waterproof leather preparation method

A tanning and process technology, which is applied in the field of clean leather manufacturing, can solve the problems of large fresh water consumption and achieve the effects of increased automation, water consumption control, precise addition of various chemicals, and improved cleaning and environmental protection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

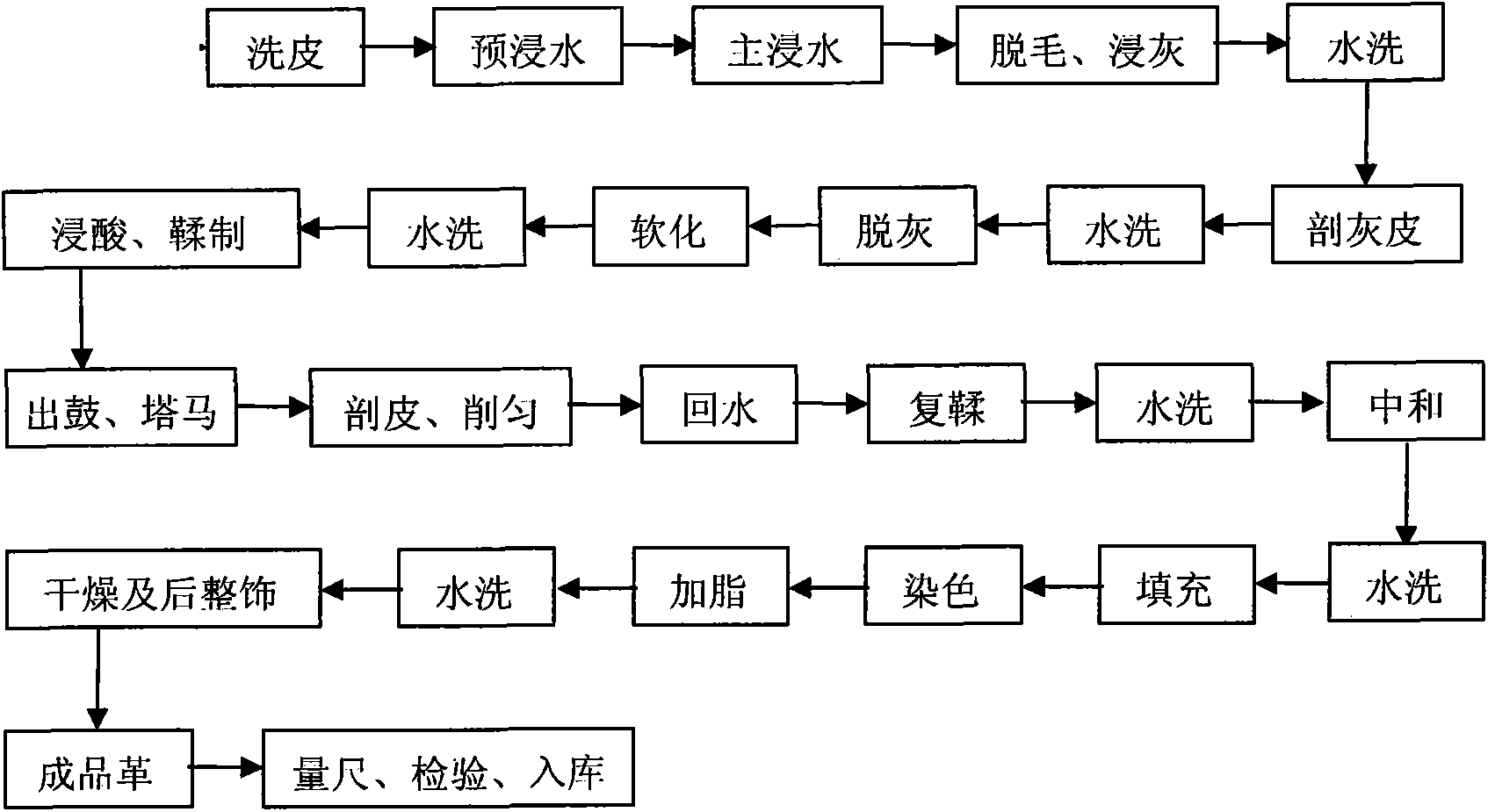

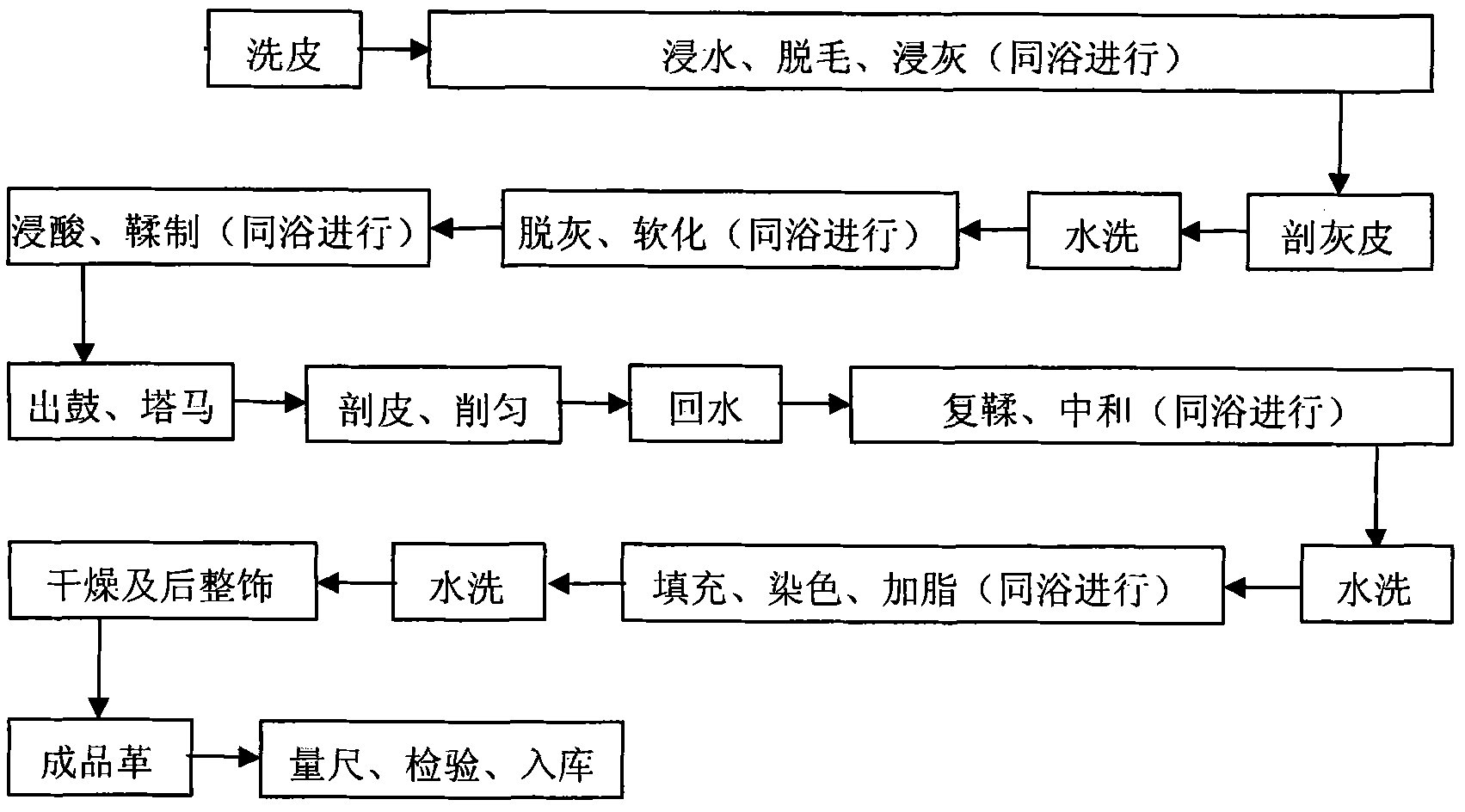

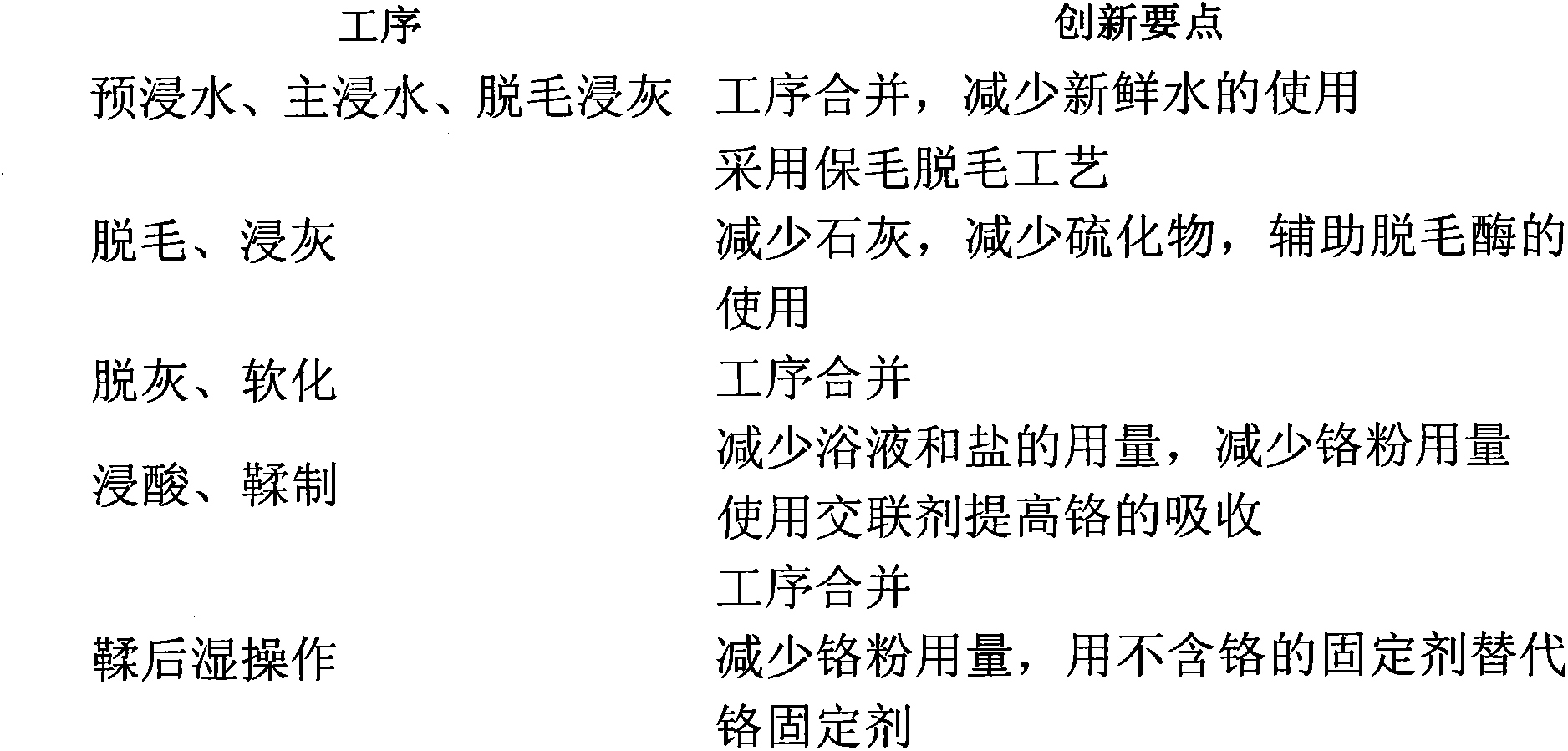

[0022] The present invention discloses an integrated water-saving tanning method, which is an improvement to the existing production method. For the specific process flow, see figure 2 .

[0023] Main technological process of the present invention is described as follows ( figure 2 Some of the conventional procedures will not be described in detail):

[0024] 1) Quick skin washing:

[0025] It is carried out in an overloaded drum, and the rotating speed of the drum is 2 to 4 rpm.

[0026] Take 100 parts of salt-wet cowhide, add 200 parts of fresh water, 0.05-0.2 parts of soaking aid A (LANXESS company, product name: CISMOLLAN SA-C, non-ionic polymer or non-ionic surfactant), 0.02-0.2 parts 0.2 parts of soaking enzyme (Derui TFL company, product name: PELLVIT C, composed of proteolytic enzyme and activator), 0.05-0.2 parts of fungicide (Shanghai Jiayi company, product name: 1140, organic sulfide). The temperature is 20-25°C. Rotate for 30 minutes, stop for 30 minutes, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com