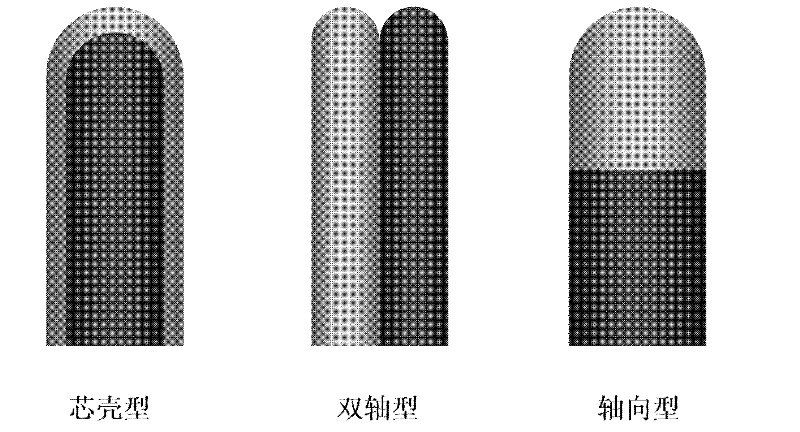

One-dimensional axial type nano zinc oxide / zinc sulfide heterojunction and preparation method thereof

A technology of nano-zinc oxide and nano-zinc sulfide, applied in the field of nano-materials, can solve the problems of inability to prepare one-dimensional axial zinc oxide/zinc sulfide heterojunction, limited performance and application, insufficient preparation methods, etc., and achieve cost Low cost, scientific preparation method, uniform product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

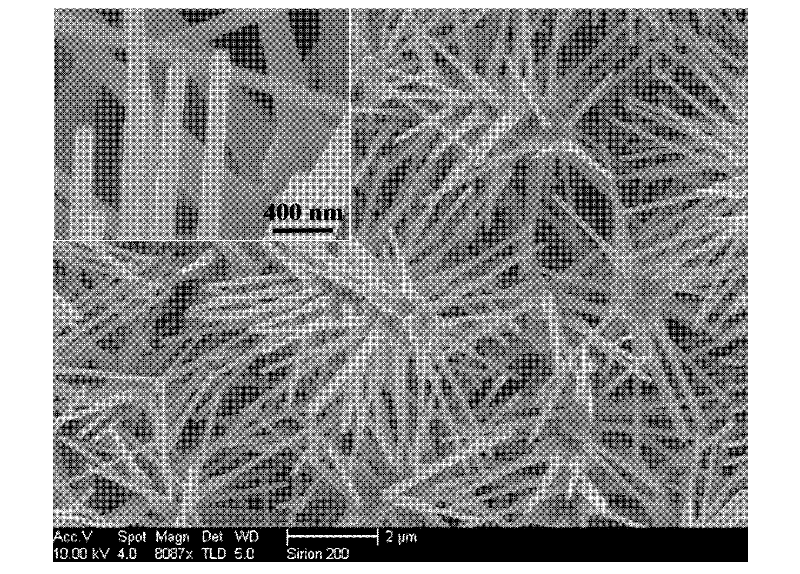

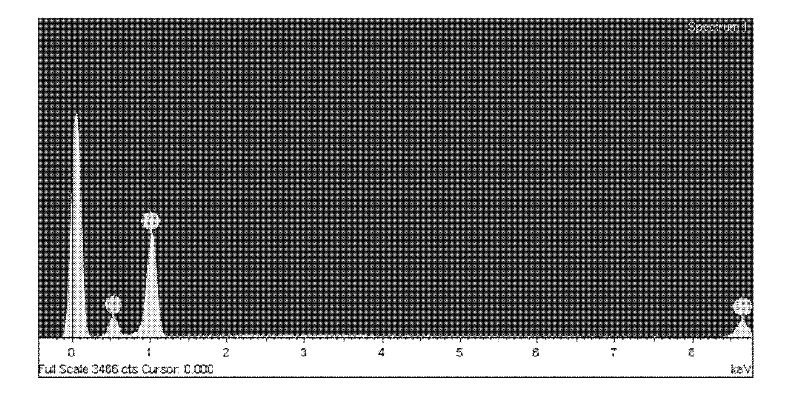

[0040] Step 1, after mixing and grinding zinc oxide powder and graphite powder at a mass ratio of 3:1, take 0.40g of the mixture and put it into a ceramic boat and place it in the center of the tube furnace; place the silicon wafer upright on the downstream side of the tube furnace At 10 cm in the center, the rough surface faces the direction of the mixed powder of zinc oxide and graphite, which serves as the substrate for the growth of zinc oxide nanostructures; the tube furnace is heated to 950 °C, the heating rate is 100 °C / min, and the holding time is 60 min. A zinc oxide flower-like structure similar to that shown in Figure (2) SEM results and corresponding to the EDS curve in Figure (3) was obtained, and a large number of zinc oxide nanorods grew on each flower-like unit.

[0041] In step 2, a gold film of about 3 nm is sputtered on the silicon wafer on which zinc oxide nanorods are grown, and then kept in air at 800° C. for 30 minutes to obtain an intermediate product. ...

Embodiment 2

[0043] The concrete steps of preparation are:

[0044] Step 1, after mixing and grinding zinc oxide powder and graphite powder at a mass ratio of 3.5:1, take 0.45g of the mixture and put it into a ceramic boat and place it in the center of the tube furnace; place the silicon chip upright in the downstream distance of the tube furnace At 10.5 cm in the center, the rough surface faces the direction of the mixed powder of zinc oxide and graphite, which is used as the substrate for the growth of zinc oxide nanostructures; the tube furnace is heated to 975 ° C, the heating rate is 100 ° C / min, and the holding time is 70 min. A zinc oxide flower-like structure similar to that shown in Figure (2) SEM results and corresponding to the EDS curve in Figure (3) was obtained, and a large number of zinc oxide nanorods grew on each flower-like unit.

[0045] In step 2, a gold film of about 2nm is sputtered on the silicon wafer grown with zinc oxide nanorods, and then kept in air at 850° C....

Embodiment 3

[0047] The concrete steps of preparation are:

[0048] Step 1, after mixing and grinding zinc oxide powder and graphite powder at a mass ratio of 4:1, take 0.50 g of the mixture and put it into a ceramic boat and place it in the center of the tube furnace; place the silicon wafer upright in the downstream distance of the tube furnace At 11cm in the center, the rough surface faces the direction of the mixed powder of zinc oxide and graphite, which is used as the substrate for the growth of zinc oxide nanostructures; the tube furnace is heated to 1000°C, the heating rate is 100°C / min, and the holding time is 80min. The ZnO flower-like structure shown in Figure (2) SEM results and corresponding to the EDS curve in Figure (3) was obtained, and a large number of ZnO nanorods grew on each flower-like unit.

[0049] In step 2, a gold film with a thickness of about 3 nm is sputtered on the silicon wafer grown with zinc oxide nanorods, and then kept in air at 900° C. for 50 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com