Built-in truss combined structure

A combined structure and truss technology, applied to building components, building structures, walls, etc., can solve problems such as complex manufacturing process and wall thickness restrictions, and achieve good mechanical properties and superior energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

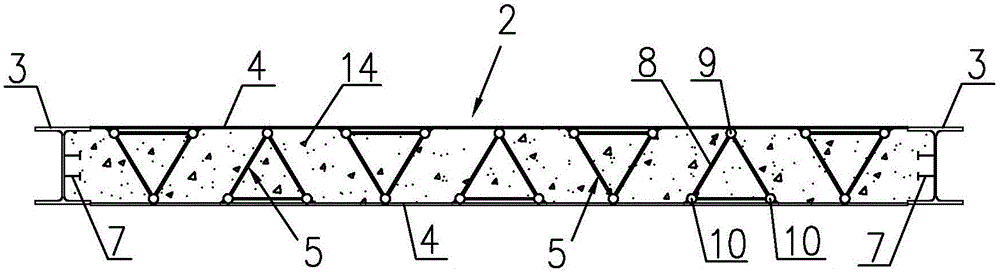

[0041] Embodiment 1 includes a combined body 2, the combined body 2 is composed of an end column 3 and a steel plate 4, and the end column 3 and the steel plate 4 are welded and fixed. The steel plates 4 on both sides are arranged in parallel up and down, and the end columns 3 are fixed on both ends of the steel plates 4, and the two end columns 3 and the two steel plates 4 form a straight shape. A cavity is formed between the end column 3 and the steel plate 4, and a triangular truss 5 is separately arranged in the cavity, and the triangular truss 5 is welded to the steel plate at equidistant distances, and two adjacent triangular trusses 5 are arranged in rotation. A shear member 7 is provided on the inner side of the end column, and two laterally adjacent shear members 7 are arranged symmetrically. Concrete 14 is poured in the cavity, and the triangular truss 5 and the shear member 7 are all set in the concrete 14 .

Embodiment 2

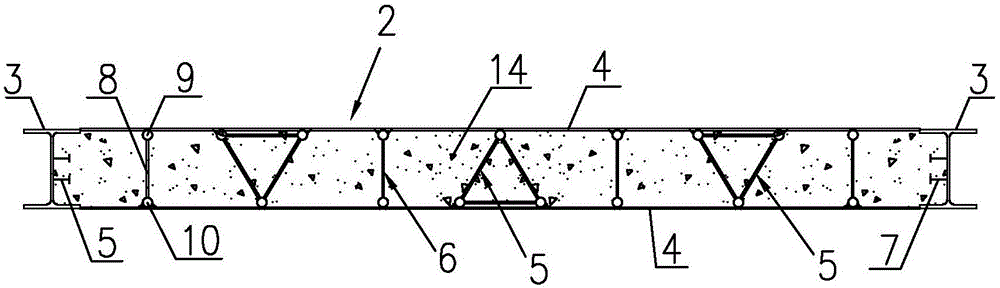

[0042] The second embodiment includes a combined body 2, the combined body 2 is composed of an end column 3 and a steel plate 4, and the end column 3 and the steel plate 4 are welded and fixed. The steel plates 4 on both sides are arranged in parallel up and down, and the end columns 3 are fixed on both ends of the steel plates 4, and the two end columns 3 and the two steel plates 4 form a straight shape. A cavity is formed between the end column 3 and the steel plate 4, and a triangular truss 5 and a planar truss 6 are arranged in cooperation with each other in the cavity. The distance is welded on the steel plate 4, and two adjacent triangular trusses 5 are arranged in rotation. A shear member 7 is provided on the inner side of the end column, and two laterally adjacent shear members 7 are arranged symmetrically. Concrete 14 is poured in the cavity, and the triangular truss 5 and the shear member 7 are all set in the concrete 14 .

[0043] Such as image 3 and Figure 4 ...

Embodiment 3

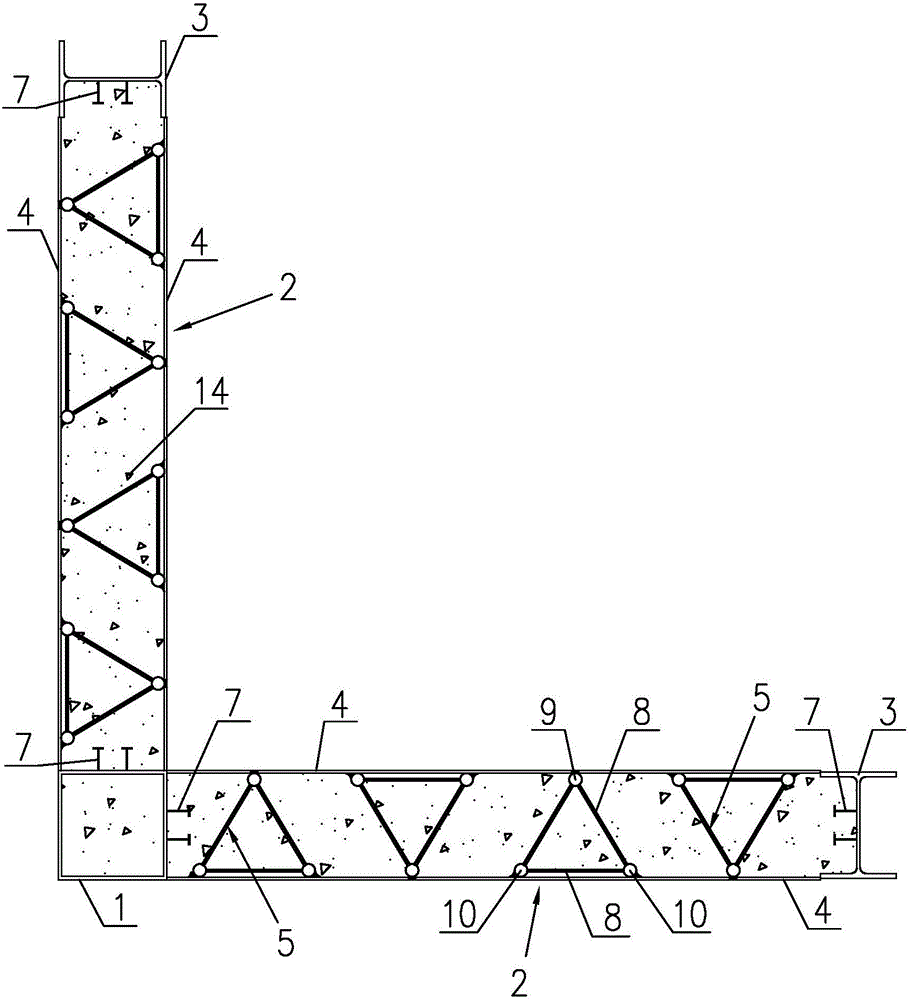

[0044]Embodiment 3 includes a combination body 2, one end of the combination body 2 is provided with a corner post 1, the corner post 1 adopts a rectangular tube or a square tube, the combination body 2 is arranged on two intersecting sides of the corner post 1, the corner post 1 and the two combination bodies 2 form an L shape. The combined body 2 includes an end column 3 and a steel plate 4, and the end column 3 and the steel plate 4 are fixed by welding. The steel plates 4 on both sides are arranged in parallel up and down, and the steel plates 4 are fixed between the end columns 3 and the sides of the corner columns 1 . A cavity is formed between the end column 3, the steel plate 4 and the corner column 1, and a triangular truss 5 is separately arranged in the cavity, and the triangular truss 5 is welded to the steel plate 4 at equal distances, and two adjacent triangular trusses 5 are rotated. The inner side of the end column 3 is provided with a shear member 7, and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com