Full-bolt-assembly type steel framework light plate and manufacturing method thereof

A kind of steel frame light plate, prefabricated technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of building indoor net height, difficult to guarantee welding seam quality, unreliable connection, etc., to achieve reasonable structure and improve installation efficiency. , improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

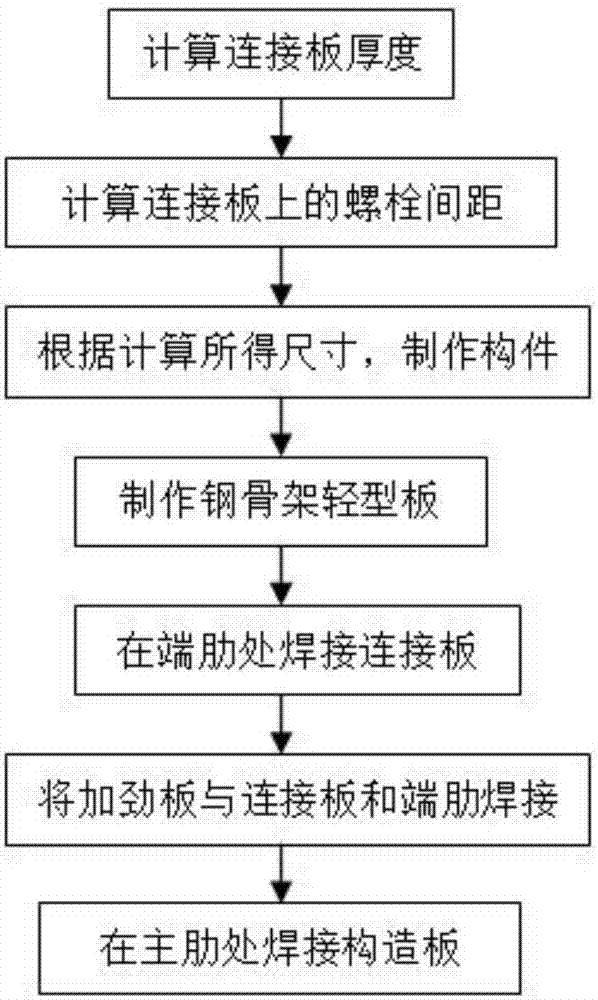

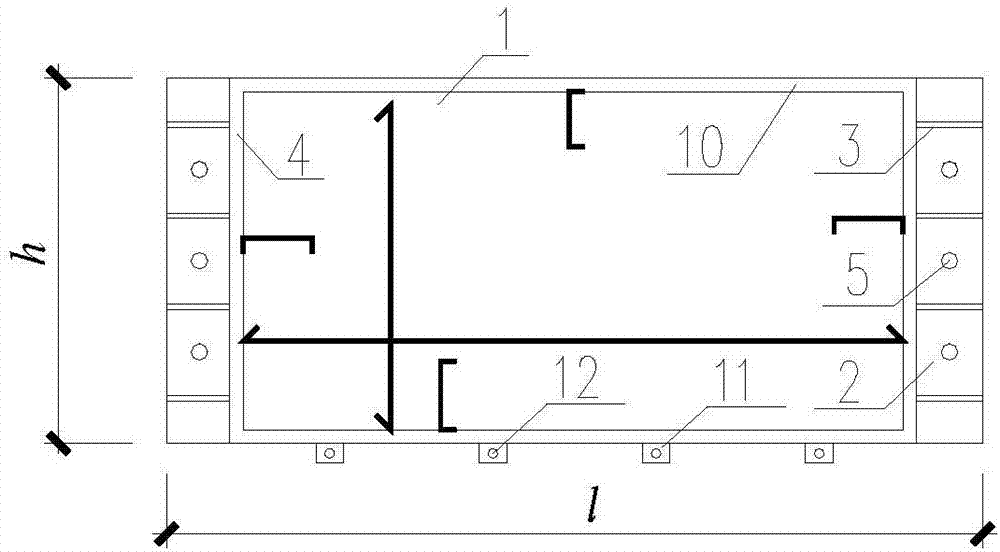

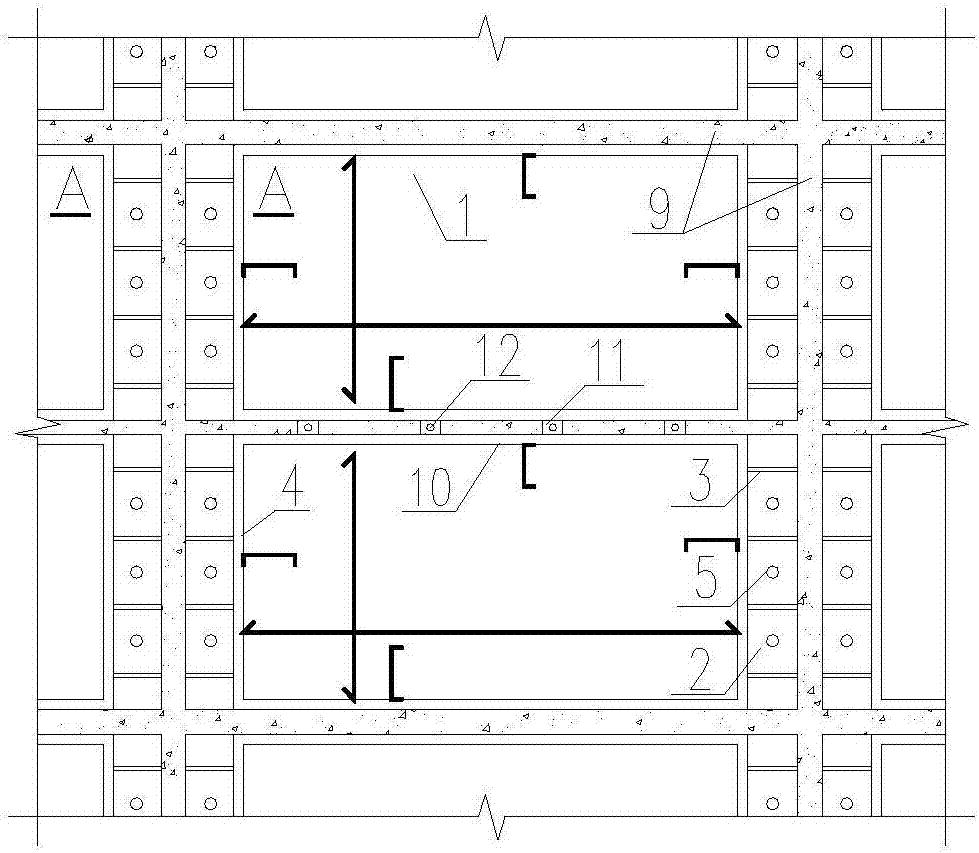

[0038] A fully bolt-assembled steel frame light-duty panel, the main structure includes a steel-frame light-duty panel 1, a connecting plate 2, a stiffening plate 3, and a structural panel 11, wherein the length of the steel-frame light-duty panel is l=4500mm, and the width h=1000mm; in the factory The light-weight steel frame slab 1 is manufactured, and the steel-frame light-weight slab 1 is arranged with stress bars and distribution bars. The distribution bars are φ6@200, and the main ribs and end ribs of the steel-frame light slab are C160×50×20×3 The channel steel; the connecting plate 2 is welded at the end rib 4 of the steel skeleton light plate 1 through a single-sided gap weld, and the structural plate 11 is welded at the main rib 10, and the connecting plate 2 is pre-opened in the processing plant. Bolt holes 5 , the structural plate 11 has bolt holes 12 pre-opened in the processing plant; a stiffening plate 3 is arranged in the middle of the adjacent bolt holes 5 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com