Construction method of high-ductility fiber concrete floor cast-in-place layer

A fiber-reinforced concrete and construction method technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of limited improvement of structural integrity and seismic performance, self-heavy cast-in-place concrete surface, complex construction technology, etc. Achieve the effect of improving the integrity and anti-seismic performance, enhancing the bonding performance, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

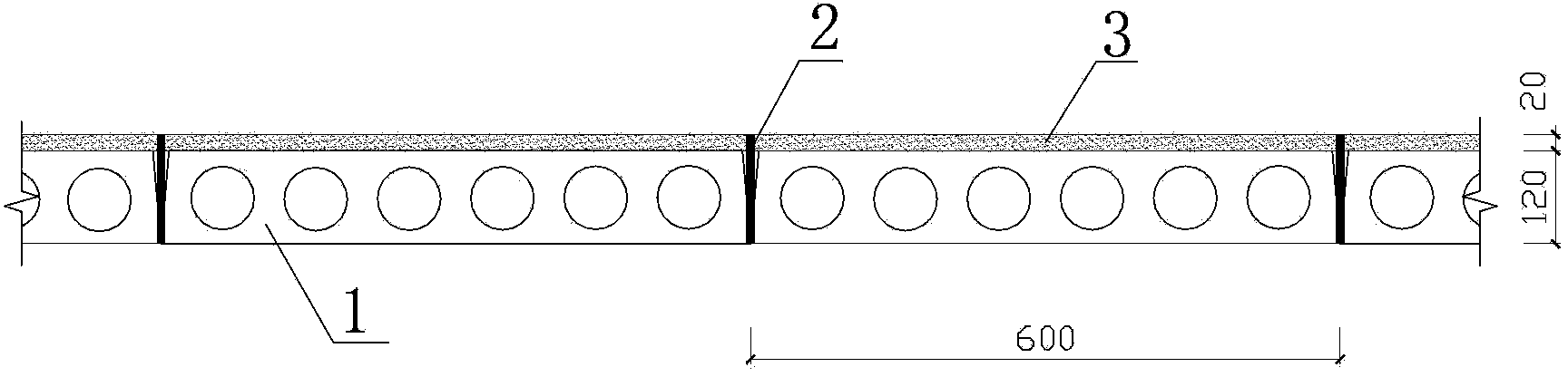

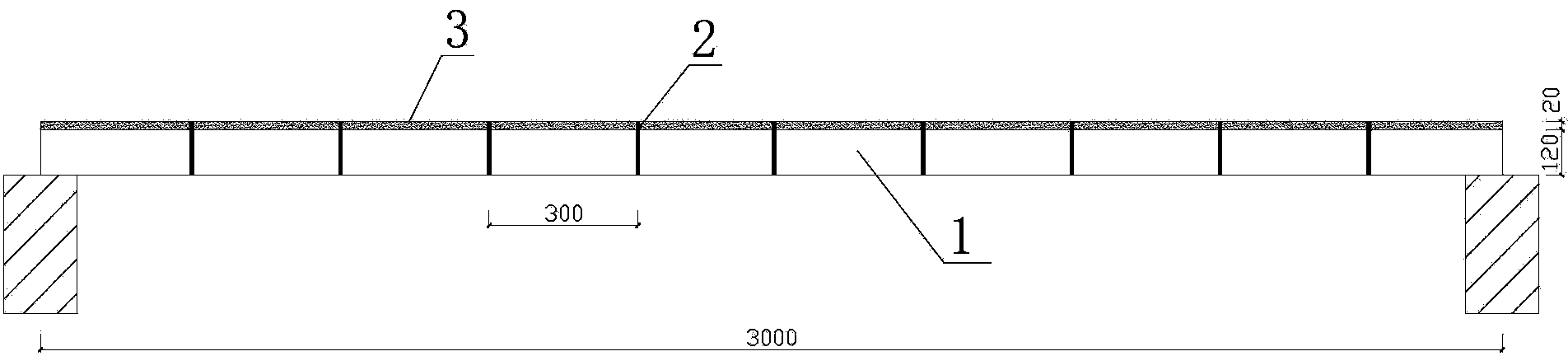

[0022] Follow the technical scheme of the present invention, such as figure 1 and figure 2 As shown, in this example, the prefabricated floor 1 adopts a one-way circular hole plate, the plate span is 3m, the width is 600mm, and the thickness is 120mm. After the prefabricated floor 1 is hoisted in place, short steel bars 2 with a diameter of 12mm are implanted every 300mm at the joints of the prefabricated floor 1. The upper part of the prefabricated floor 1 after treatment is poured with 20 mm thick high ductility fiber concrete, and after curing for 3 days, the integral layer of high ductility fiber concrete floor is obtained.

[0023] The components of the above-mentioned high ductility fiber concrete are cement, fly ash, silica fume, sand, PVA fiber, water reducer and water, wherein, by mass percentage, cement: fly ash: silica fume: sand: water = 1: 0.9: 0.1: 0.76: 0.58; based on the total volume of cement, fly ash, silica fume, sand and water mixed uniformly, the volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com