Steel-ECC-concrete composite beam and preparation method thereof

A technology of concrete and composite beams, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of reduced overall structure stiffness, influence of shear key performance, and reduced ultimate bearing capacity, so as to increase bearing capacity and improve stress Ability, life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention. However, it should be clear that the embodiments described below are only some, not all, embodiments of the present invention. Without departing from the spirit and scope of the present invention defined and determined by the appended claims, all other embodiments obtained by persons of ordinary skill in the art without any creative effort shall fall within the protection scope of the present invention.

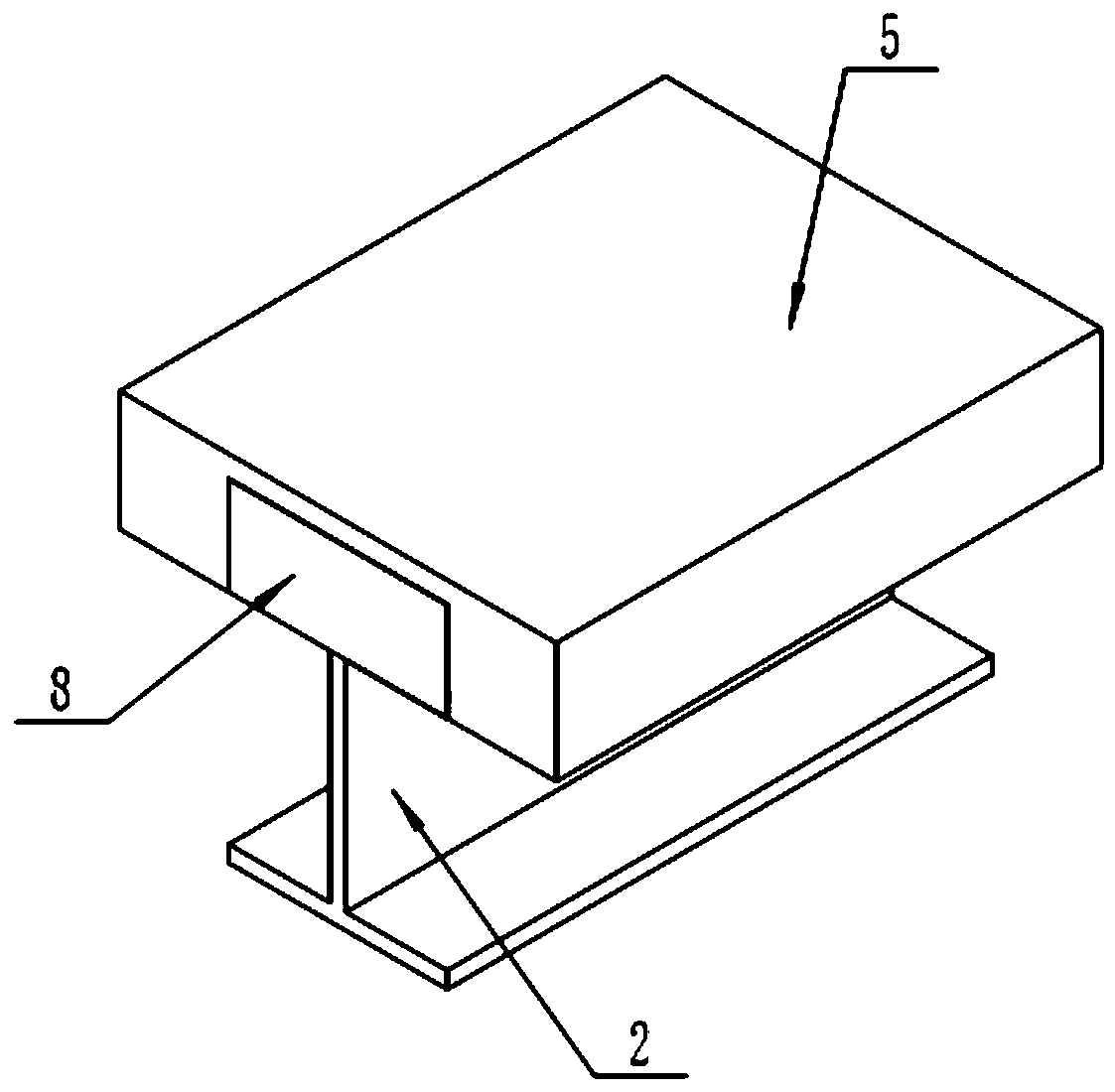

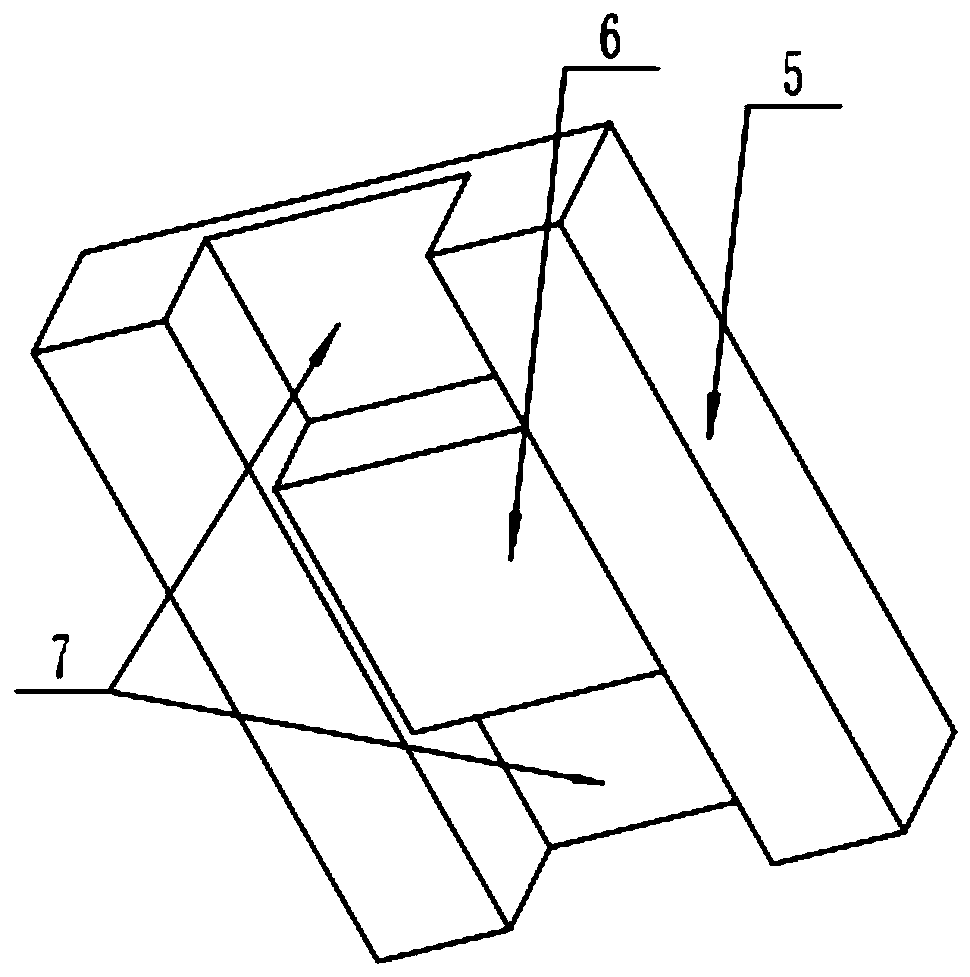

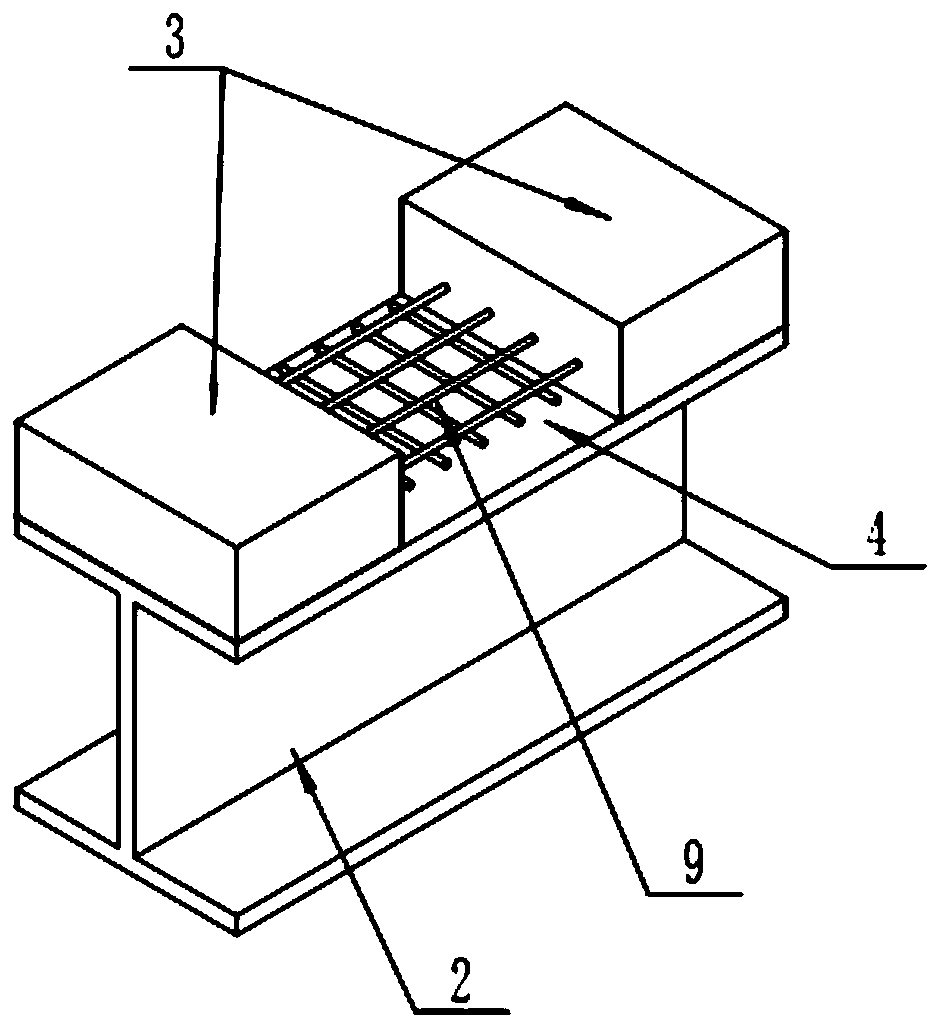

[0027] Such as Figure 1 to Figure 4 As shown, the steel-ECC-concrete composite beam includes a steel beam 1, at least two sets of shear bond groups 2, and ECC protection blocks 3 corresponding to the number of shear bond groups 2 ("ECC" is a cement-based reinforced composite for engineering use) The abbreviation of the material) and the concrete slab 5 with steel bars ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Web thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com