Preparing method for abrasion-resisting steel with oriented growth carbide

A technology of directional growth and carbide, which is applied in the field of preparation of wear-resistant steel, can solve the problems of the influence of alloy materials and the inapplicability of preparation of wear-resistant steel materials, etc., and achieve the effect of strong hardness, high strength and accurate element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below by means of specific embodiments:

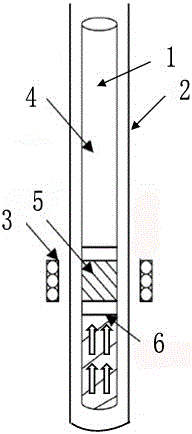

[0036] The reference signs in the drawings of the description include: sample rod 1 , quartz tube 2 , coil 3 , unmelted zone 4 , melting zone 5 , and resolidified zone 6 .

[0037] Among them, graphite powder, high-purity iron powder, tungsten, molybdenum, chromium, and vanadium are represented by their chemical symbols, namely: C, Fe, W, Mo, Cr, V. According to graphite powder, high-purity iron powder, the different contents of alloy powder (see Table 1) and make embodiment 1-7 seven groups of different wear-resistant steels. like figure 1 As shown, the specific process is as follows:

[0038] Step 1: First, weigh graphite powder, high-purity iron powder, and alloy powder according to the mass percentages in Table 1, and then put the prepared materials into a ball mill tank for ball milling, wherein the ratio of balls to materials is 10:1;

[0039] Step 2: Take out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com