The steel-tube grouting quick-stabilizing column structure and construction method

A column structure and steel pipe technology, applied in building construction, building maintenance, construction, etc., can solve the problems of large column section, slow construction speed, complicated construction procedures, etc., to improve bearing capacity, fast construction speed, and avoid local buckling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In a specific implementation process, the cross-sectional form of the steel pipe grouting rapid reinforcement column structure of the present invention may be circular or square.

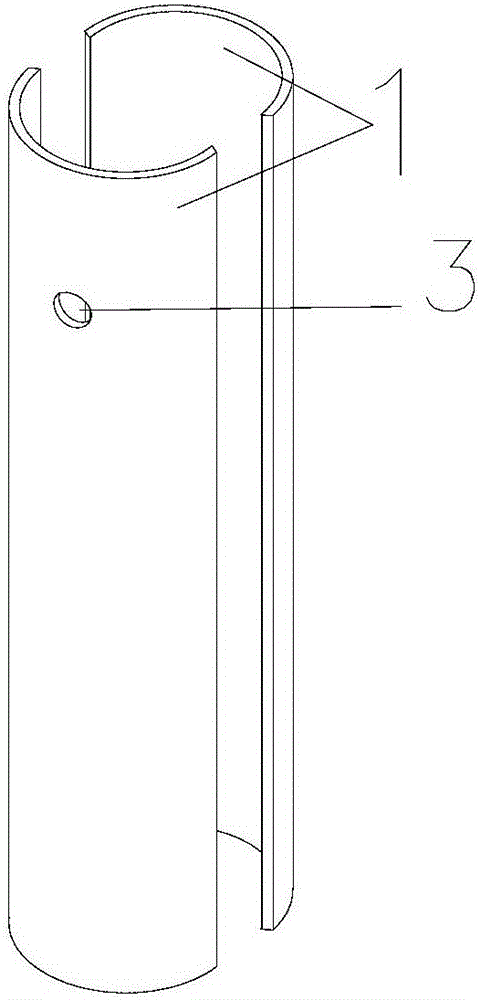

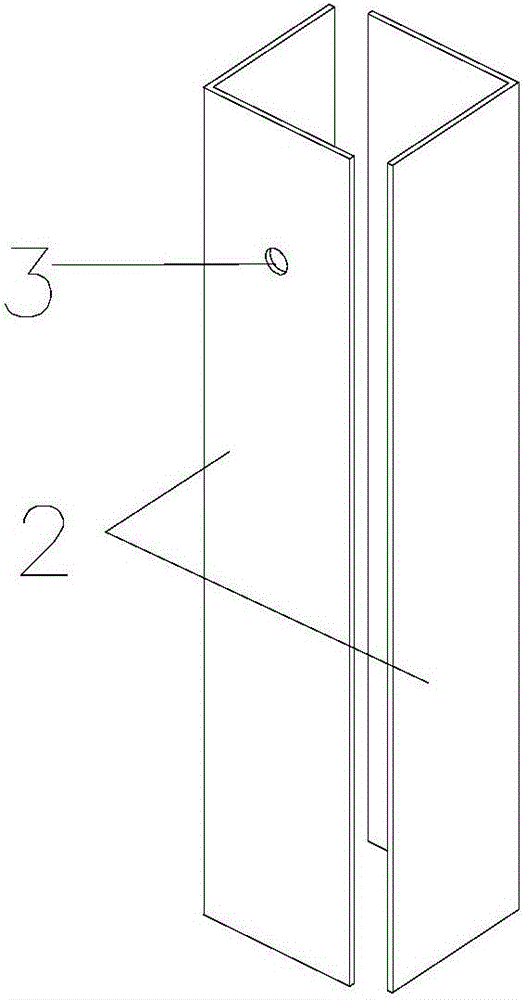

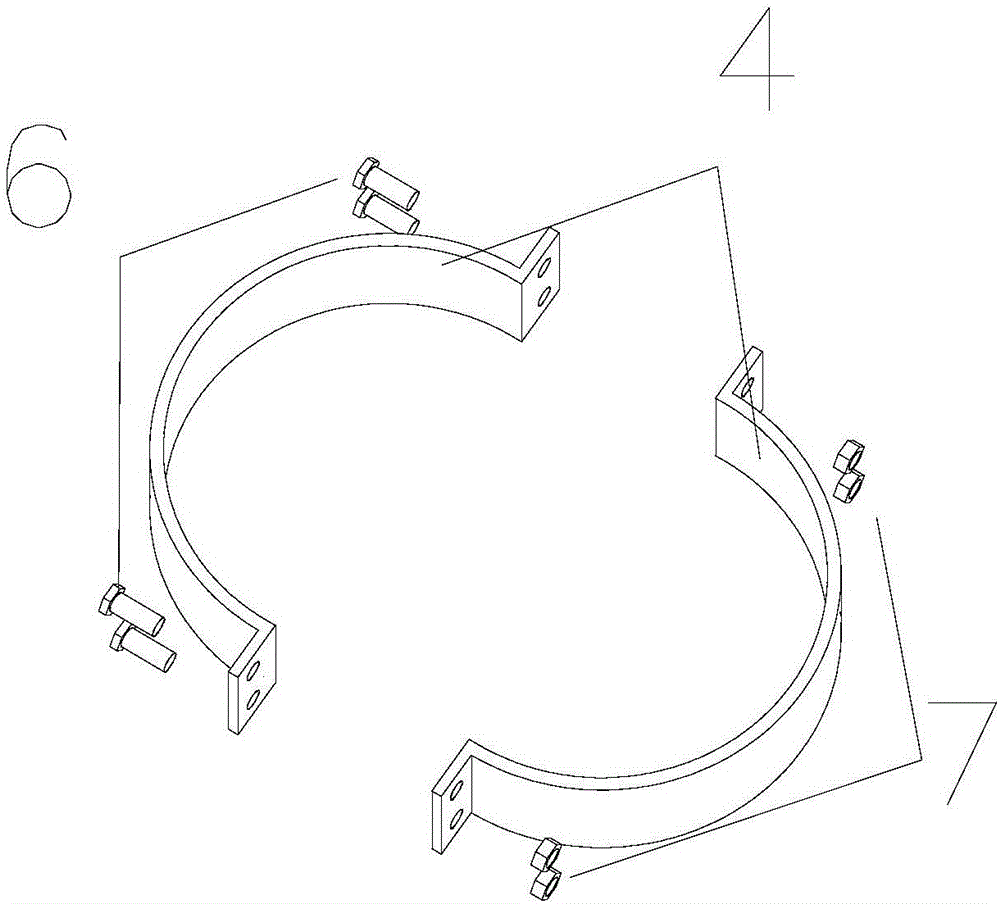

[0043] like Figure 1-Figure 15 As shown, the steel pipe grouting rapid strengthening column structure of the present invention mainly includes: semi-outsourcing round steel pipe 1, semi-outsourcing square steel pipe 2, grouting hole 3, annular restraint hoop 4, square restraint hoop 5, bolt 6, nut 7, PVC Grouting pipe 8, quick-drying glue 9, high-strength grouting material 10, ordinary reinforced concrete column 11, ordinary reinforced concrete square column 12, etc. The specific structure is as follows:

[0044] like figure 1 , Figure 10 As shown, the inner diameters of the two half-wrapped round steel pipes 1 in the present invention are larger than the outer diameters of common reinforced concrete cylinders 11, and the specific values of the outer diameters of common reinforced concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com