Method for manufacturing film resistance

A technology of thin film resistors and manufacturing methods, applied to resistors, non-adjustable metal resistors, circuits, etc., can solve problems such as defective products, incomplete removal, and contamination by fine dust, so as to improve the yield rate and stabilize the characteristics of the resistive film , The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following embodiments, a single thin-film resistor is chosen for illustration, but those skilled in the art will know that a plurality of thin-film resistors arranged in a matrix can be formed on a large insulating substrate during actual manufacturing.

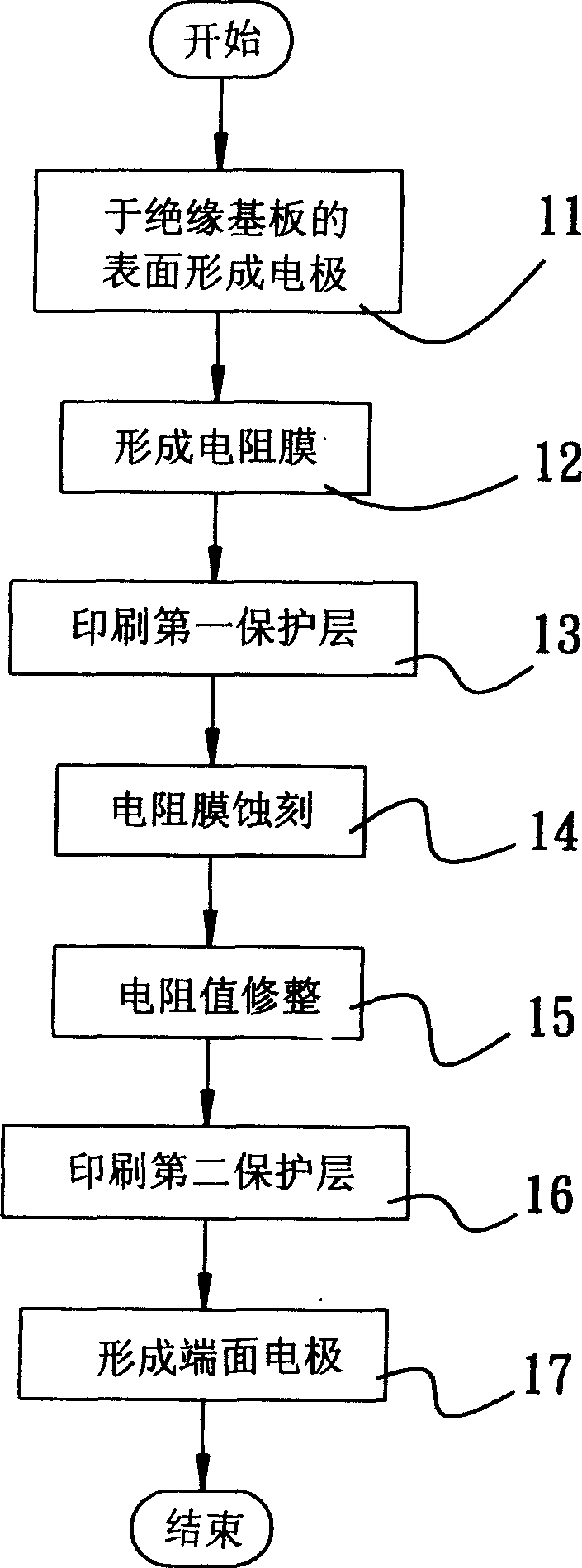

[0028] refer to figure 1 , the manufacturing process of a preferred embodiment of the manufacturing method of the thin film resistor of the present invention. In order to make this embodiment easier to understand, the following will cooperate Figure 2 to Figure 9 The manufacturing process of this embodiment will be described.

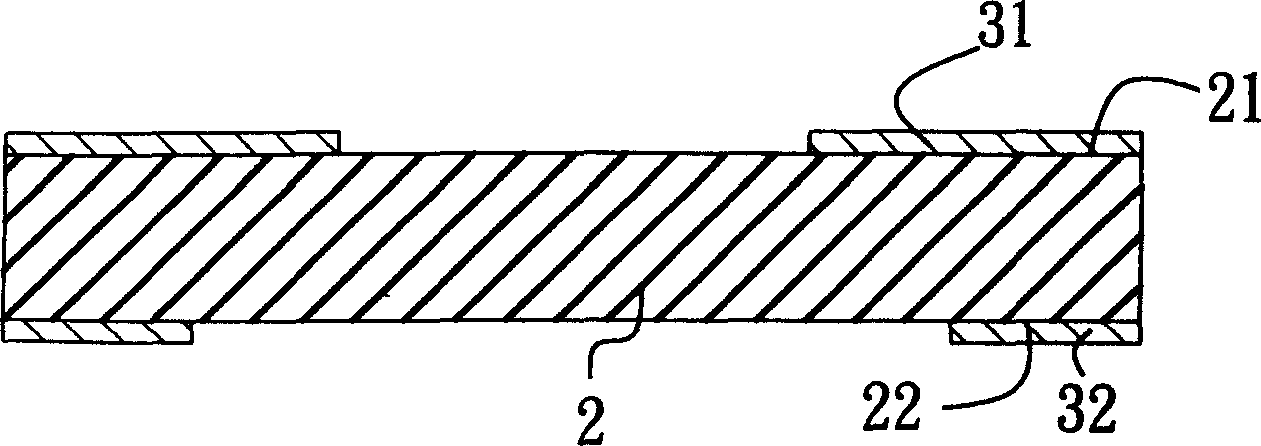

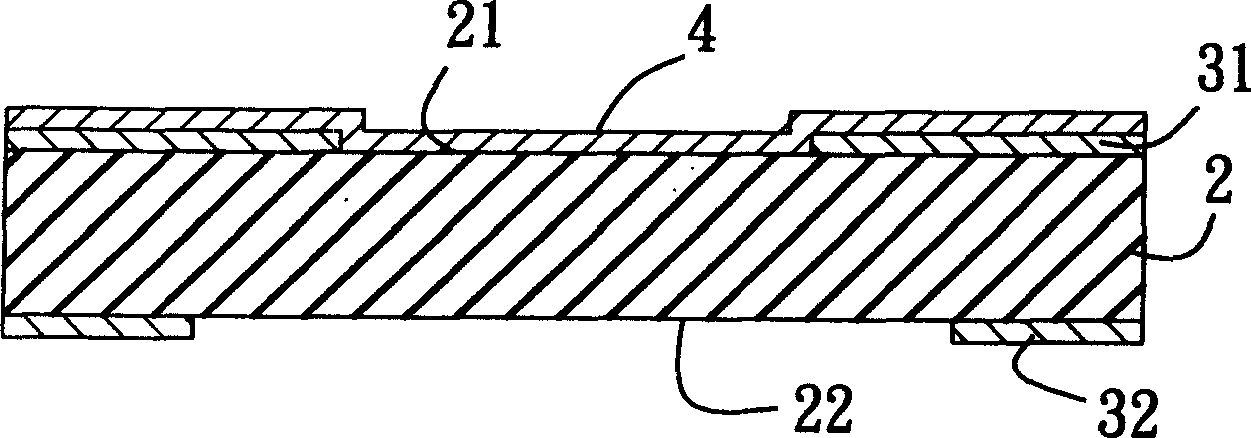

[0029] Firstly, step 11 is to form electrodes on the surface of an insulating substrate 2 . Such as figure 2 , two main electrodes 31 are respectively formed on two ends of the upper surface 21 of the insulating substrate 2 . In addition, in this embodiment, two bottom electrodes 32 can be formed on both ends of the bottom surface 22 of the insulating substrate 2 for bonding on a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com