Additive metering device for mixing mortar for construction

A metering device and admixture technology, which is applied in the direction of liquid ingredient supply device, etc., can solve the problems of temperature error, observation error, and difficult observation by observers, and achieve the effect of avoiding temperature error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

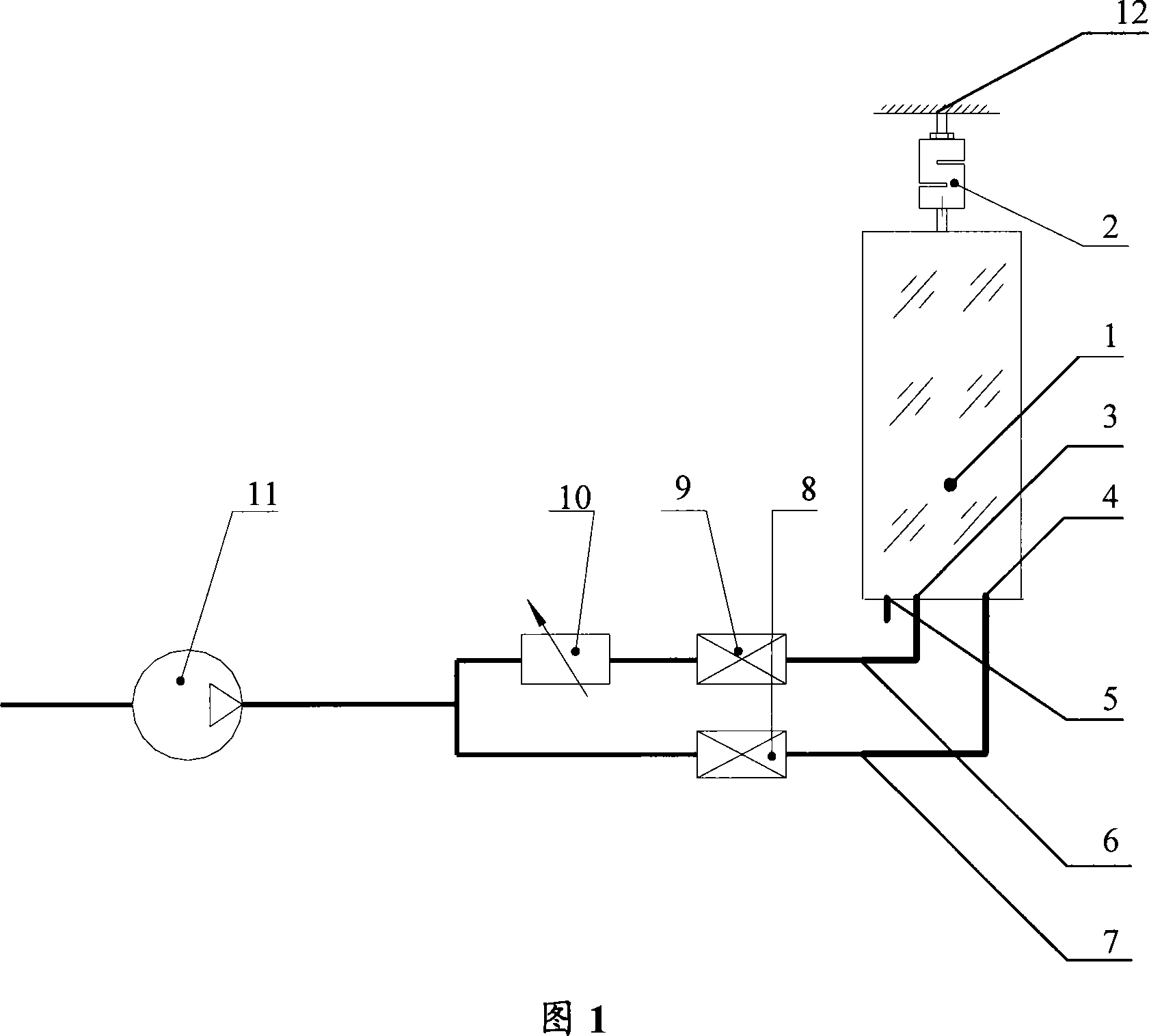

[0017] Please refer to FIG. 1 , which shows a schematic structural view of an admixture metering device for mixing construction mortar provided by the first embodiment of the present invention.

[0018] As shown in the figure, the metering container 1 of the admixture metering device is suspended on the frame 12 through the suspension rod installed with the load cell 2, and the bottom of the metering container 1 is provided with an admixture outlet 5, and the admixture outlet 5 The setting position can make the admixture loaded into the metering container 1 flow out from the outlet. The admixture outlet 5 is equipped with a control outlet opening or closing valve (not shown), so that the outlet can be in an open or closed state as required. The load cell 2 can weigh the weight of the metering container 1 and the additive therein, and the user can obtain the accurate weight of the additive by subtracting the weight of the metering container 1 from the value. In addition, in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com