Technology for making pressure bearing member of reinforced concrete

A compression member and concrete technology, which is applied in the direction of building structure, construction, building maintenance, etc., can solve the problems of less research on the situation of multi-material composite reinforcement, achieve good reinforcement effects, reduce engineering costs, and reduce engineering investment. The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

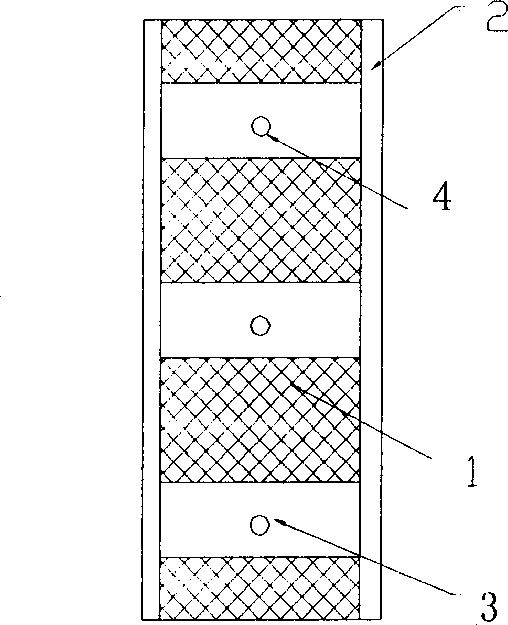

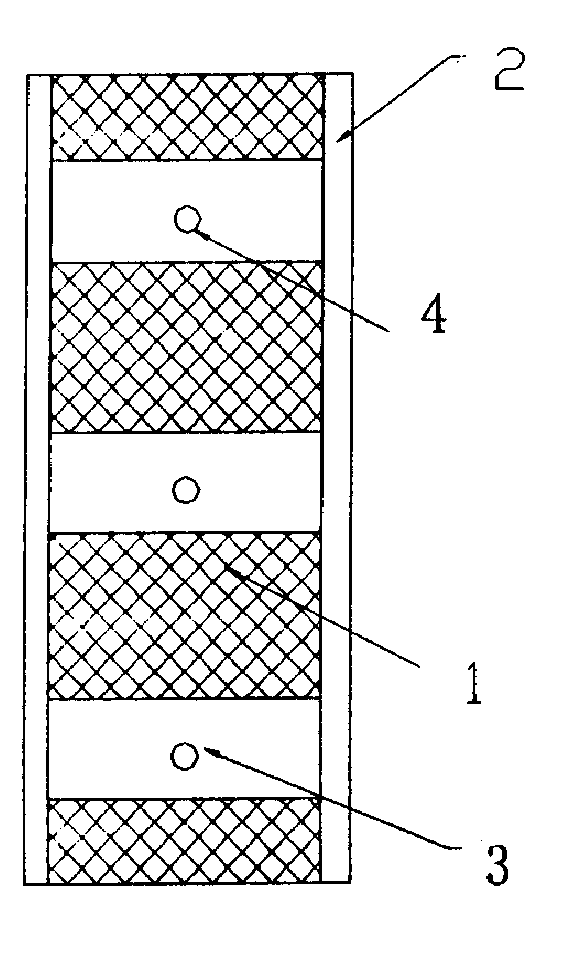

[0010] Referring to the attached figure, the fiber-reinforced plastic (FRP) is pasted around the compression member with a fiber adhesive to restrain the lateral deformation of the concrete, and the four corners of the concrete member covered with fiber-reinforced plastic (FRP) are glued with building structures Attach profile steel 2, profile steel 2 directly bears a part of the load, so as to directly pass the bearing capacity of the compression member, and at the same time weld the steel panel 3 and profile steel 2 to form a steel skeleton system, and then integrate it with the concrete through bolts 4, that is Realize the reinforcement of concrete compression members.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com