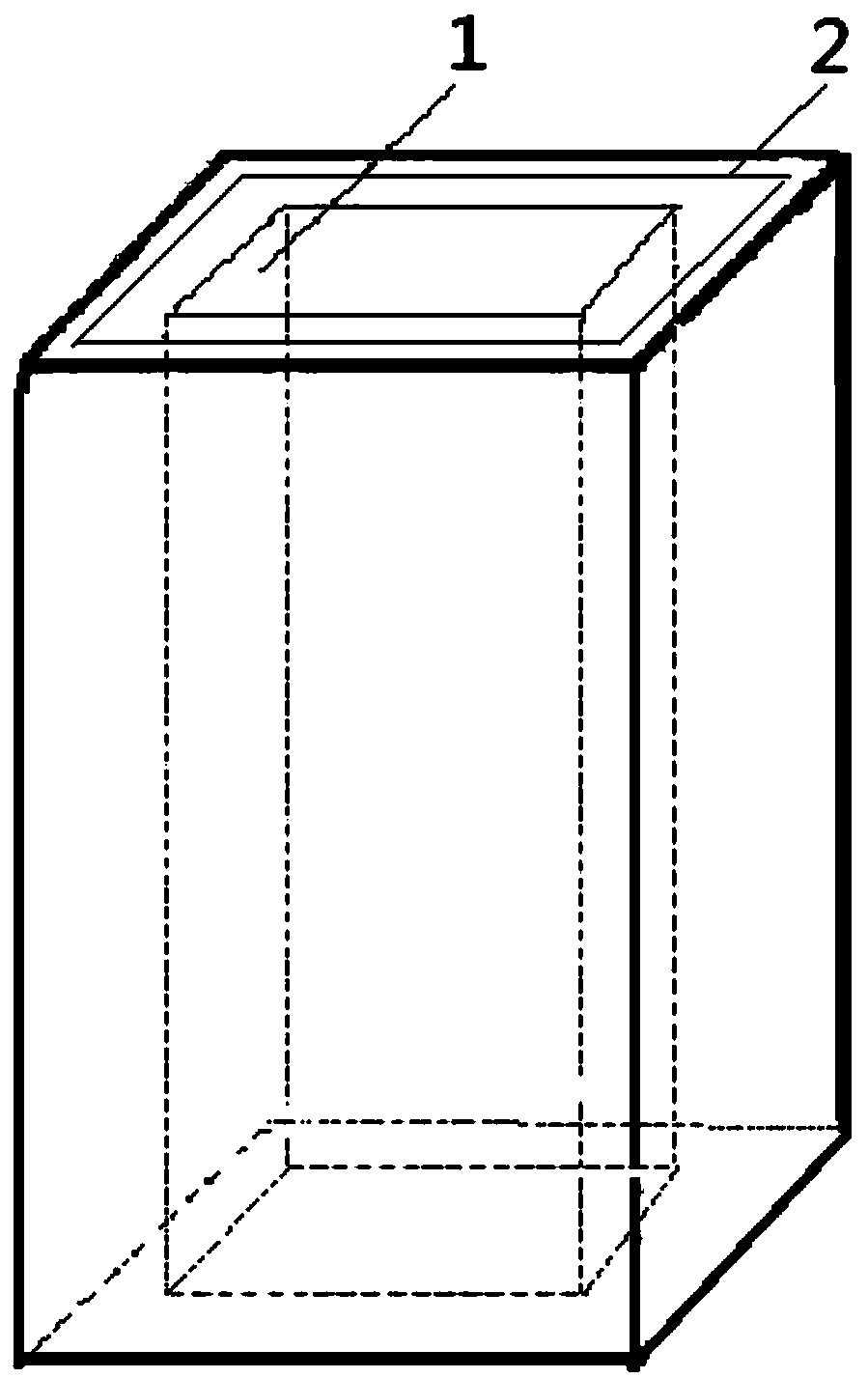

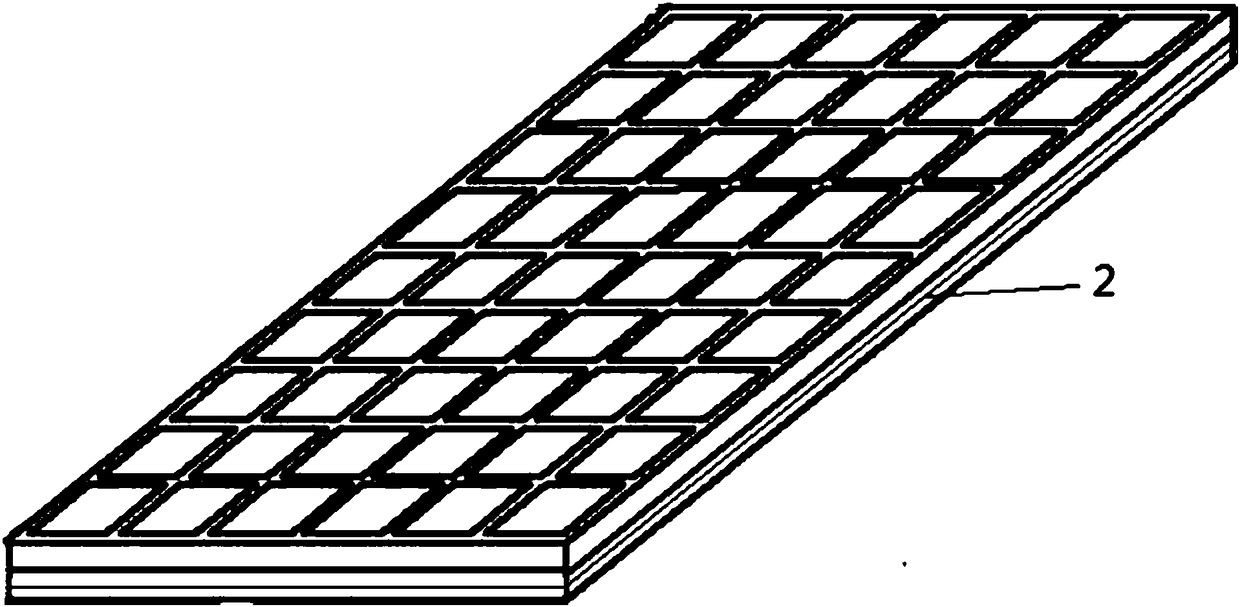

Manufacturing method for TRC inner wall grating type permanent formwork

A manufacturing method and permanent technology, applied in the direction of manufacturing tools, climate sustainability, sustainable waste treatment, etc., can solve the problems of TRC permanent formwork and cast-in-place concrete stripping, hollowing, etc., to ensure synergistic force bearing , Improve interface bonding performance, reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: TRC inner wall grid type permanent formwork manufacturing method, comprising the following steps:

[0050] Step 1, fiber woven mesh surface dipping and sandblasting;

[0051] Step 2. Install the internal mold required for the grid-type inner wall of the TRC permanent formwork;

[0052] Step 3, outer mold installation;

[0053] Step 4, placing the fiber woven net;

[0054] Step 5, pouring high-performance fine concrete and curing;

[0055] Step 6, demoulding.

[0056] The steps of step 1, surface dipping and sandblasting of the fiber woven mesh are as follows:

[0057] (1) The implementation method of impregnating the fiber woven mesh; first weave the fiber woven mesh, and then fix it to the PVC plastic sheet according to the required template shape to form the required fiber woven mesh shape; then brush the configured epoxy The resin coating solution is evenly applied on the fiber woven mesh, and the whole process should be careful not to cause knots ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com