Patents

Literature

37results about How to "Reduce the difficulty of construction operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

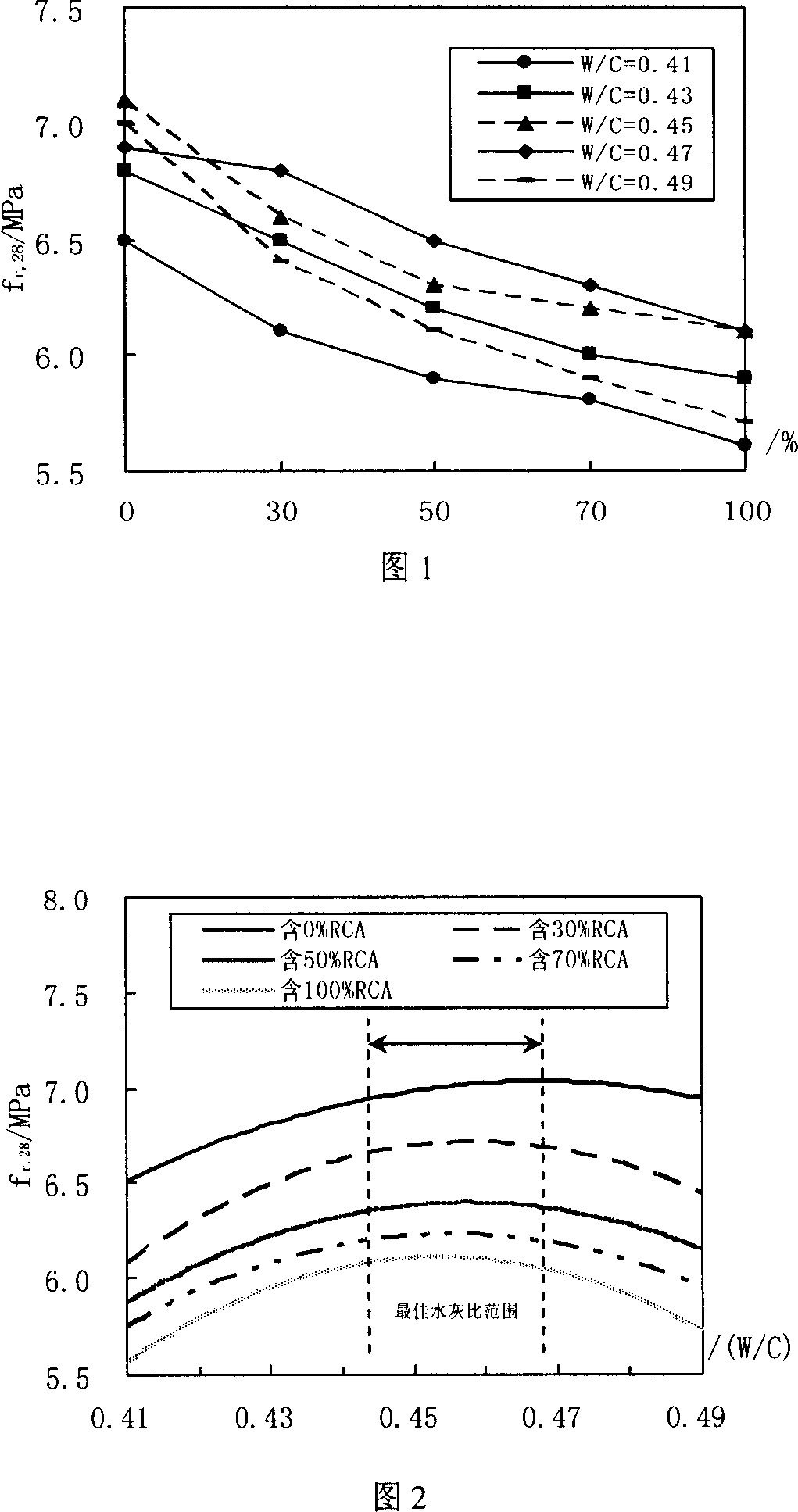

Regenerated cement concrete for pavement and its preparing process

InactiveCN1951859AImprove flexural strengthImprove toughnessSolid waste managementFiberSuperplasticizer

The invention discloses a new road regenerating cement concrete and preparing method, which comprises the following parts: 15%-37% regenerating rough aggregate, 15%- 37% natural rough aggregate, 16%-18% cement, 22%-24% sand, 8%-10% water (mixing water and additional water), 0.6%-1.2% steel fiber corresponding to the sum of component bulk and 0.1%-0.5% high-effect water reducer corresponding to cement quantity. The invention overcomes low bending-proof strength, which improves cracking-proof flexibility and impaction-proof ability greatly.

Owner:王军龙

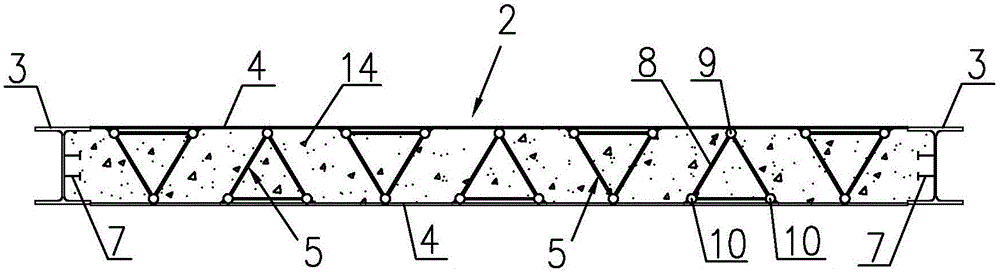

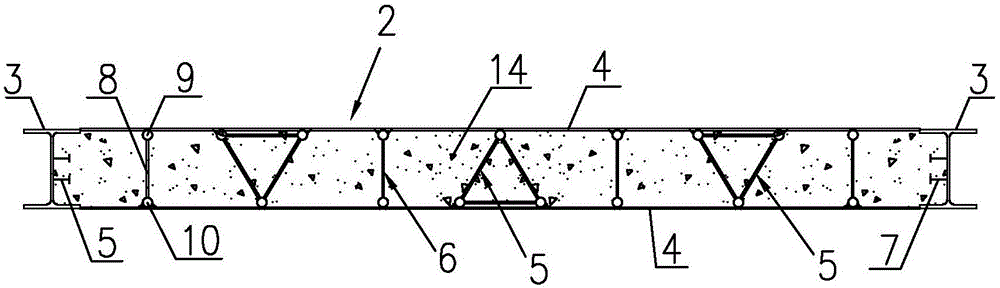

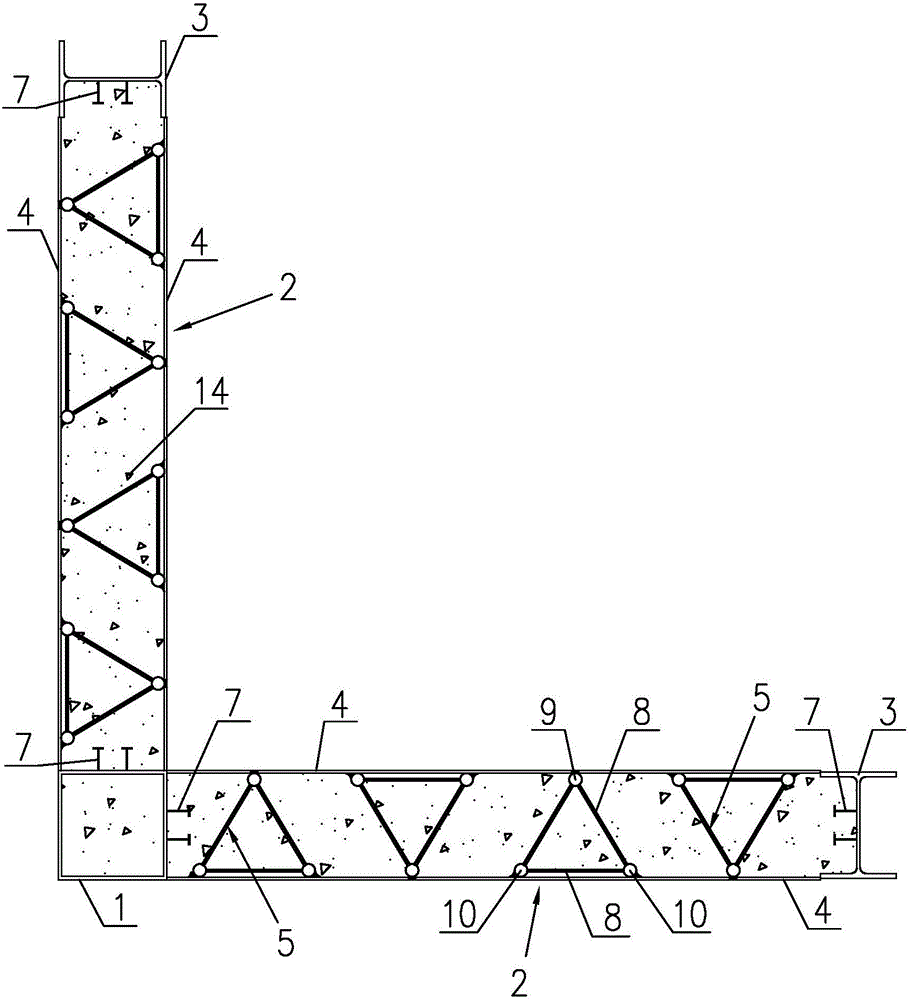

Built-in truss combined structure

InactiveCN106522420AImprove energy consumptionGood mechanical propertiesWallsEngineeringMechanical property

The invention discloses a built-in truss combined structure which comprises a combined body. The combined body is composed of steel plates and end columns. A cavity is formed among the end columns and the steel plates. Trusses are arranged in the cavity and fixed to the steel plates in a welded mode. Each truss comprises web members and chord members, wherein the chord members are fixed to the corresponding steel plates in a welded mode. Shear resisting components are arranged on the inner sides of the end columns. Concrete is poured in the cavity. The trusses and the shear resisting components are all arranged in the concrete. According to the built-in truss combined structure, advantages of steel and the concrete are fully achieved, and the structure has an excellent energy-dissipating capacity and a good mechanical property; the trusses are fixed to the steel plates in the welded mode, the steel plates on the two sides are restrained through the trusses, and premature occurrence of local buckling of the steel plates in the construction and use stage is prevented; and meanwhile, the cavity formed by the end columns and the steel plates can serve as a template for concrete pouring, and the construction cost is lowered.

Owner:浙江中南绿建科技集团有限公司

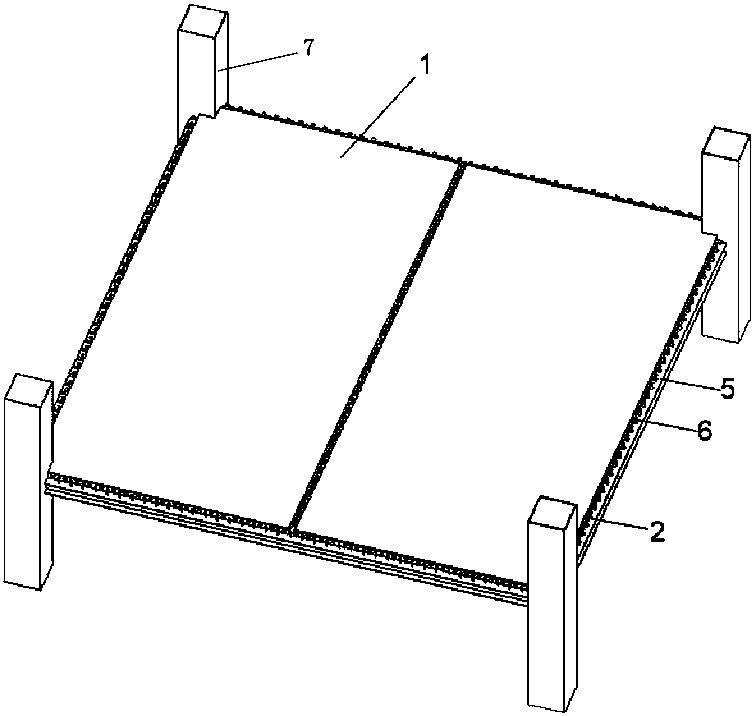

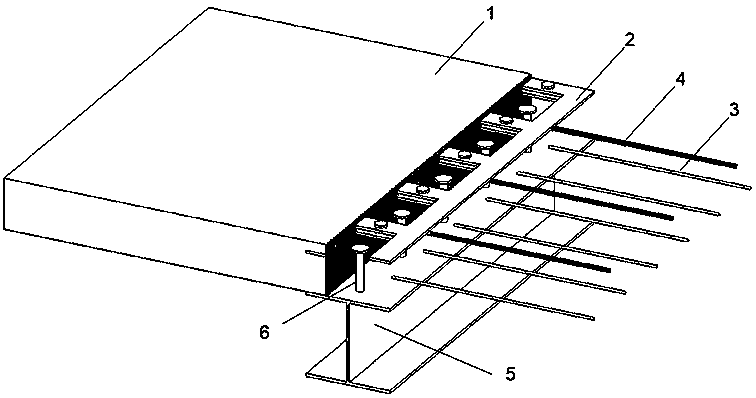

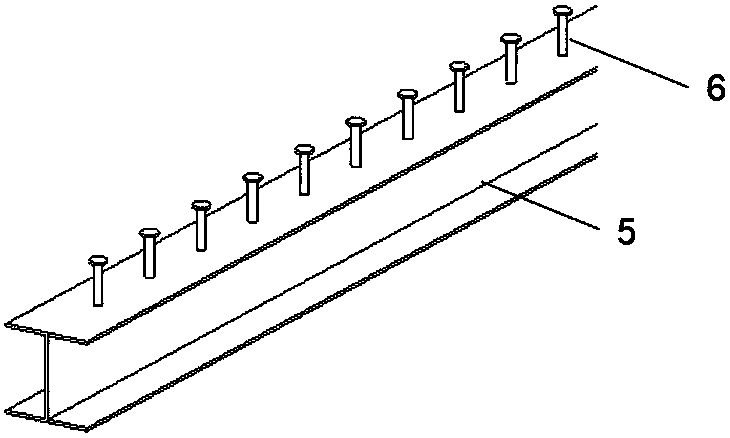

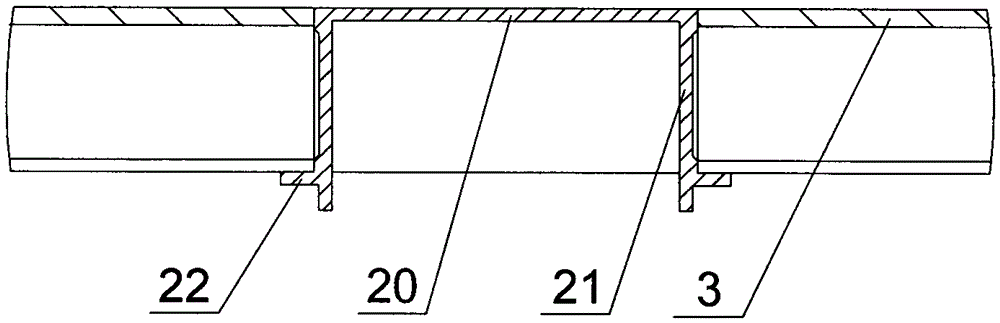

Prefabricated-type steel-profiled steel sheet concrete combined beam

The invention discloses a prefabricated-type steel-profiled steel sheet concrete combined beam, which employs steel structure columns or steel-concrete combined columns for supporting. The combined beam includes prefabricated composition boards, stubble steel plates, steel bars on the plate bottom, and a steel beam. An anti-shear connection member is welded to the steel beam. The steel beam is connected with the steel structure columns or steel-concrete combined columns to form a framework structure. The prefabricated composition boards are placed on the steel beam, wherein the stubble steel plates are pre-embedded in four sides of the prefabricated composition boards. Hogging moment steel bars are bidirectionally pre-embedded in the top part of the prefabricated composition boards. In theprefabricated composition boards, the stubble steel plates are welded to the jogging moment vertical-forced steel bars. In adjacent prefabricated composition boards, the stubble steel plates are fixed via bolts. Concrete on the top zone of the steel beam is poured in site, thus forming the complete steel-profiled steel sheet concrete combined beam. The product is low in in-site working load, canachieve non-supporting construction, is high in construction speed and construction quality, and is low in construction operation difficulty.

Owner:SHENYANG JIANZHU UNIVERSITY

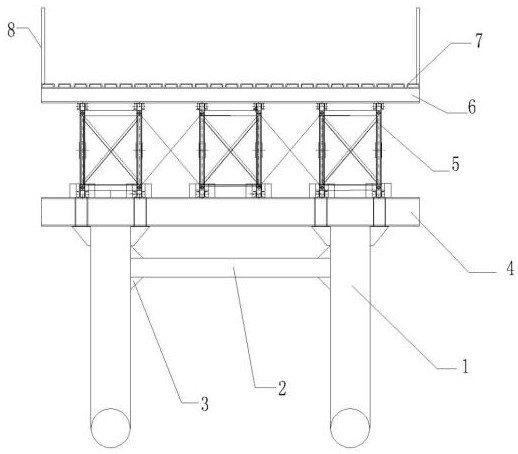

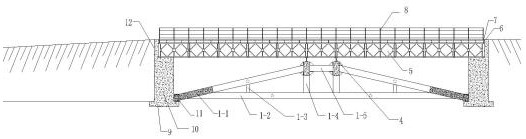

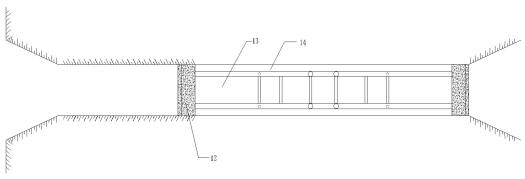

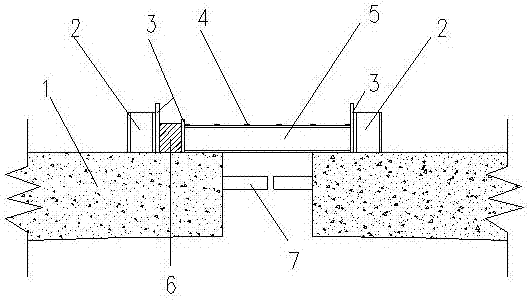

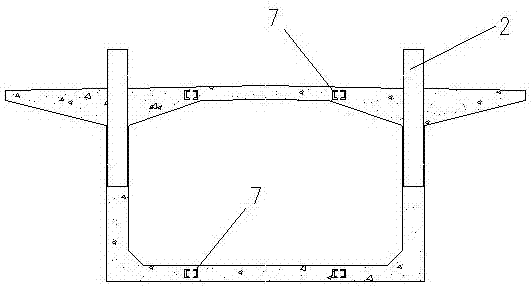

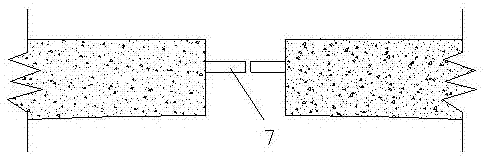

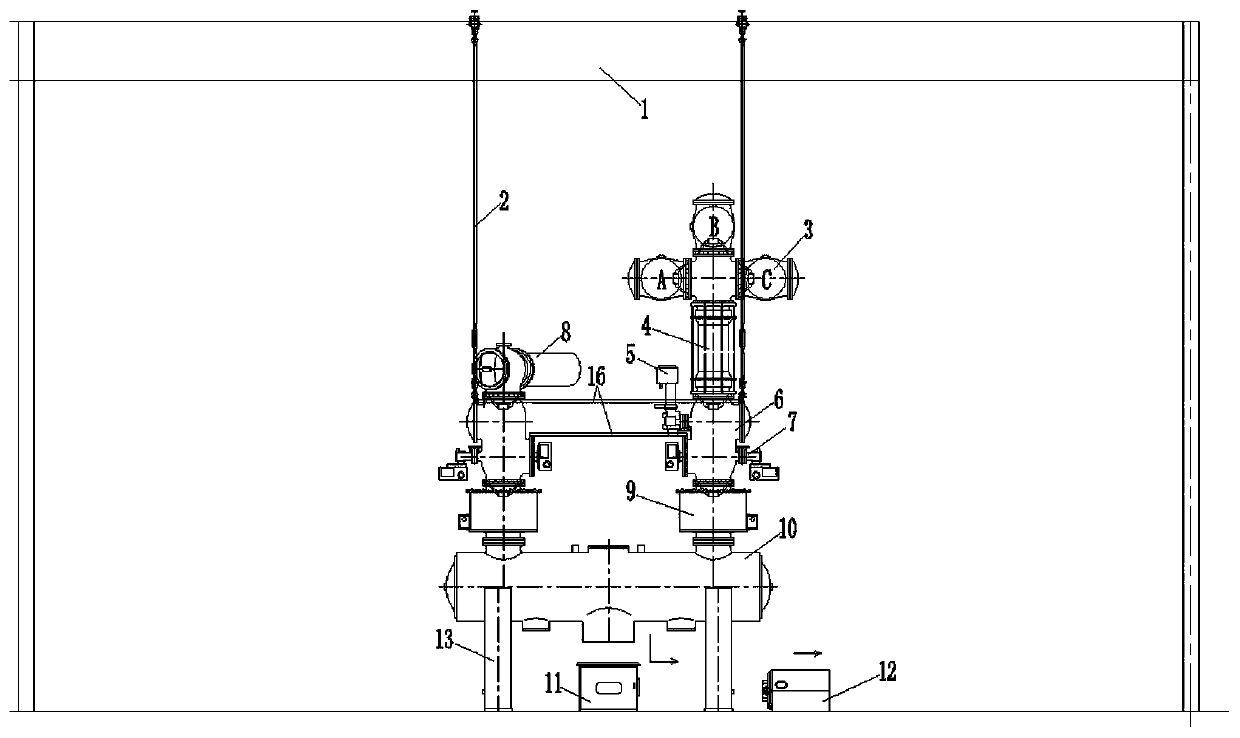

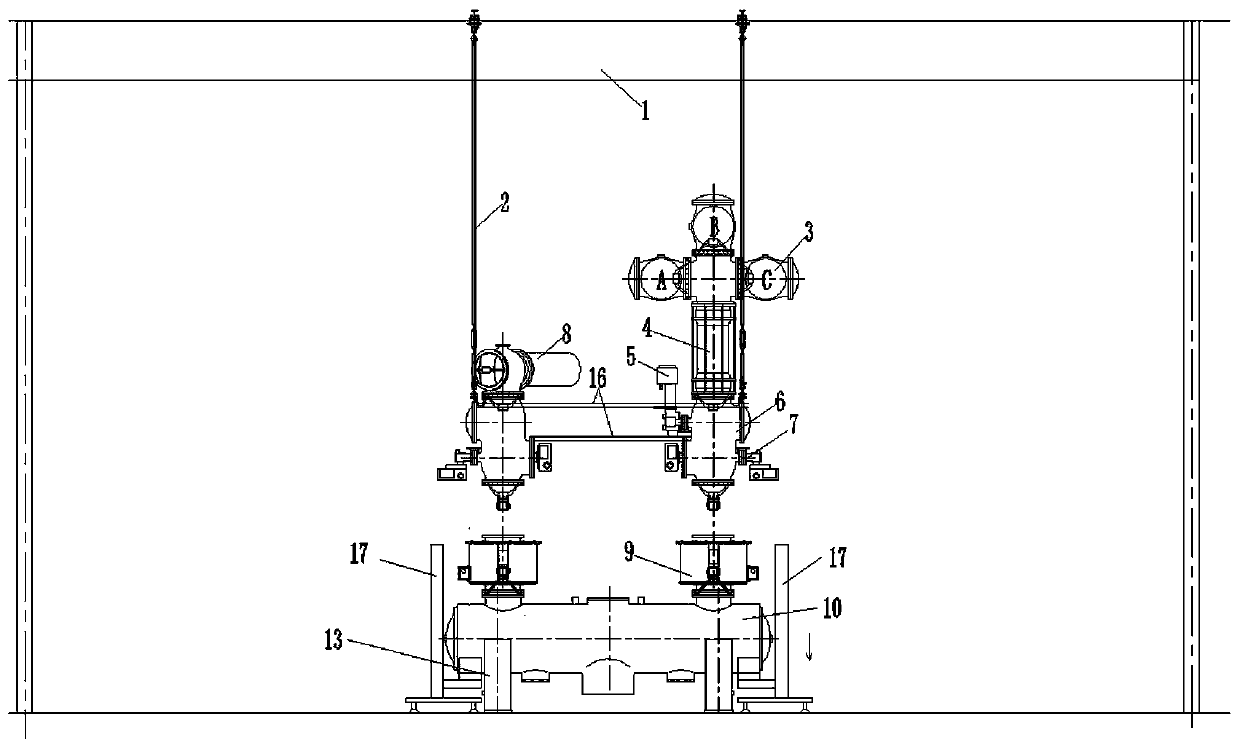

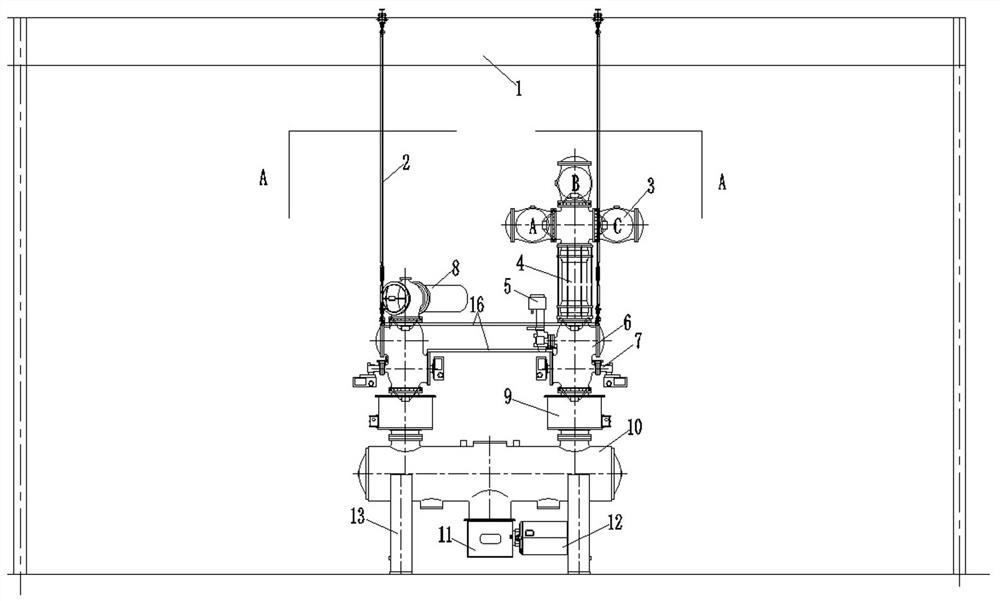

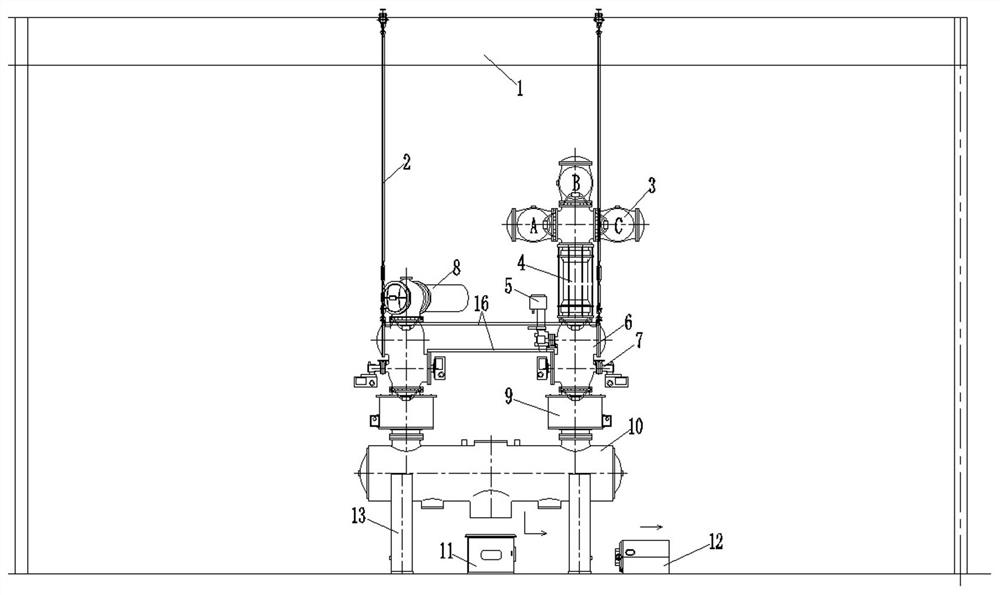

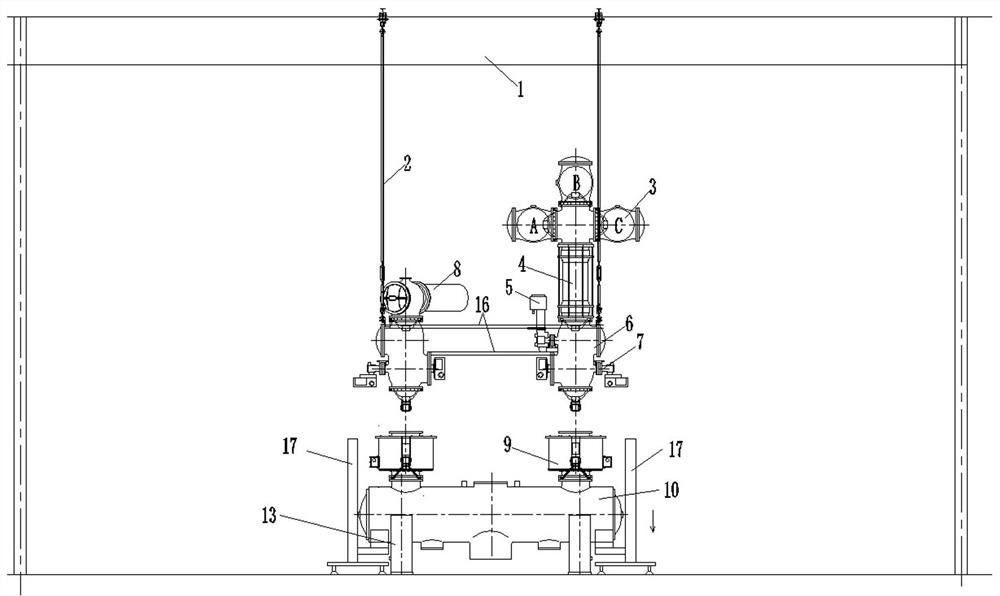

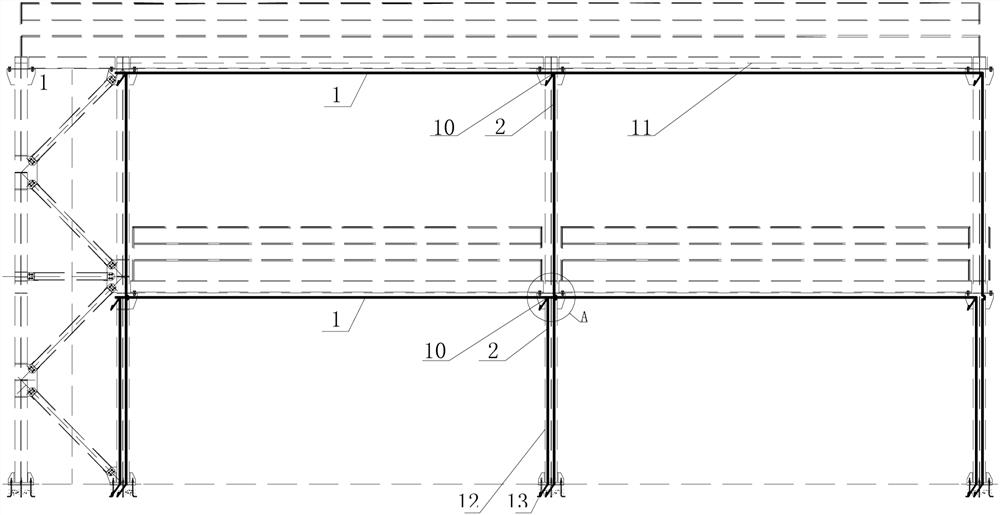

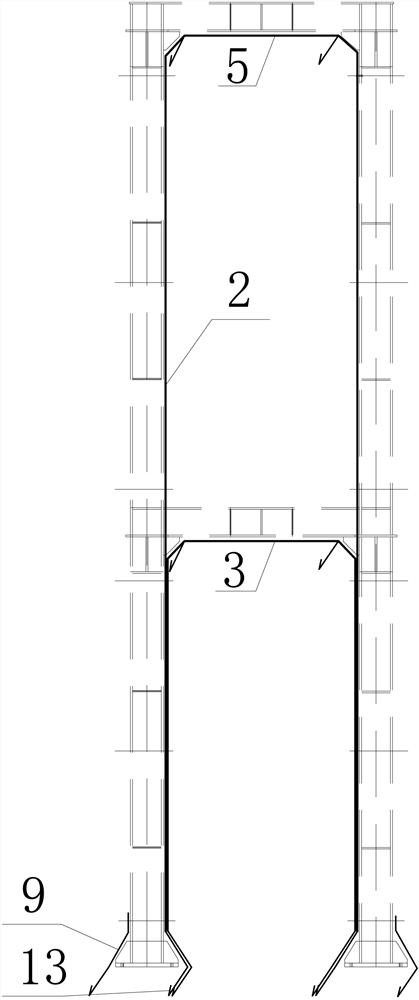

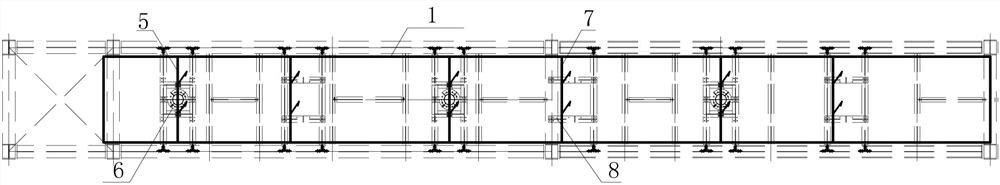

Span-free middle stand column steel trestle structure, pushing installation device and construction method

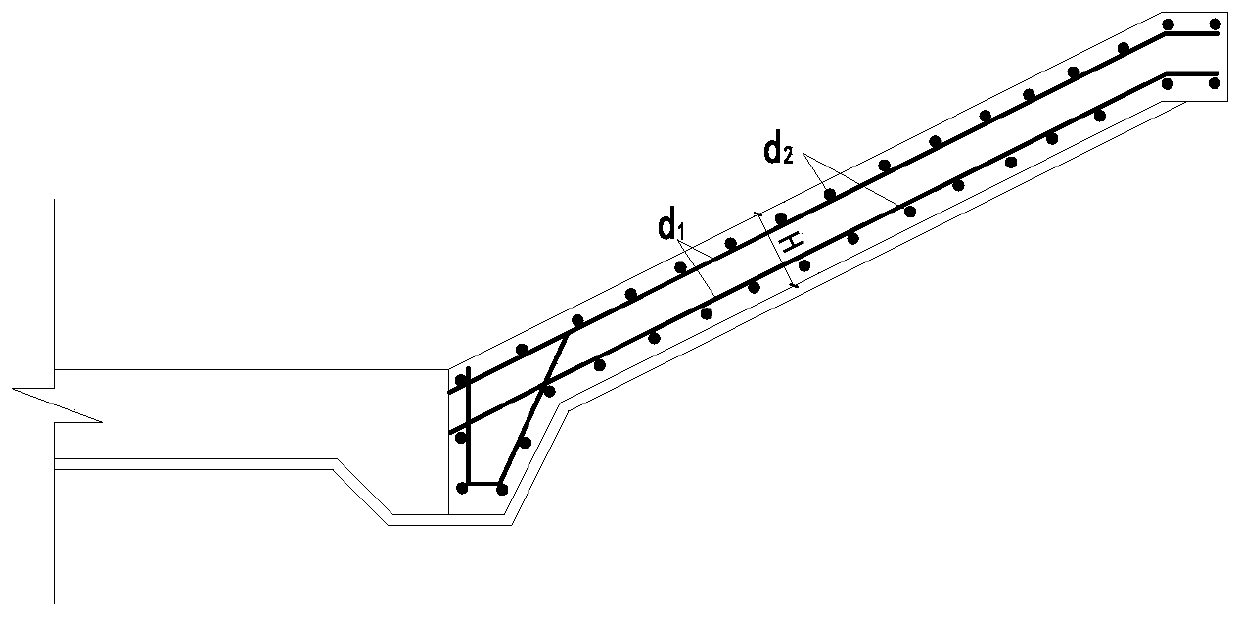

PendingCN112267369ALow costReduce the difficulty of construction operationsBridge structural detailsBridge erection/assemblyBridge deckStringer

According to a span-free middle stand column steel trestle structure, a pushing installation device and a construction method, the pushing installation device is used for pushing to complete construction of the steel trestle, convenience and rapidness are achieved, the construction difficulty is reduced, and the steel trestle structure adapts to the environment that a riverway planting soil layeris thin and pebbles exist at the river bottom; the steel trestle structure comprises a trestle abutment, a trestle support, a bearing beam, a longitudinal beam, a distribution beam and a bridge deck slab, the trestle support comprises two sets of trapezoidal steel pipe supports, each steel pipe support comprises two inclined rods, a main vertical rod, an auxiliary vertical rod, an upper horizontalrod and a lower horizontal rod, and the bearing beam is arranged above the upper horizontal rod in the transverse bridge direction. The longitudinal beams are arranged above the bearing beams in thelongitudinal direction, the two ends of each longitudinal beam are arranged on the table body, the ends of each longitudinal beam are limited and fixed through the back wall, the multiple distributionbeams are arranged above the longitudinal beams in the transverse bridge direction, the bridge deck slabs are arranged above the distribution beams, and the inclined rods, the main vertical rods, theauxiliary vertical rods, the horizontal rods and the transverse rods are connected in a welded mode. And the main vertical rod is connected with the bearing beam through a bracket.

Owner:THE THIRD ENG CO LTD OF CCCC SECOND HIGHWAY ENG BUREAU

Large tank installing method

ActiveCN110077963ASmall footprintReduce the difficulty of operationLoad-engaging elementsSafety coefficientEngineering

The invention relates to a large tank installing method. The large tank installing method comprises the installing steps that at least two winches are arranged on an uppermost-layer workshop platformthrough which a to-be-installed tank is about to penetrate, and the winches are symmetrically arranged on the two sides of a to-be-installed position of the tank; then, traction ropes of the winches penetrate through stress points and then are downwards released to arrive at the ground; the to-be-installed tank is segmented from top to bottom to be hoisted; a hoisting lug is welded to each of thetwo side walls of a first-section tank body located at the top end, a tackle is used for fixing a section of steel wire rope to the corresponding hoisting lug, then, the steel wire rope is connected with the traction ropes of the winches, and hoisting is started; and after each section of tank body is hoisted, the opposite opening positions of every two adjacent sections of tank bodies are welded.An existing platform in a workshop is utilized for installing work, the advantages that hoisting work can be conducted without usage of a crane, the occupied field area is small, production is not influenced, operation difficulty is low, and the safety coefficient is high are achieved, and the large tank installing method is worthy of being popularized and applied to metallurgy construction projects.

Owner:CHINA MCC20 GRP CORP +1

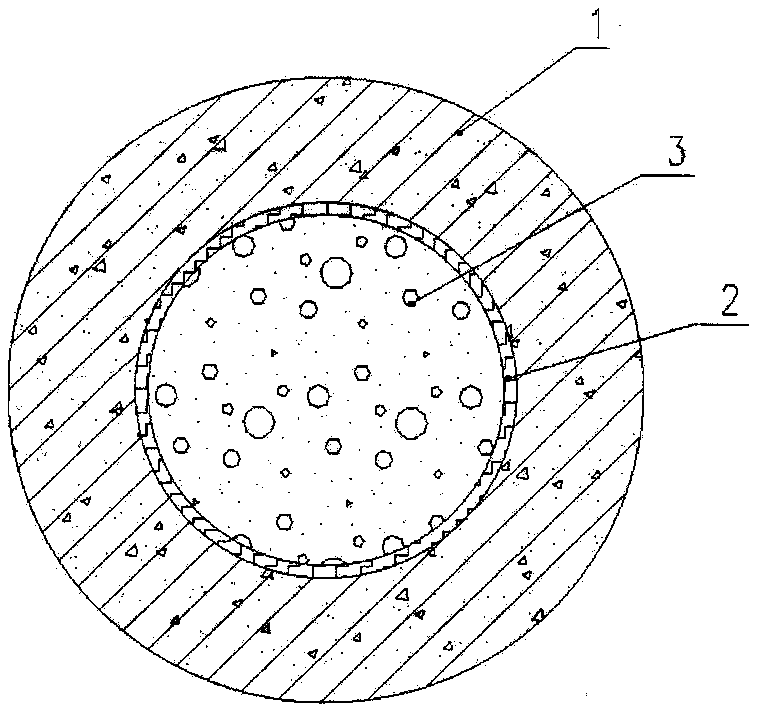

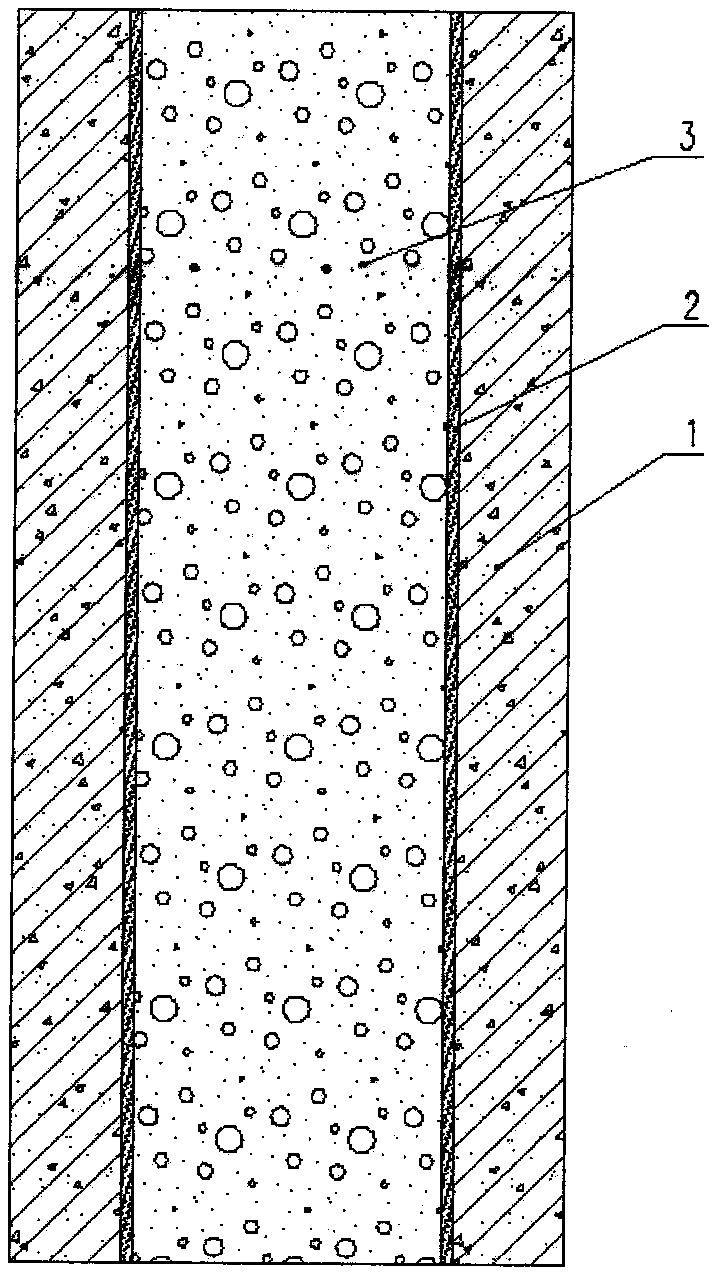

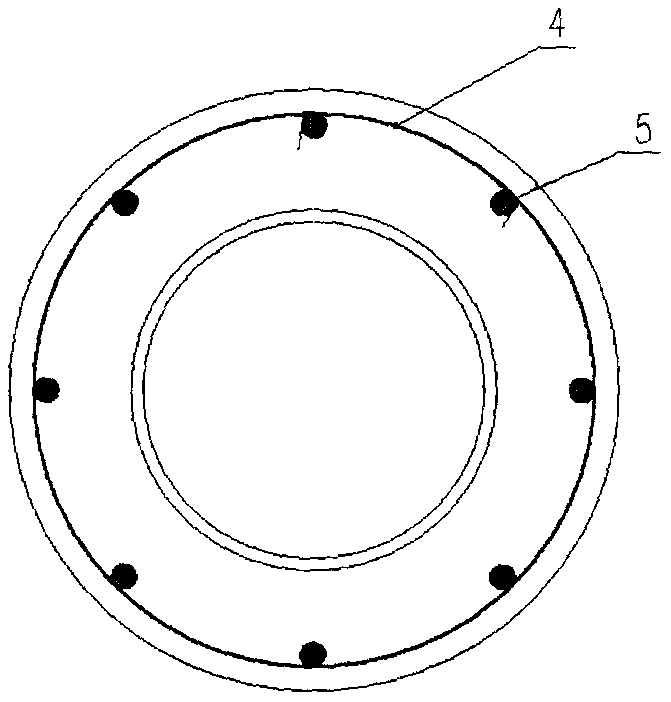

Heat insulation pipe shell for LNG (liquefied natural gas) filling station pipeline

InactiveCN104100806AExcellent ruggedness and reliabilityClose contactThermal insulationPipe protection by thermal insulationThermal energyWave shape

The invention discloses a heat insulation pipe shell for an LNG (liquefied natural gas) filling station pipeline. The heat insulation pipe shell for the LNG filling station pipeline comprises a pipe shell body which is of a hollow cylindrical structure; the pipe shell body comprises two half shells which are of consistent structures; the inner surface of each half shell is in wave-shaped arrangement in the axial direction; grooves are formed in the outside ends of the two end surfaces of each half shell; the heat insulation pipe shell also comprises filling strips; the filling strips are of strip-shaped structures which are matched with the grooves in the same side of the two half shells and are in the same sizes as those of the two grooves; locking rings are arranged on the outer surfaces of the filling strips and are connected with rope pieces used for fixedly connecting the two half shells. The heat insulation pipe shell for the LNG filling station pipeline has the beneficial effects that the structure is simple, the operation is convenient, the practicability is high, more heat can be locked and prevented from dissipating, and the heat is insulated effectively; moreover, the radiating area of the heat insulation pipe shell and a conveying pipeline is small, so that high-efficiency heat insulation is further guaranteed; meanwhile, the heat insulation pipe shell for the LNG filling station pipeline is assembled and disassembled conveniently and quickly; the construction operation difficulty is low; the firmness and the reliability are high; the production cost of the heat insulation pipe shell is also low.

Owner:ZHANGJIAGANG SHUNJIA INSULATION TECH

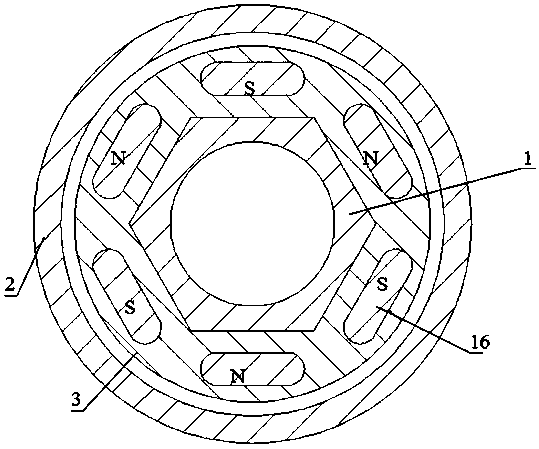

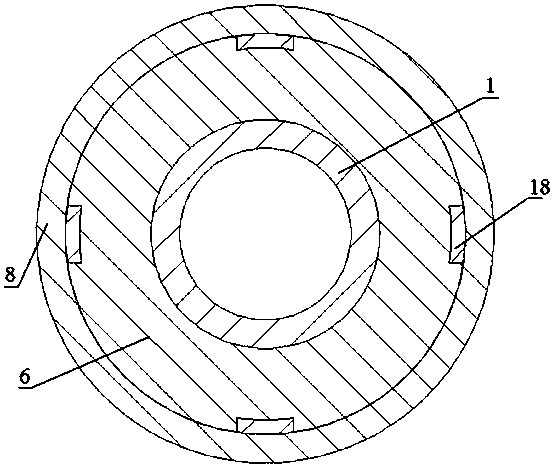

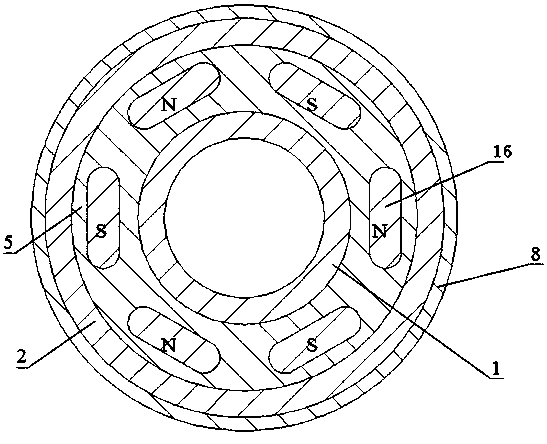

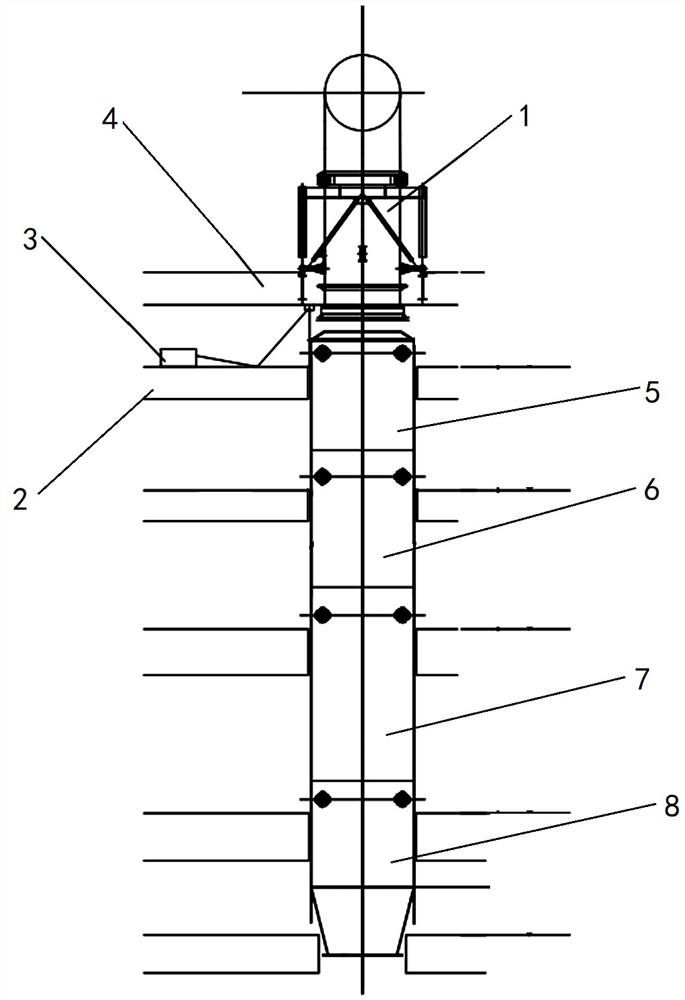

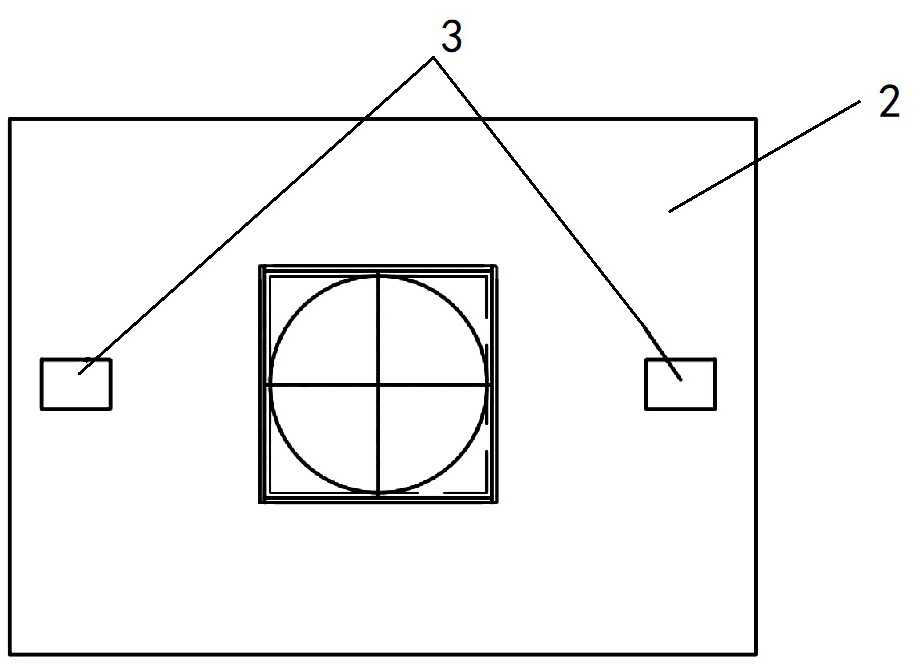

Downhole rotary impact tool based on magnetic force and method

PendingCN108252650AExtended service lifeImprove rock breaking efficiencyBorehole drivesCemented carbideEngineering

The invention relates to a downhole rotary impact tool based on magnetic force and a method. According to the technical scheme, a tool outer barrel is arranged on the outer side of a transmission center shaft, an upper magnetic ring is arranged on the upper transmission center shaft, the upper magnetic ring is fixedly connected with the upper transmission center shaft through a limiting bearing and a thrust bearing. The lower part of the thrust bearing is provided with a spring base. The spring base is connected with the upper end of an auxiliary spring. The lower end of the auxiliary spring is connected with a lower magnetic ring. The lower magnetic ring is fixedly connected with a cemented carbide shaft sleeve. A lower transmission center shaft is arranged at the lower part of the uppertransmission center shaft. The downhole rotary impact tool based on magnetic force and the method have the beneficial effects that the tool is simple in structure, easy to achieve and small in construction operation difficulty, downhole application is improved, a magnetic control impact mechanism is introduced, non-contact arrangement of the impact function can be realized, and the service life ofthe impact mechanism is greatly prolonged.

Owner:SINOPEC SSC +3

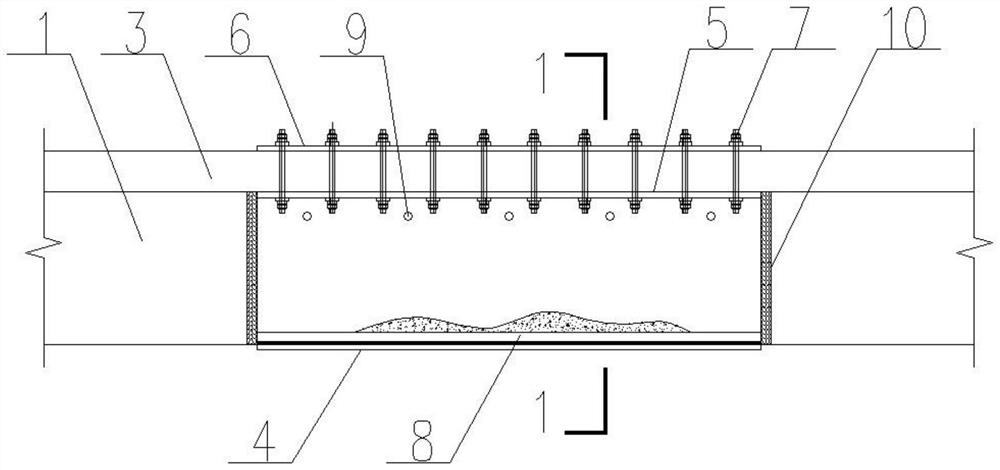

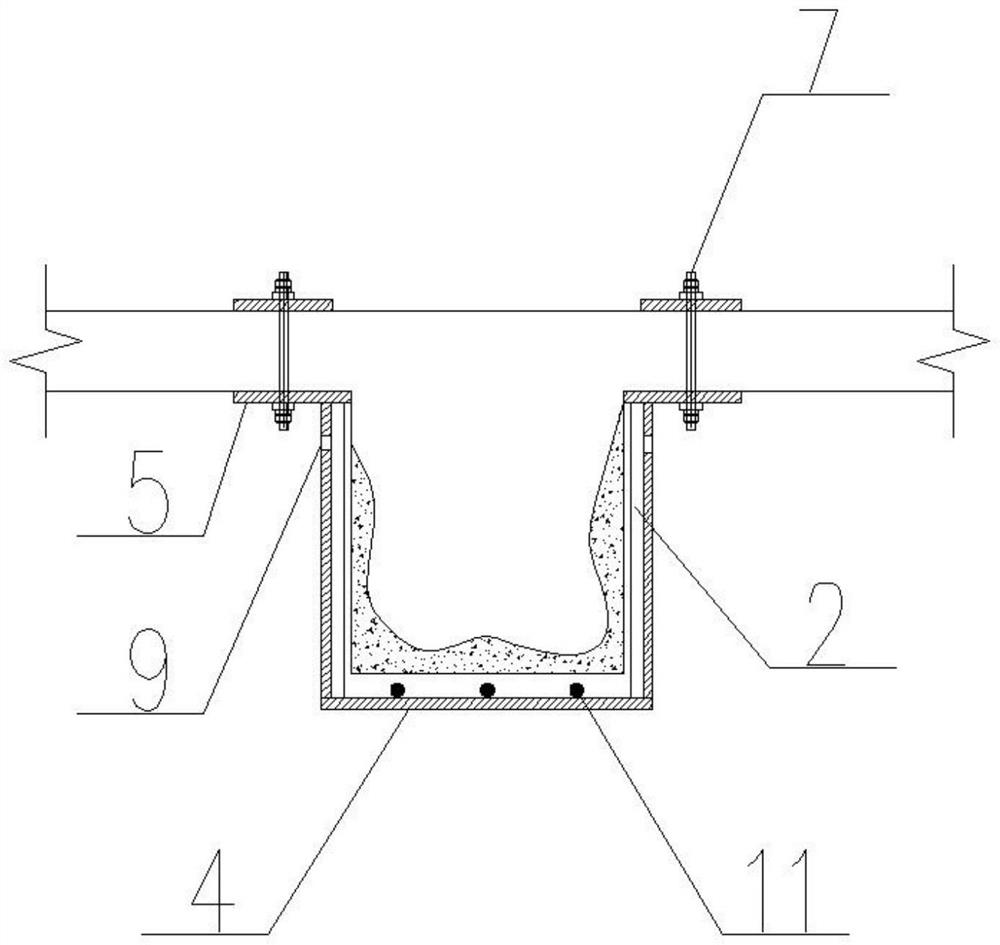

Concrete beam repairing structure and repairing method applicable to same

PendingCN114541799ARealize local defect repairHigh strengthBuilding repairsGirdersConcrete beamsArchitectural engineering

The invention provides a concrete beam repairing structure and a repairing method suitable for the concrete beam repairing structure, and belongs to the technical field of building structures. The device comprises a concrete beam, a U-shaped steel plate, plate bottom anchoring steel plates and plate top anchoring steel plates, a concrete plate is connected to the upper portion of the concrete beam, the U-shaped steel plate sleeves the outer surface of the concrete beam, a grouting layer is formed between the U-shaped steel plate and the concrete beam, and the plate bottom anchoring steel plates are arranged on the bottom surfaces of the concrete plate on the two sides of the concrete beam. The U-shaped steel plate is arranged above the concrete plate, the plate bottom anchoring steel plate is connected with the edge of an opening of the U-shaped steel plate in a welded mode, the plate top anchoring steel plate and the plate bottom anchoring steel plate are correspondingly arranged above the concrete plate, and the plate top anchoring steel plate and the plate bottom anchoring steel plate are fixedly connected through a plurality of opposite-pull screws which are evenly arranged at intervals. And the section strength and rigidity of the beam are enhanced.

Owner:上海民航新时代机场设计研究院有限公司

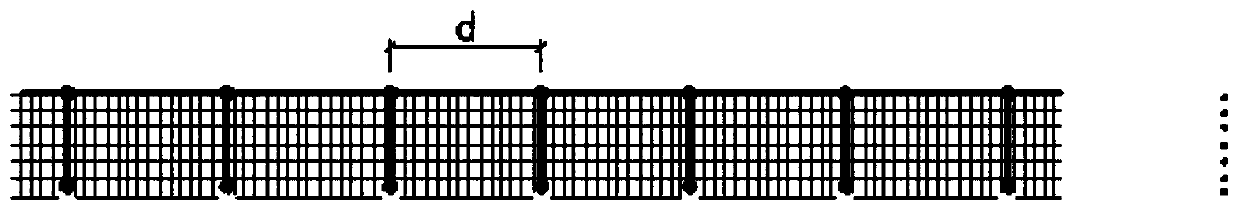

Large-angle high-thickness slope surface concrete pouring graded grid

The invention discloses a large-angle high-thickness slope surface concrete pouring graded grid. The large-angle high-thickness slope surface concrete pouring graded grid is composed of meshes and a supporting mounting system; the supporting mounting system is paved along the slope surface, and galvanized electrowelding steel wire gauze is adopted in the meshes; and the width of the graded grid isslope surface concrete thickness minus the thickness of an upper protective layer and a lower protective layer and the diameter of an upper layer of steel bars and a lower layer of the steel bars, aninterval of the meshes placing is determined through the galvanized steel wire mesh theory maximum ash blocking quantity water level and a perpendicular distance from a slope surface intersection tothe meshes, so that the meshes better block ash, and the concrete slope slipping phenomenon is controlled. According to a field slope surface structure, the limitation of concrete pouring slump limitand the pouring procedure of concrete, the concrete is poured in two layers, and vertical partition meshes are arranged and pouring is carried out by dividing left and right parts of each layer. Whenthe concrete is poured, pouring phenomena of large area and high pressure do not exist, and the slope surface is stable. The problems of increased operating personnel operating quantity, slow construction speed, low efficiency, prolonged construction period and the like are solved.

Owner:BEIJING TIANHENG CONSTR

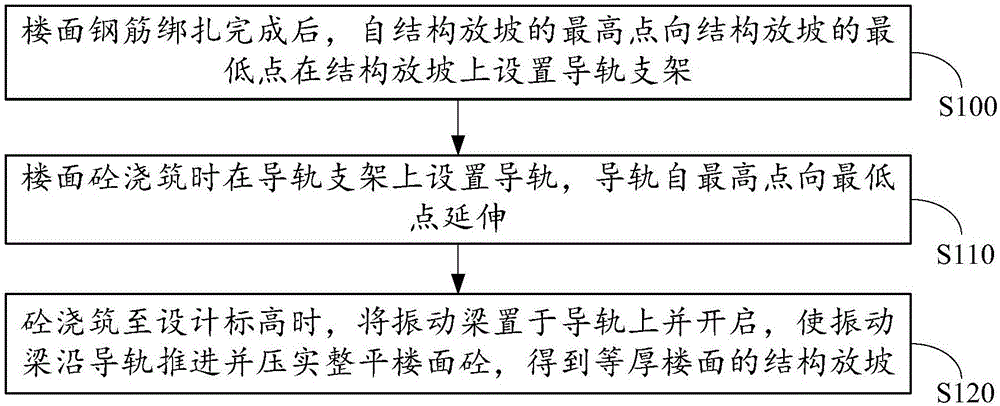

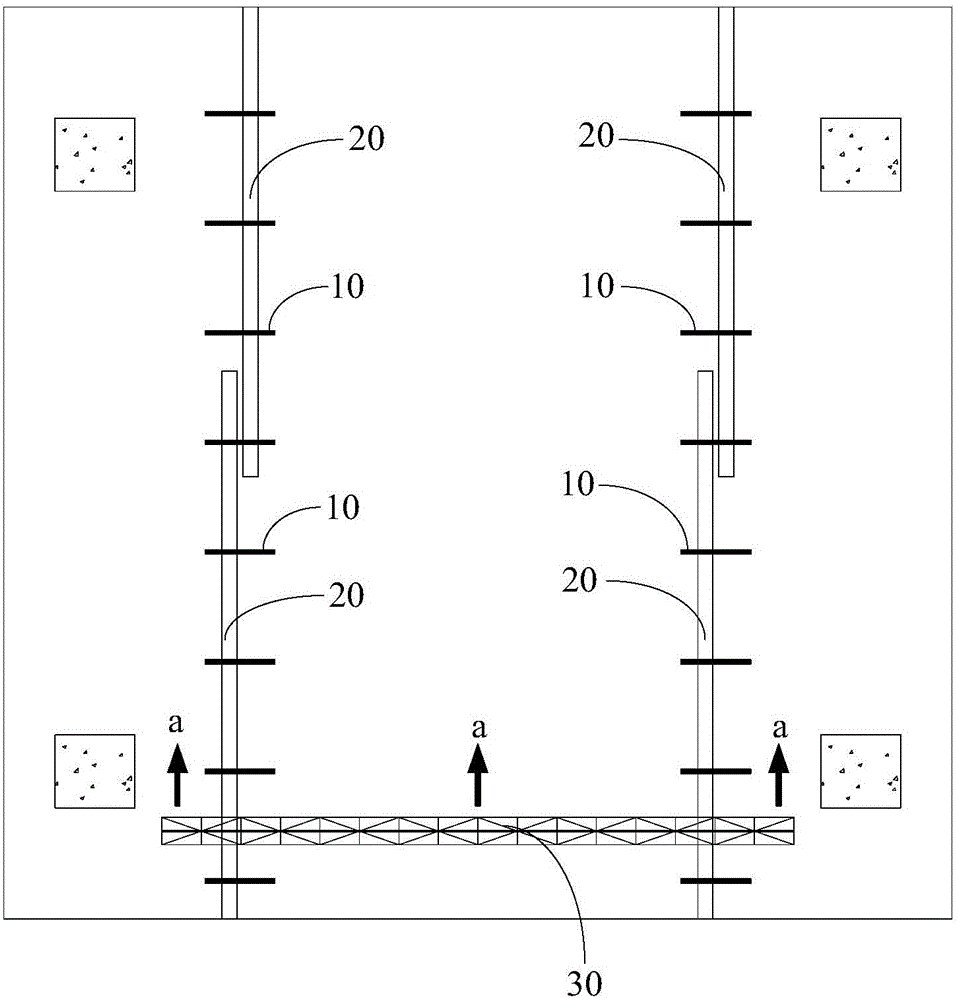

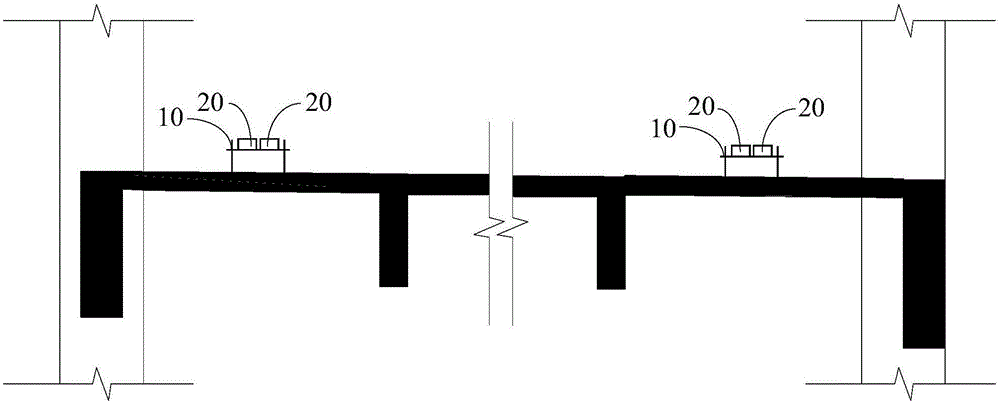

Control method for equal-thickness floor level of structural reserved slope

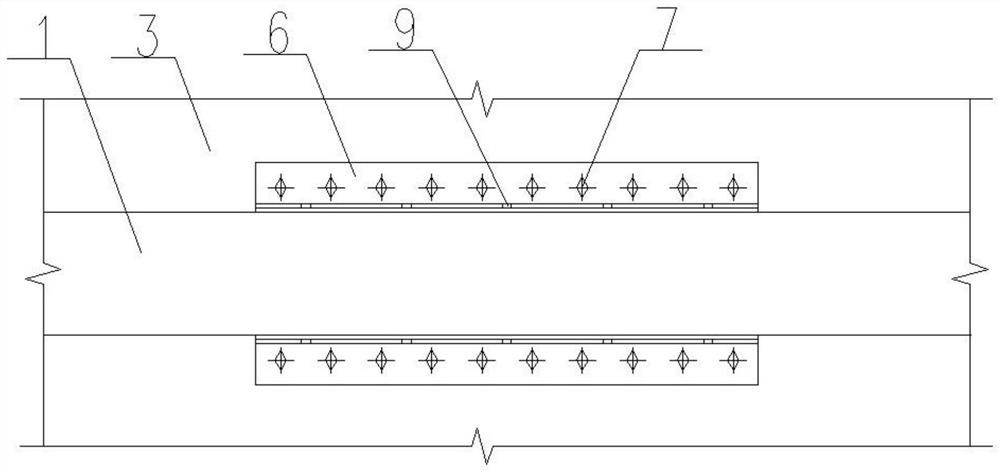

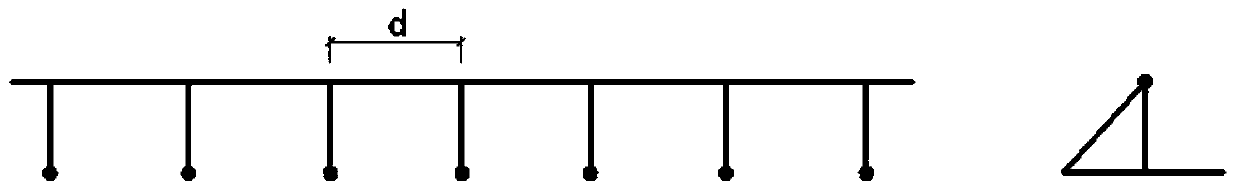

InactiveCN106836814AEasy to controlReduce the difficulty of construction operationsBuilding material handlingEngineeringRebar

The invention relates to a control method for the equal-thickness floor level of a structural reserved slope. The control method comprises the steps that after floor steel bar binding is completed, guide rail brackets are arranged on the structural reserved slope from the highest point of the structural reserved slope to the lowest point of the structural reserved slope; during floor concrete pouring, guide rails are arranged on the guide rail brackets and extend from the highest point to the lowest point; and when concrete is poured to a designed level, a vibration beam is arranged on the guide rails and started, so that the vibration beam advances along the guide rails and compacts and levels the floor concrete, and the structural reserved slope of an equal-thickness floor is obtained. According to the control method, every time the vibration beam advances for a section along the guide rails, pouring is conducted according to the designed level of the section, and the equal-thickness floor level of the structural reserved slope is controlled within a certain range by controlling the designed levels of different axes and controlling the smoothness through advancement of the vibration beam. The control method for the equal-thickness floor level of the structural reserved slope can easily control the floor level and is low in construction operation difficulty.

Owner:SHANGHAI NO 7 CONSTR

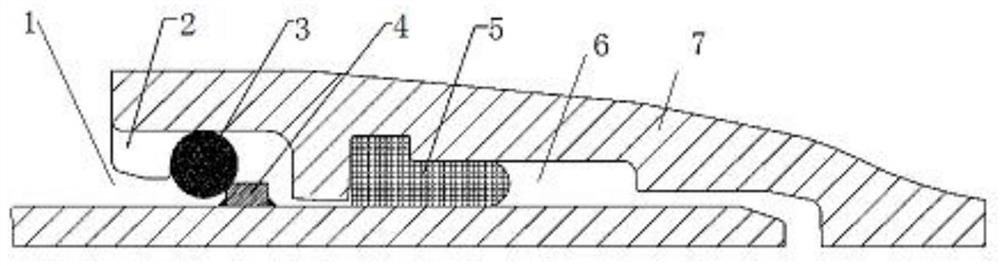

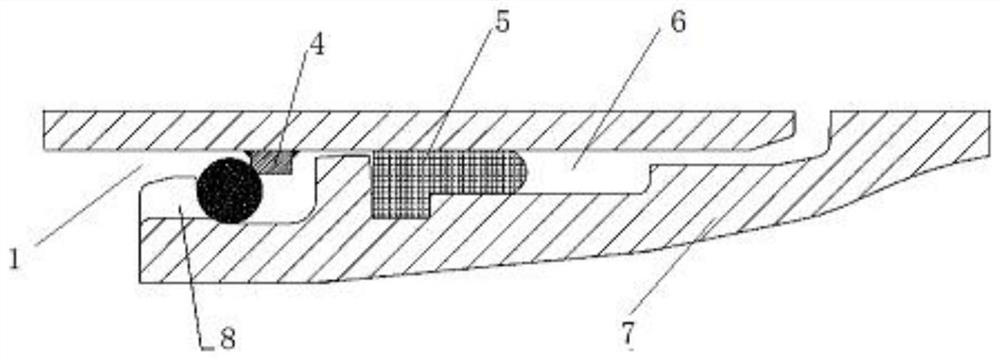

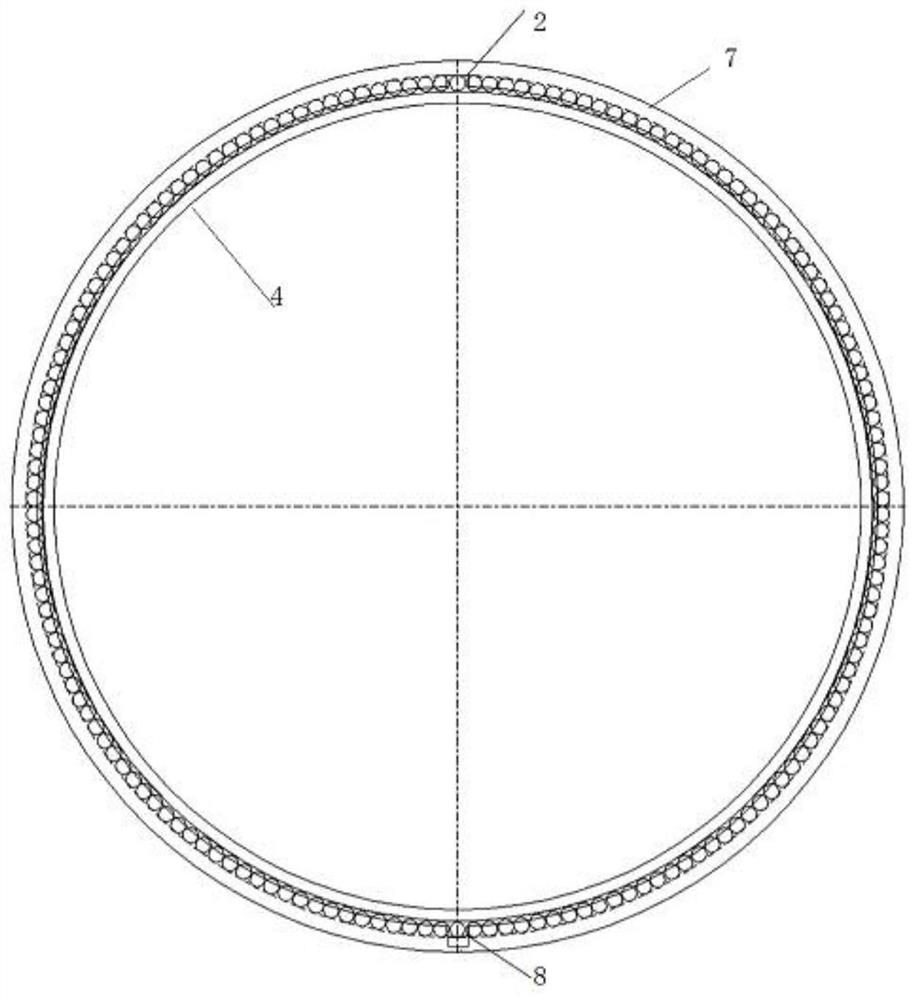

A self-anchored pipeline interface structure

ActiveCN112797240BAvoid excessive accumulationOptimize corner spaceEngine sealsCouplingsRubber ringStress concentration

A self-anchored pipeline interface structure includes a pipeline body, one end of the pipeline body is a socket end, the socket end of the connected pipeline is inserted into the socket end, and a ball installation port and a ball ball are arranged in sequence from the end face of the socket end. Groove, positioning groove, balls are installed in the ball groove, a rigid ring is arranged on the outer wall of the socket end of the connecting pipe, the ball is located in the cavity between the outer groove wall of the ball groove and the left side of the rigid ring and can be connected with the rigid ring The left corner of the ring is abutted, the positioning groove is located on the right side of the rigid ring, a sealing rubber ring is arranged inside, and the lower side of the end of the socket end opposite to the ball installation port is provided with a corresponding disassembly port, and the ball can pass through the disassembly port After unloading, the rigid ring is welded on the outer wall of the socket end of the connecting pipe. The part to be welded is preferably provided with a chamfer or a welding groove capable of accommodating solder, and preferably a force component groove is formed at the left corner of the rigid ring. The invention further simplifies the operation, unblocks the ball sliding channel, reduces the stress concentration after assembly, and comprehensively improves the construction efficiency and the self-locking and anti-separation sealing effect.

Owner:SHANDONG GUOMING DUCTILE IRON PIPES TECH CO LTD

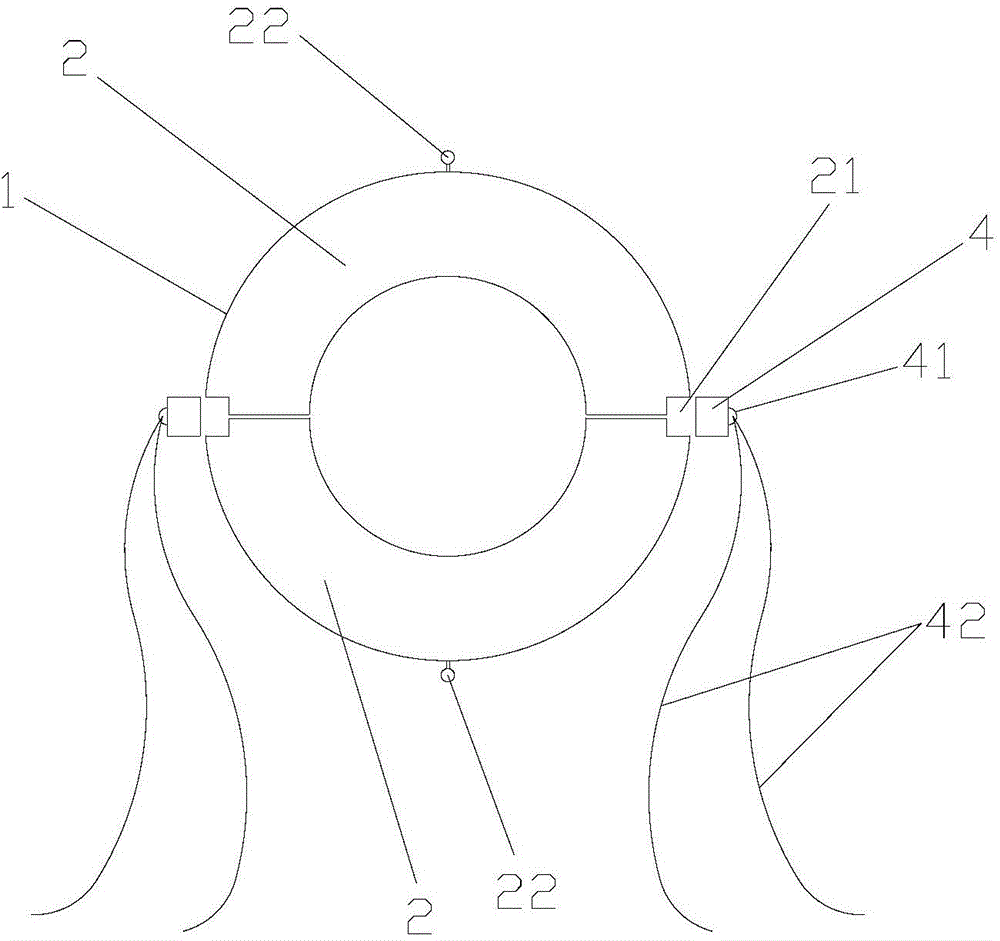

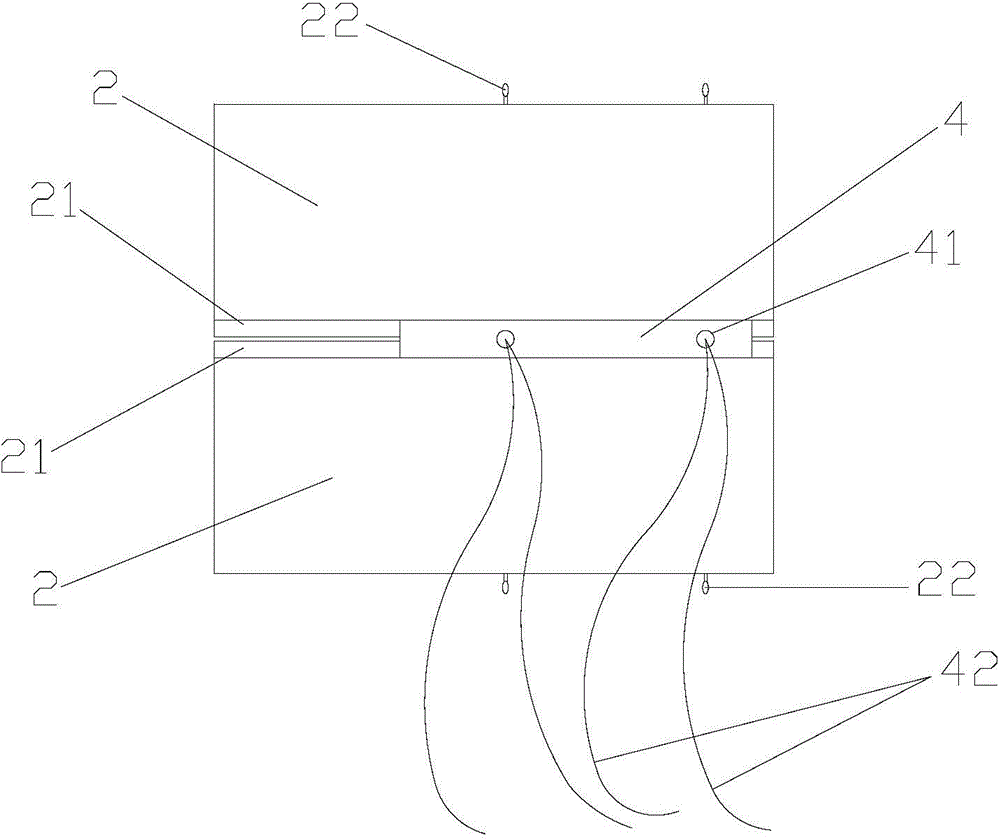

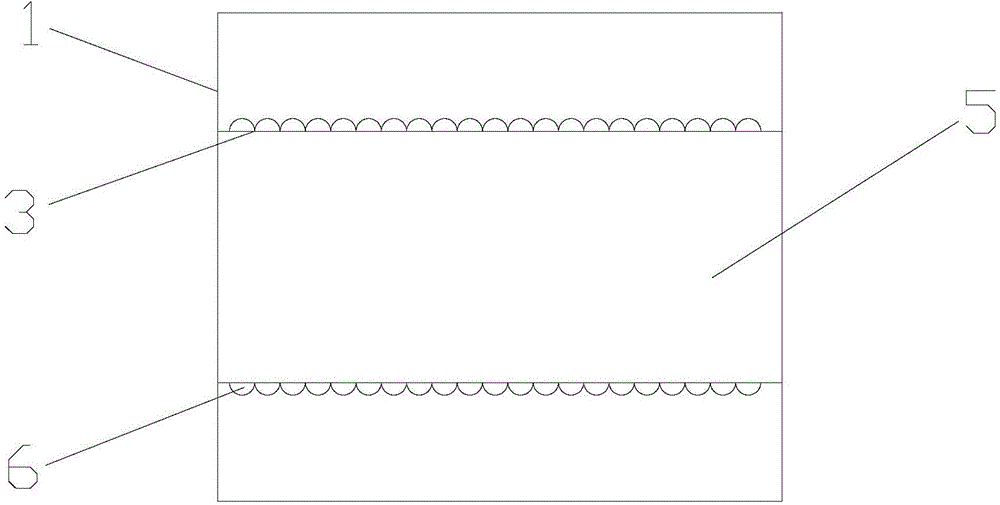

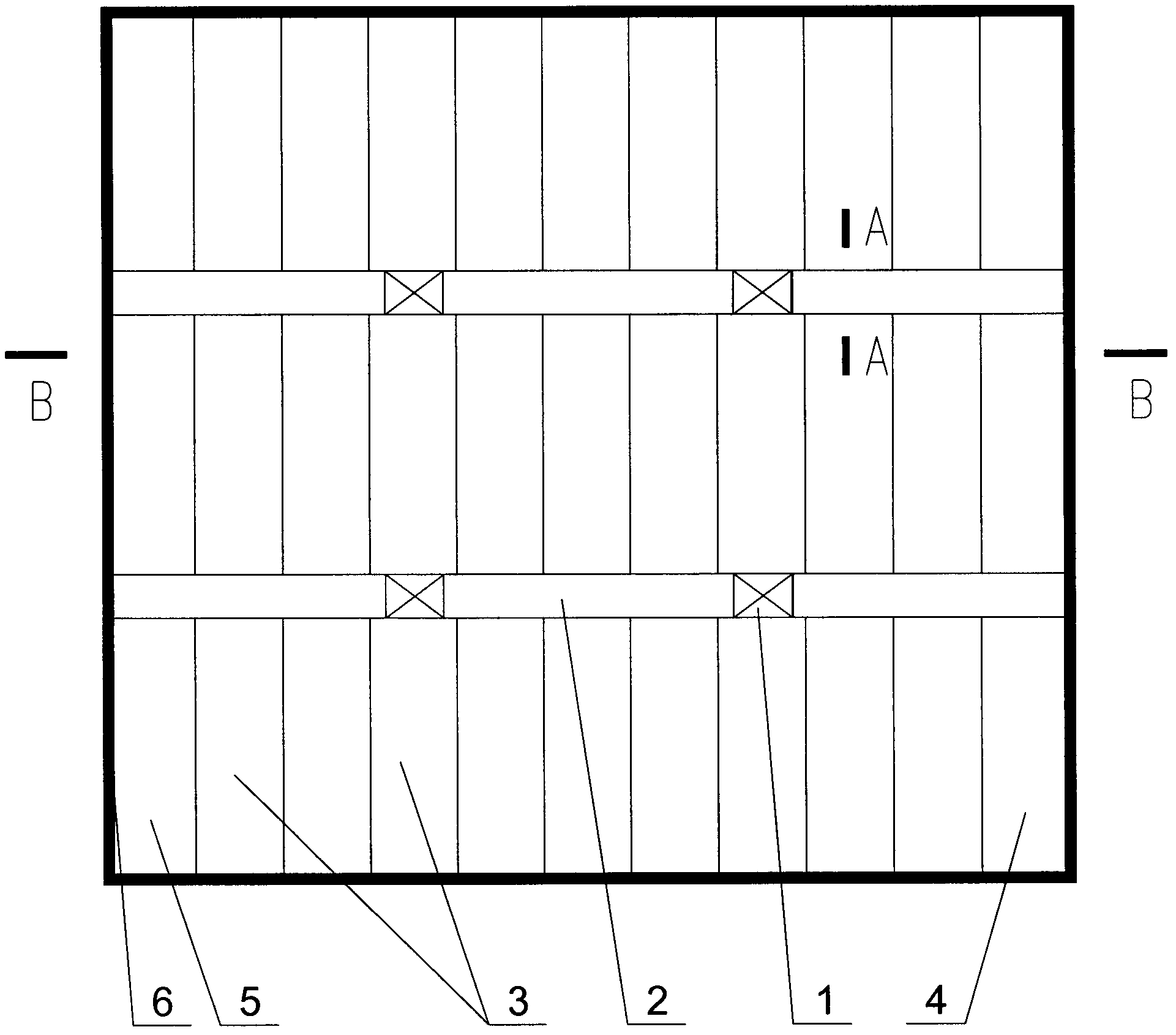

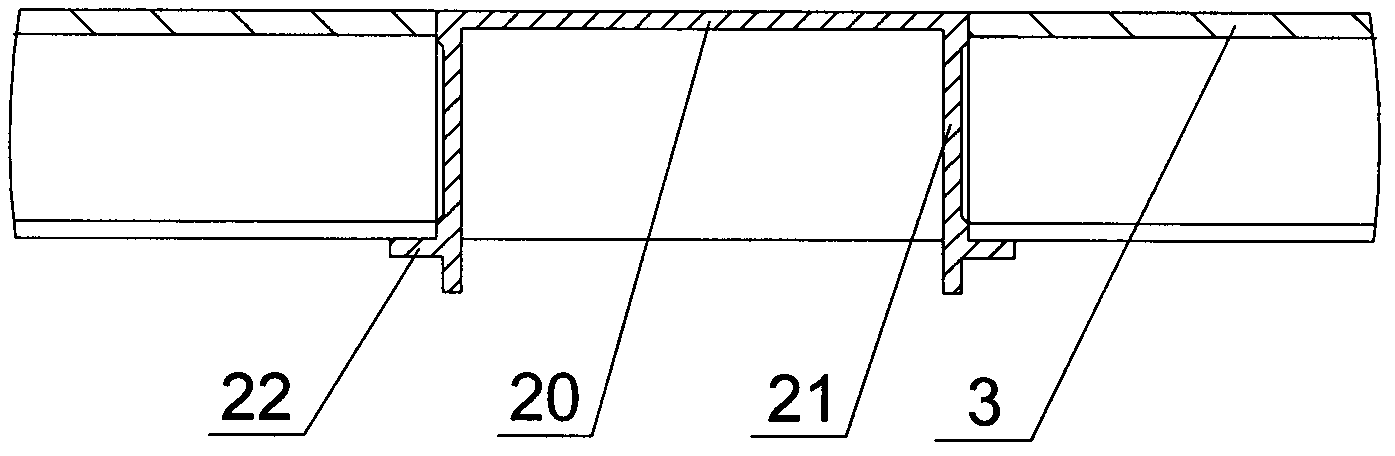

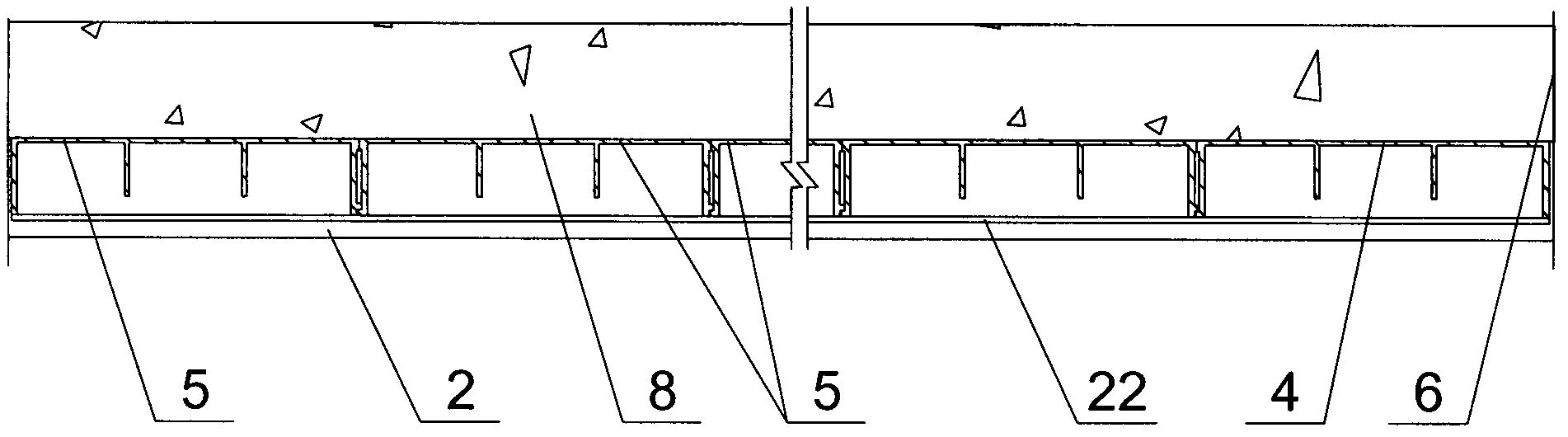

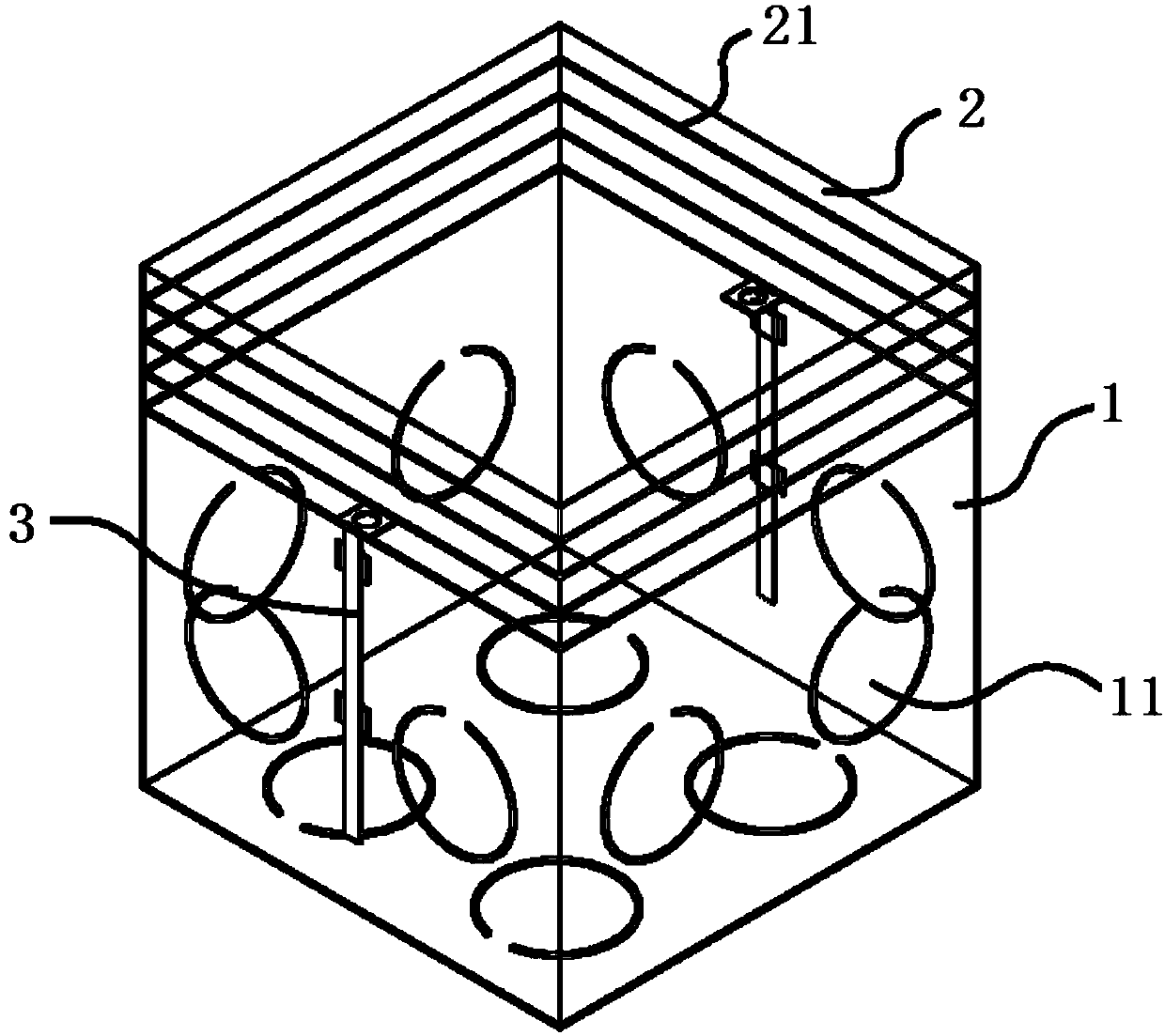

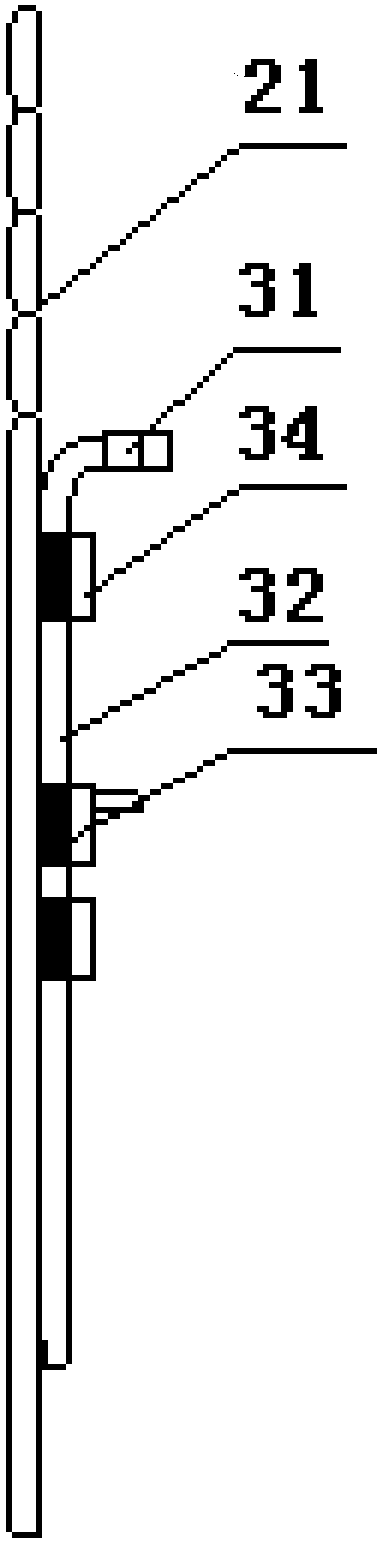

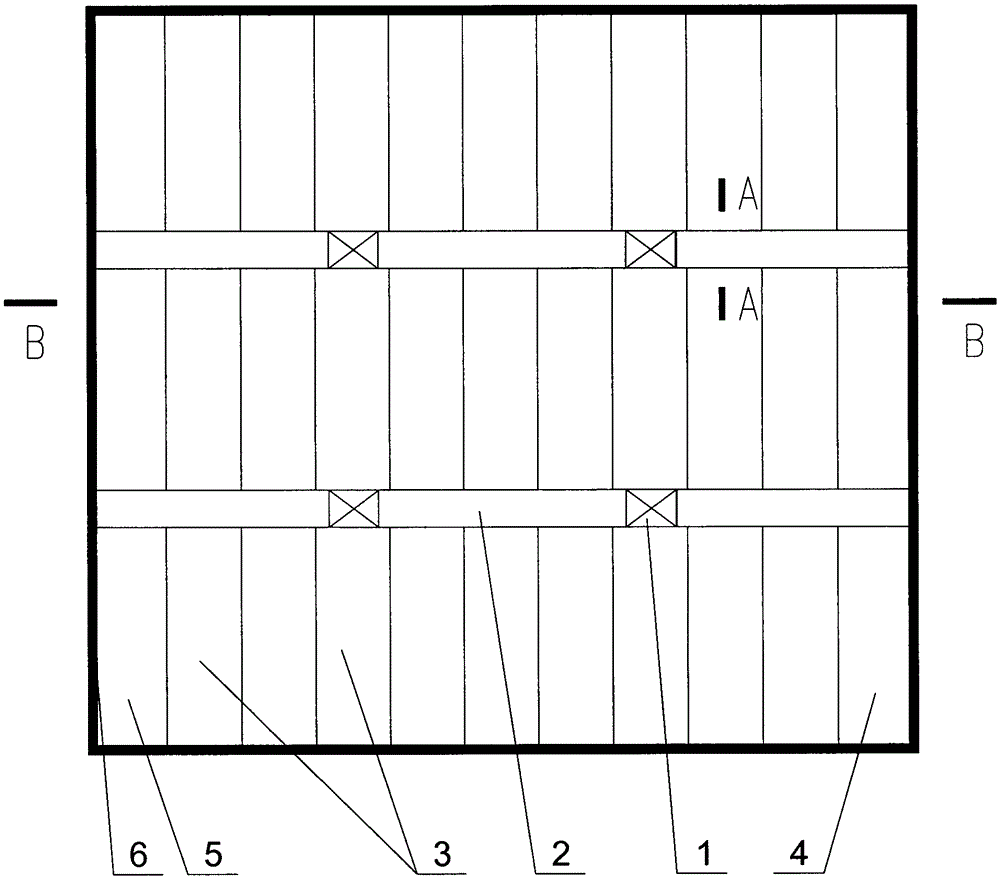

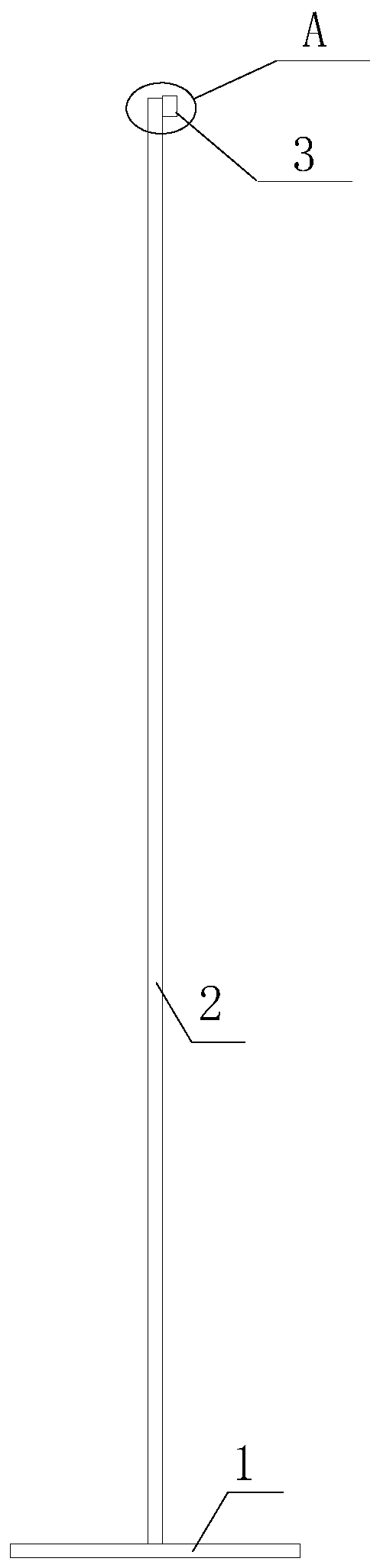

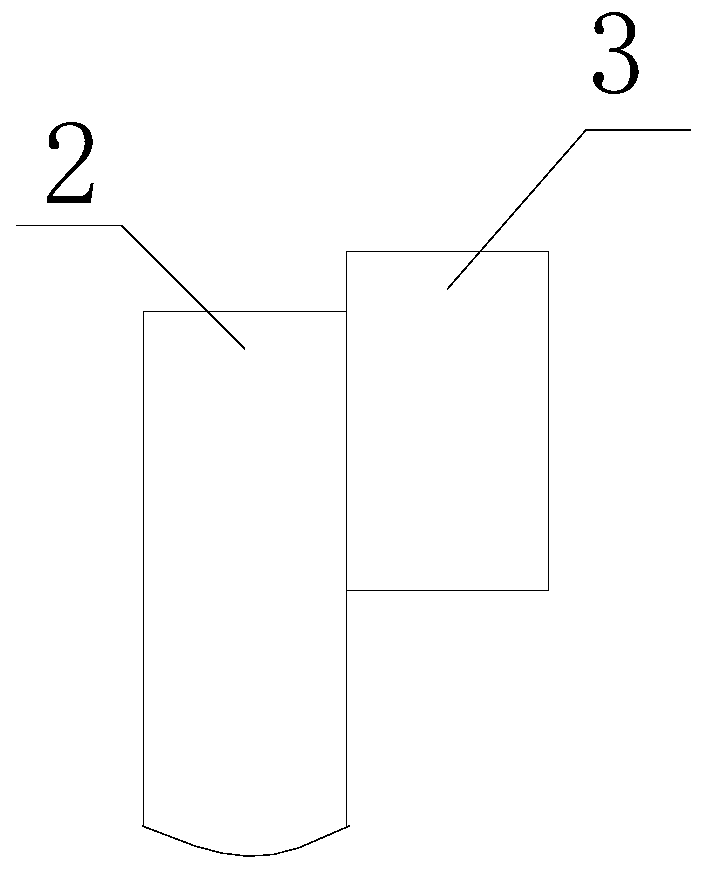

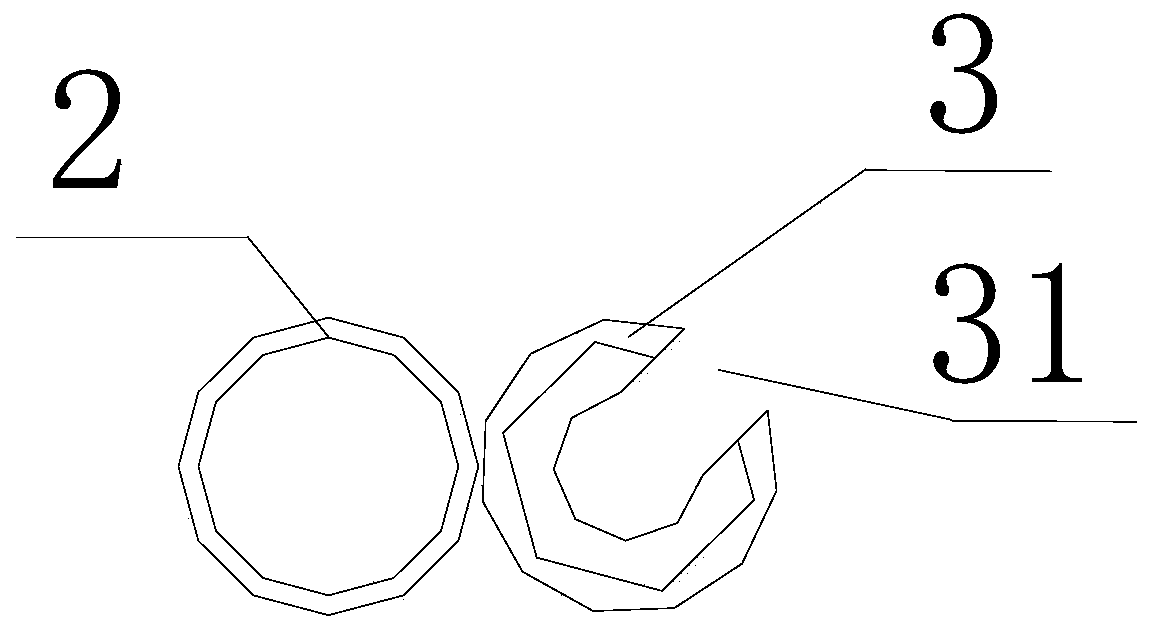

Bilateral self-bearing building template system

ActiveCN103216087AReduce distortionImprove the uniformity of forceForms/shuttering/falseworksBuilding constructionMental detachment

The invention discloses a bilateral self-bearing building template system, which has the advantages of material saving, high construction efficiency, good bearing effect and long service life. The system further has the advantages of no pin connection, difficulty in deformation, capabilities of increasing the turnover use efficiency and reducing processing and installing workloads, convenience in early detachment, easiness and convenience in operating, practicability, effective increase in the seam density of a template and improvement on the concrete forming effect. The system comprises support column assemblies (1), bearing beams (2) and bearing plates (3), wherein the bearing beams (2) are connected with the support column assemblies (1) to construct a plurality of single-direction main beams; the bearing plates (3) are distributed among the single-direction main beams, and construct a template system plate surface together with the single-direction main beams; beam lugs (22) are arranged on the lower parts of the side faces (21) of the bearing beams (2); the two ends of the bearing plates (3) are overlapped on the beam lugs (22); two side plates (31, 32) of the bearing plates are provided with plate lugs (311, 321); adjacent bearing plates (3) are matched and overlapped through the plate lugs (311, 321); and the top plates (30) of the bearing plates (3) are flush with the top surfaces (20) of the bearing beams (2). The system can be applied to the field of building templates.

Owner:FOSHAN GUANGYA ALUMINUM FORMWORK SCI & TECH

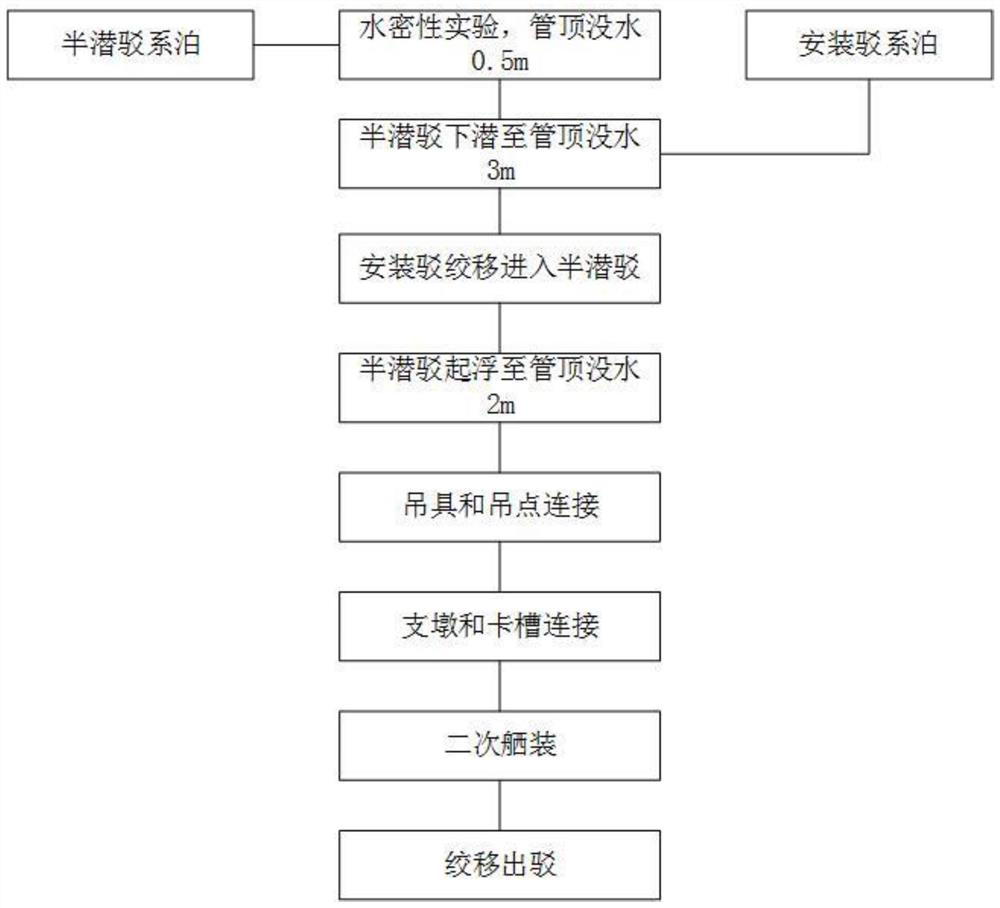

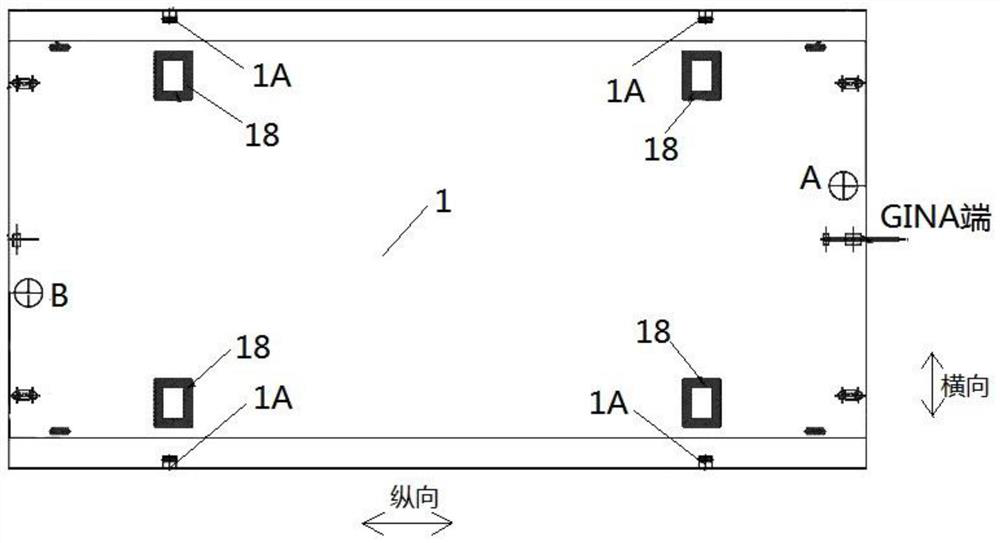

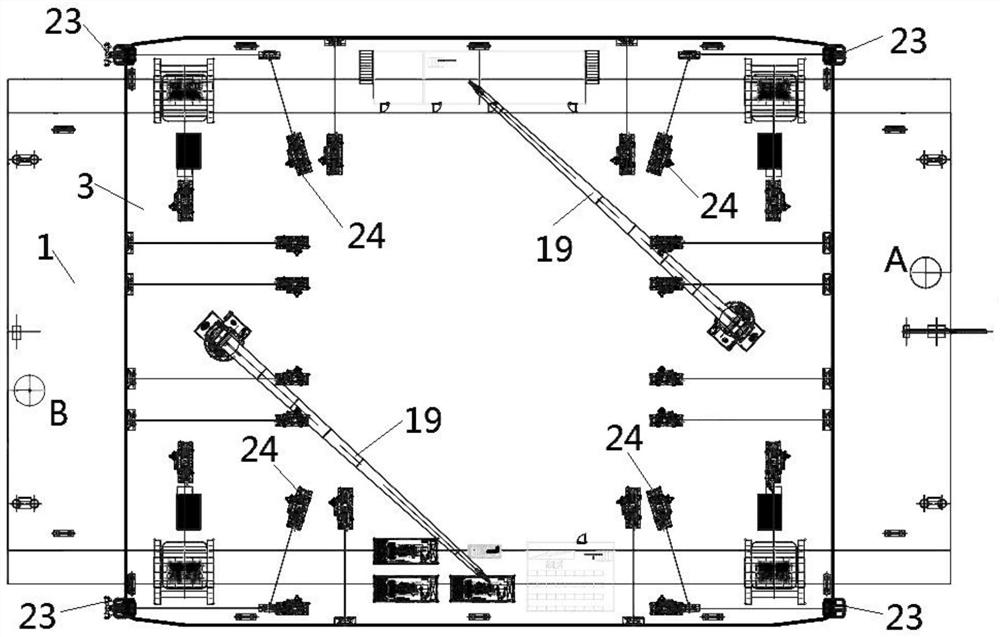

Barging-out method for non-self-floating immersed tube

ActiveCN113879487ARealize unloading / unloadingThe process is simple and fastArtificial islandsSlipwaysEngineeringImmersed tube

The invention relates to the technical field of immersed tube tunnels, in particular to a barging-out method for a non-self-floating immersed tube. The method comprises the following steps of: submerging the non-self-floating immersed tube along with a semi-submersible barge, twisting and moving a mounting barge to sleeve the non-self-floating immersed tube and then butting the mounting barge with the non-self-floating immersed tube, performing secondary fitting-out operation, providing hoisting force for the non-self-floating immersed tube by using the mounting barge, and then driving the non-self-floating immersed tube to realize barging-out through the twisting and moving mounting barge. Thus, safe barging-out of the non-self-floating immersed tube which cannot automatically float is realized, and a working procedure is simple and rapid. Compared with a traditional mode that the self-floating immersed tube is directly twisted and moved out of a barge, the invention has the advantages that the mounting barge is twisted and moved out of the barge, a mooring winch system does not need to be arranged on the tube top of the non-self-floating immersed tube, tube top outfitting pieces are few, and outfitting operation procedures are few; and compared with a traditional mode that secondary outfitting is conducted after the tube joints of the self-floating immersed tube are unloaded, secondary outfitting operation is conducted on the semi-submersible barge before unloading, so the sequence of the secondary outfitting operation procedures is changed, and in this way, the non-self-floating immersed tube does not need to be moored again after being unloaded, and operation procedures are simplified.

Owner:CCCC FOURTH HARBOR ENG CO LTD +2

Adjustable JDG secondary structure reserved wire box

PendingCN107645148AImprove molding qualityFast constructionElectrical apparatusEngineeringPre embedding

The invention discloses an adjustable JDG secondary structure reserved wire box. The JDG secondary structure reserved wire box comprises a wire box fixing module which is in a cuboid structure with anupper opening, a multi-stage wire box adjusting module which is arranged in the upper opening of the wire box fixing module, and an adjustable screw seat. Adjoining stages of the wire box adjusting module and the wire box adjusting module and the wire box fixing module are connected through peel wires. The adjustable screw seat comprises an adjustable screw hole, a slip sheet connecting sheet, afixation lock block and a slip sheet lock. The fixation lock block is fixed on the inner side of the wire box fixing module. The slip sheet lock is pressed down to be closed with the fixation lock block to permanently lock the slip sheet connecting sheet. The JDG secondary structure reserved wire box can be arranged in place once. After plaster shut-off, an adjustment section higher than the plaster finishing surface is removed to form a beautiful pre-embedded wire box sleeve mouth. In a later period, the wire box does not need to be separately processed, which saves the labor cost.

Owner:BEIJING URBAN CONSTR NORTH CONSTR

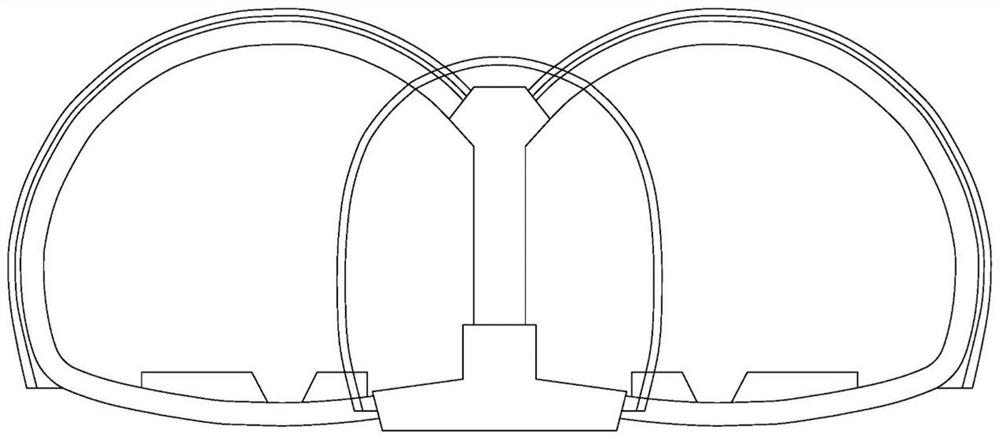

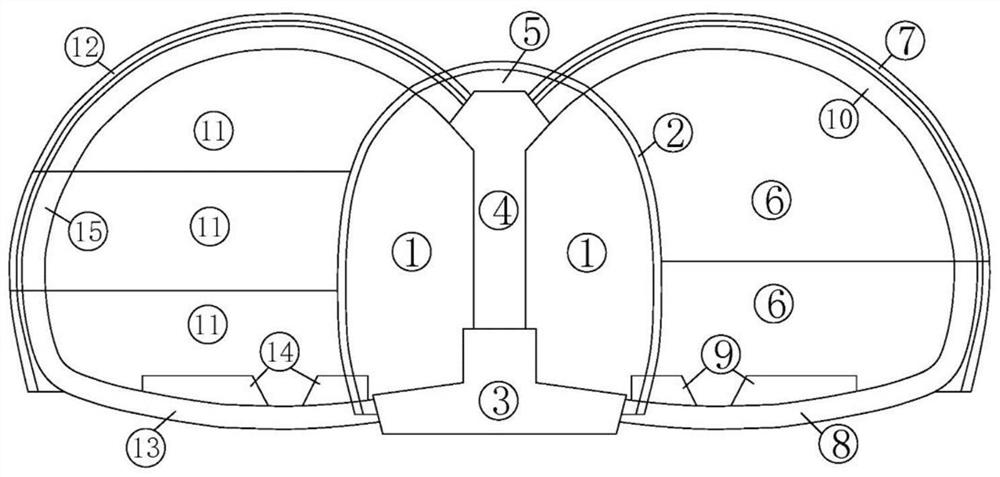

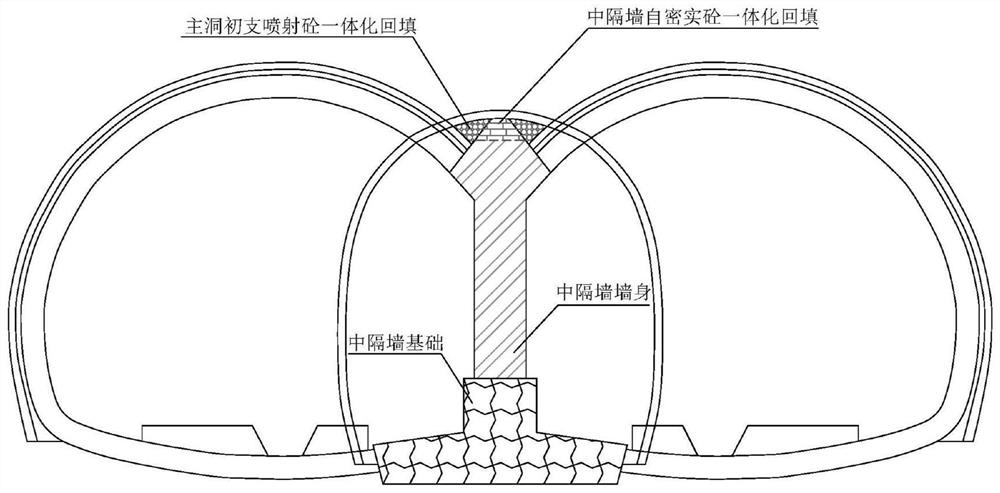

Integrated backfilling and pouring method for integral straight middle wall top of multi-arch tunnel

PendingCN113586066AAvoid vibrating without compactionAvoid intensityUnderground chambersDrainageShotcreteWater leakage

The invention discloses an integrated backfilling and pouring method for an integral straight middle wall top of a multi-arch tunnel, which is characterized in that a space between a middle partition wall top and a middle pilot tunnel initial supporting vault is divided into three areas, namely a wall top trapezoid area and triangular areas on the two sides; a middle partition wall body and a wall top trapezoid area are poured to a middle pilot tunnel vault at a time after a middle partition wall foundation is poured; main tunnel construction is conducted after a middle partition wall is poured; the triangular areas on the two sides of the wall top and a main tunnel primary support are subjected to integrated sprayed concrete backfill construction; steel floral tubes are adopted for supplementary grouting reinforcement; and pouring of the middle partition wall body and the wall top is completed. According to the invention, the problems that concrete of the wall cap of the middle partition wall is not vibrated compactly due to the fact that the construction space of the wall top is extremely limited in a conventional construction method, and the strength is insufficient are solved. The safety of main hole excavation construction is ensured. The integral structure formed by the middle partition wall and the main tunnel primary support is better in integrity. The risks of cracks and water leakage of the middle partition wall can be effectively reduced.

Owner:GUIZHOU HIGHWAY ENG GRP

Reinforced concrete-fiber reinforce plastic (FRP) pipe confined seawater sea sand recycled concrete combination column

InactiveCN110318497ASolving Corrosion ProblemsMeet the development requirementsArched girdersPortal framesFiberReinforced concrete

The invention discloses a reinforced concrete-fiber reinforce plastic (FRP) pipe confined seawater sea sand recycled concrete combination column. A seawater sea sand recycled concrete and an FRP material are combined, and a reinforcing steel bar is configured into a common recycled concrete so as to be prevented from being corroded, so that the problem of low rigidity of the FRP pipe confined seawater sea sand recycled concrete column can be solved, the crack propagation is effectively suppressed, the ductility and a bearing capacity of the reinforced concrete-FRP pipe confined seawater sea sand recycled concrete combination column can be further improved, and the occurrence of brittle fracture is avoided.

Owner:GUANGDONG UNIV OF TECH

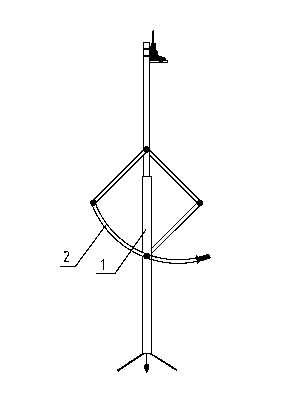

Hole drilling device for ceilings

InactiveCN104107931AGuaranteed to be straightImprove installation qualityWork benchesPortable drilling machinesInfraredEngineering

The invention provides a hole drilling device for ceilings. The hole drilling device for the ceilings mainly comprises a drawable vertical rod and a movable bent rod connecting piece. In a construction process, inconvenience caused by construction of a scaffold is greatly reduced; the hole drilling device is convenient to operate, and can be constructed in narrow space; the construction progress is increased; and the labor cost is saved. When the hole drilling device is used, a location on the ground is found out by infrared rays; the hole drilling device is positioned by using a pendant below equipment, is quick and convenient to operate and is positioned accurately; and straightness of mounting components can be effectively guaranteed. The hole drilling device for the ceilings is easy to manufacture, and is quick and easy to construct; the engineering cost is reduced; and the popularization and application value is high.

Owner:QINGDAO NO 1 CONSTR GRP

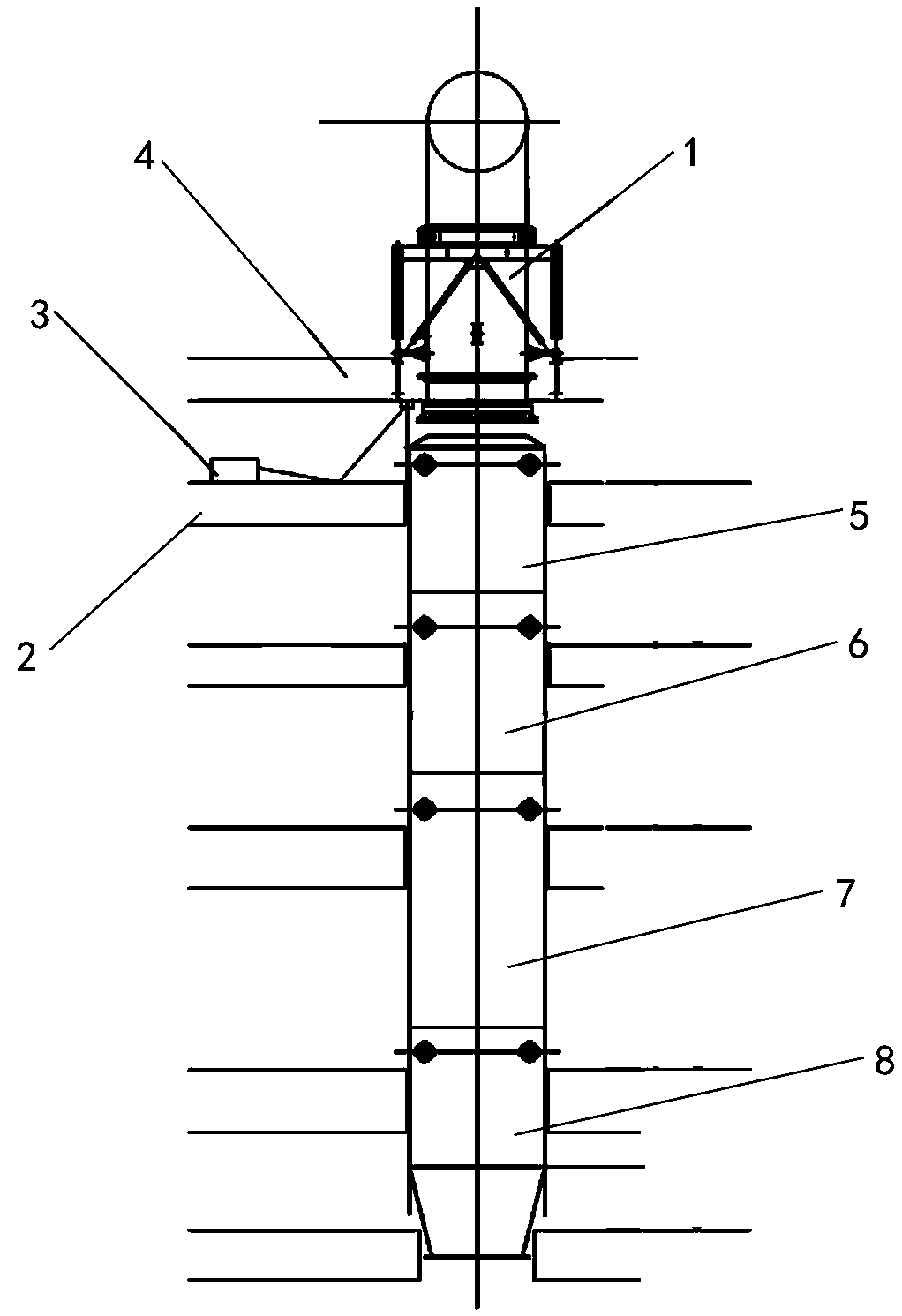

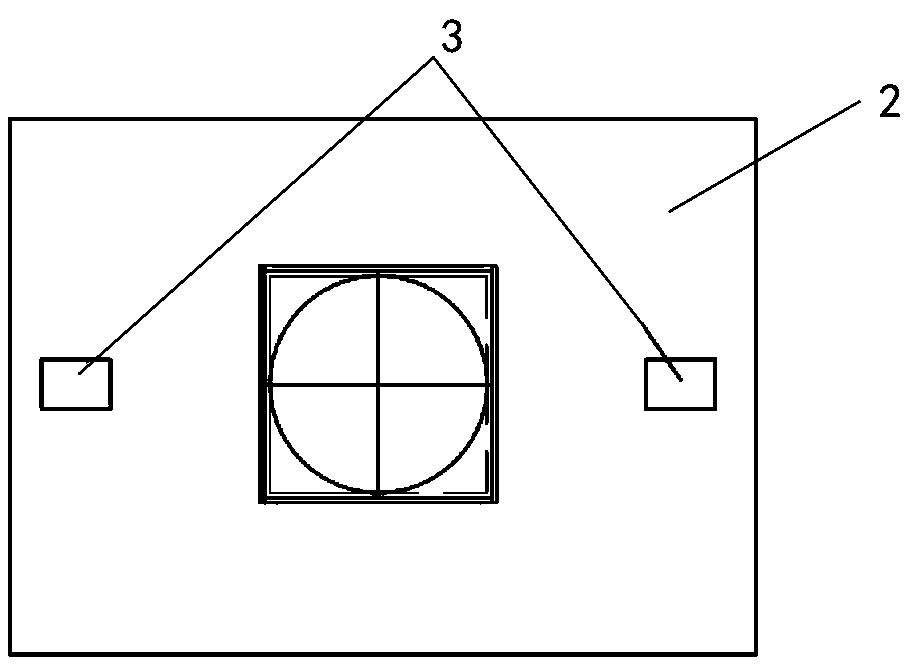

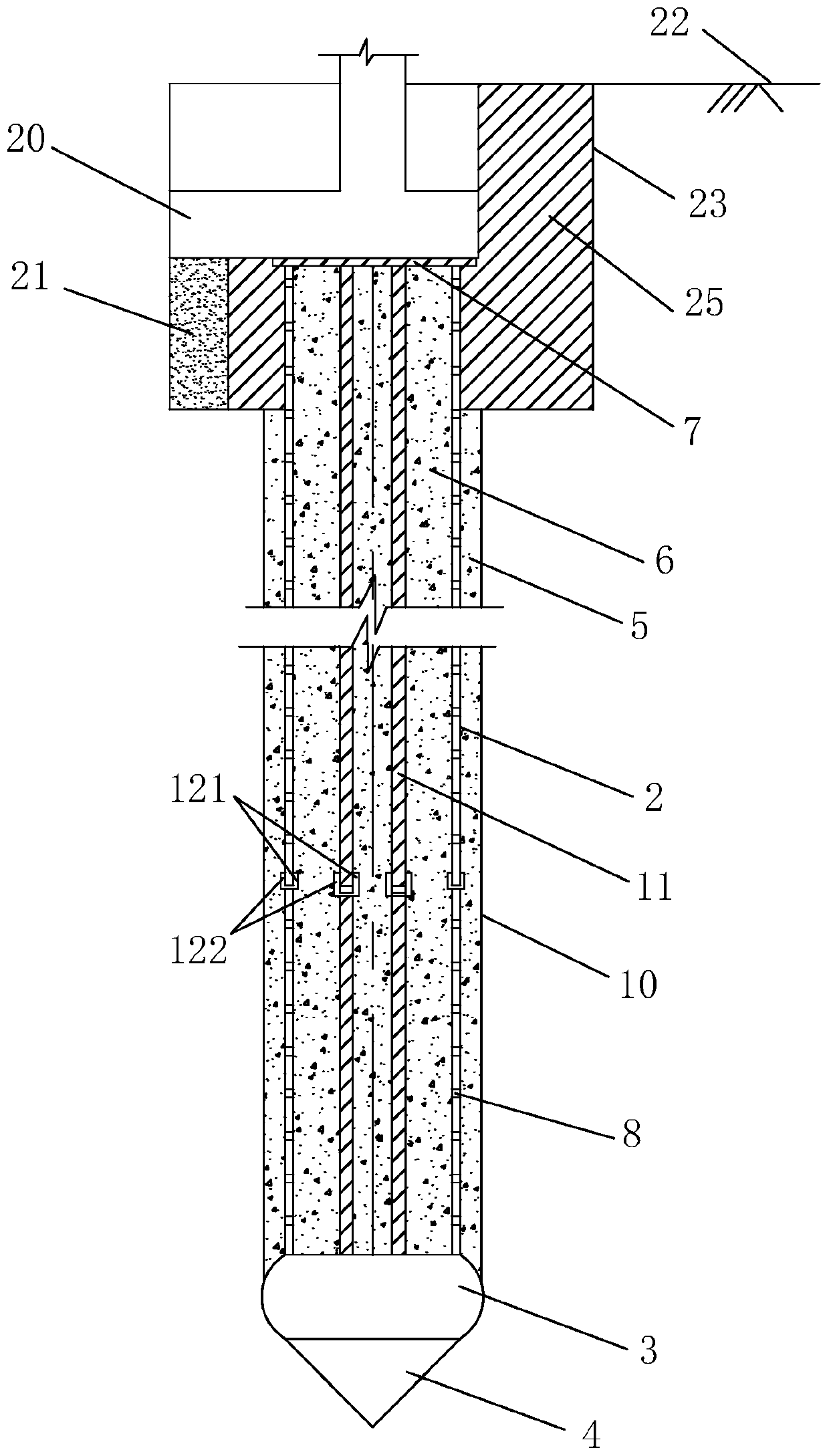

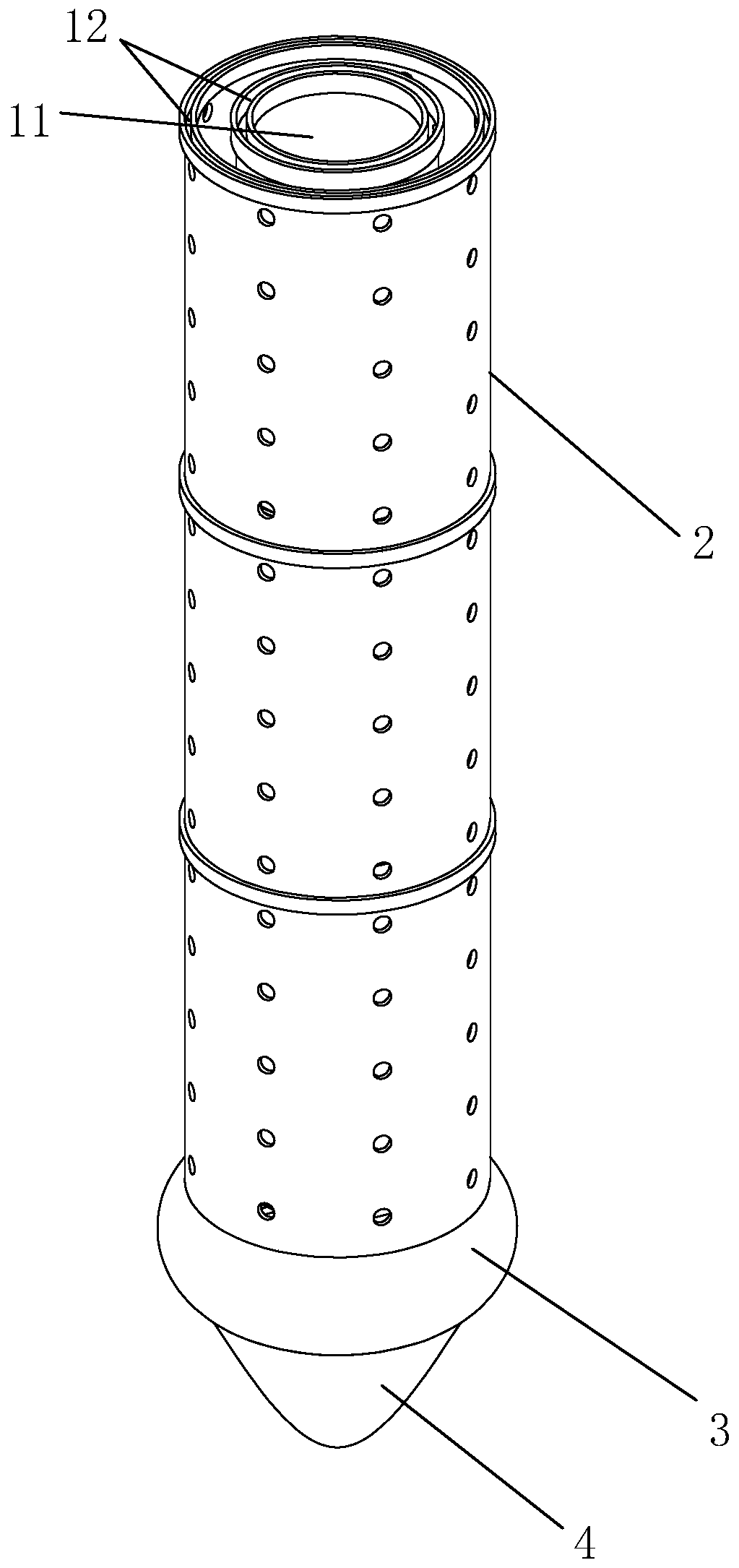

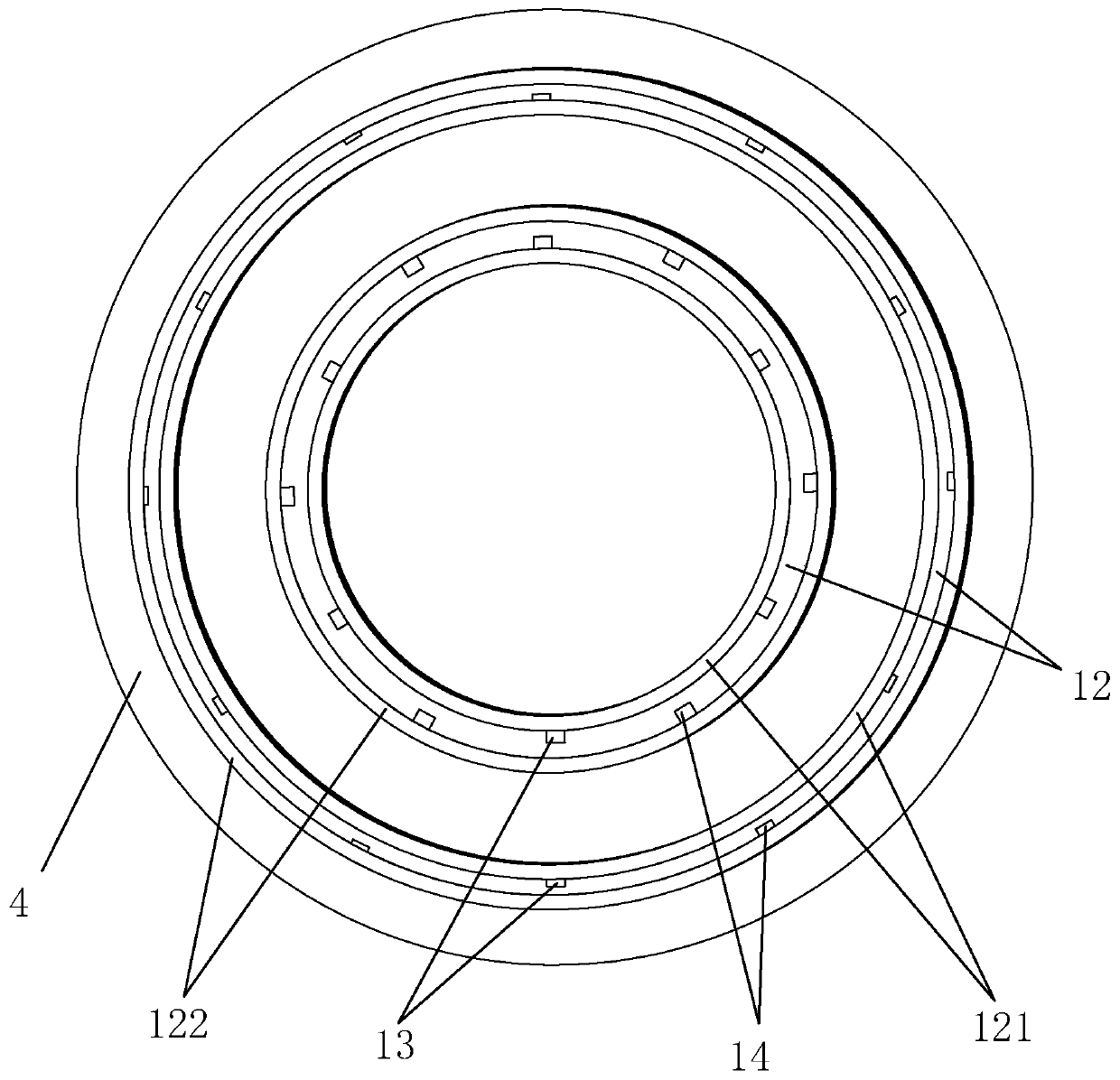

A construction device and method for concrete pipe piles

ActiveCN111733797BReduce the difficulty of operationReduce security risksLighting elementsBulkheads/pilesArchitectural engineeringStructural engineering

Owner:THE ELEVENTH METALLURGICAL CONSTR GRP

A kind of installation method of large tank body

ActiveCN110077963BReduce the difficulty of construction operationsReduce construction costsLoad-engaging elementsWinchIndustrial engineering

The invention relates to a method for installing a large tank body. The installation step is to install hoists on the uppermost workshop platform through which the tank body to be installed will pass through. There are at least two hoist machines, which are symmetrically installed on both sides of the tank body to be installed. ; Then pass the traction rope of the winch through the point of stress and let the rope down until it reaches the ground; hoist the tank to be installed in sections from top to bottom: weld the two sides of the first section of the tank at the top One lifting lug, use rigging to fix a section of steel wire rope on the corresponding lifting lug, then connect the steel wire rope to the traction rope of the winch and start hoisting; after the hoisting of each tank body is completed, weld the adjacent two tank body counterparts . The present invention utilizes the existing platform in the workshop to carry out the installation operation, and has the advantages of not using a crane for lifting operations, occupying a small area of the site, not affecting production, low operation difficulty, and high safety factor, and is worthy of popularization and application in metallurgical construction projects.

Owner:CHINA MCC20 GRP CORP +1

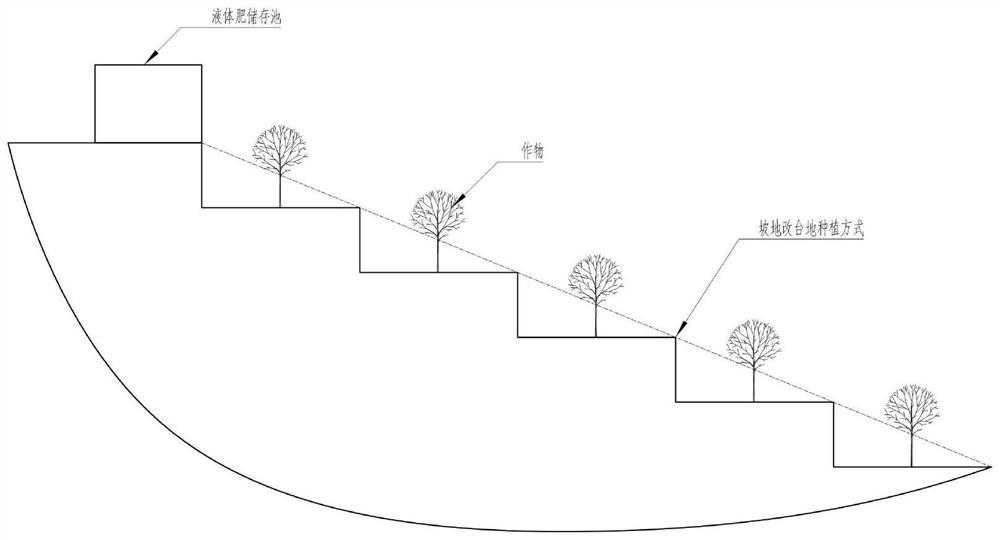

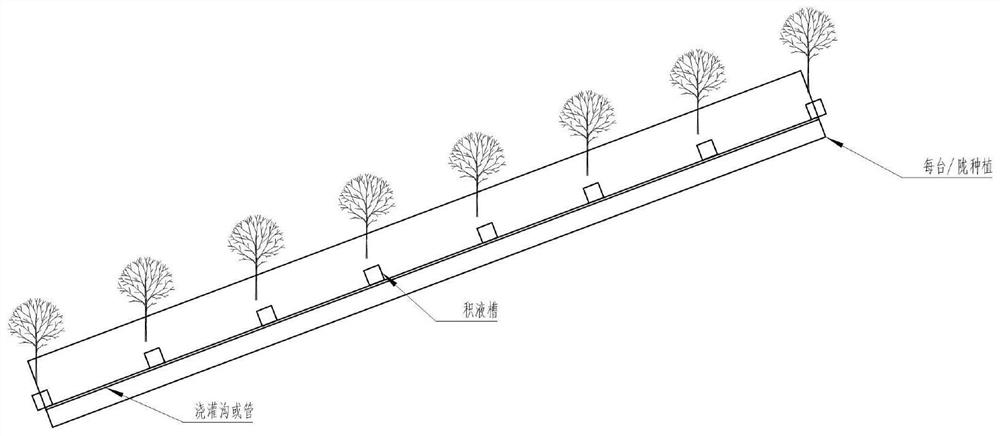

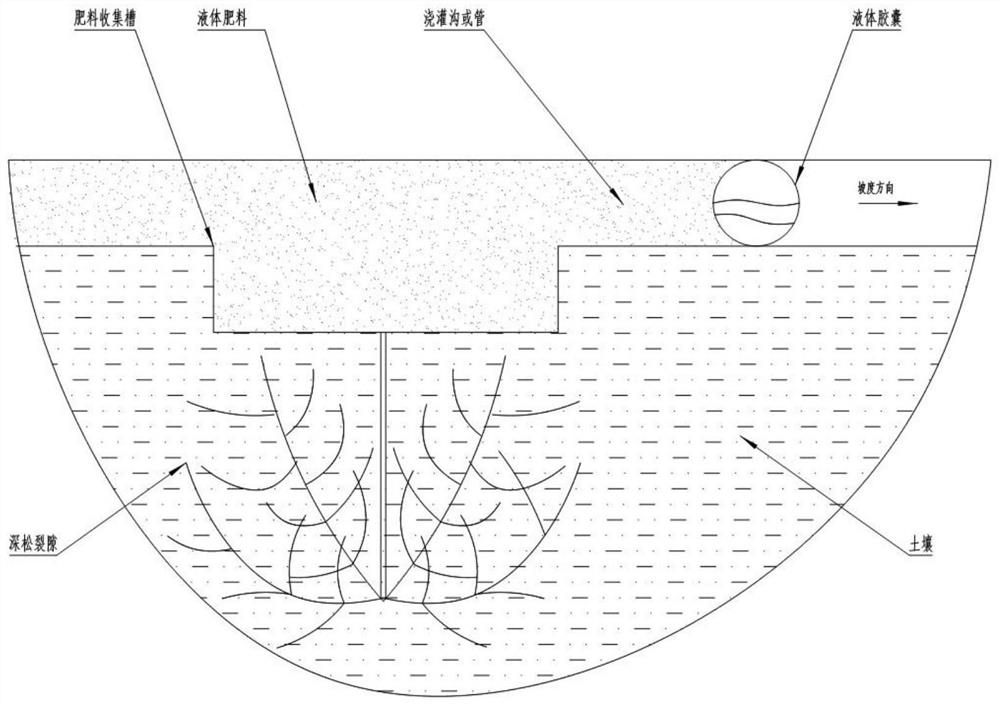

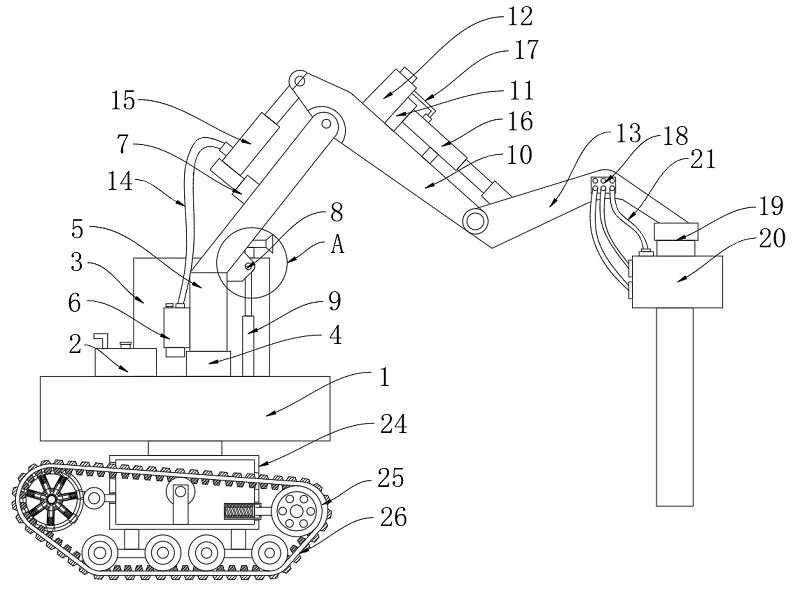

Self-flow type shock wave spray explosion deep scarification and deep application operation method suitable for liquid fertilizer

PendingCN114731817AIncrease profitReduce handlingGravity flow based distributionAgriculture gas emission reductionSoil scienceAgricultural engineering

The invention provides a self-flowing type shock wave spray-explosion deep scarification and deep application operation method suitable for liquid fertilizer, which is characterized in that a self-flowing type shock wave spray-explosion deep scarification and deep application operation system is constructed according to natural landforms, and self-flowing type precise deep application of the liquid fertilizer is realized through the self-flowing type shock wave spray-explosion deep scarification and deep application operation system. The self-flowing type deep application operation system comprises a fertilizer storage device, a fertilizer conveying device, a fertilizer collecting device and a fertilizer deep application channel; and the fertilizer storage device is used for storing liquid fertilizer. According to the method, natural landforms can be well utilized, self-flowing type deep application operation in high mountains or hills and other zones is achieved, a large amount of labor force and complex machines are not needed, high deep application operation cost is not needed either, and the utilization rate of fertilizer is greatly increased.

Owner:CHENGDU TOBEST DIYUAN TECH CO LTD

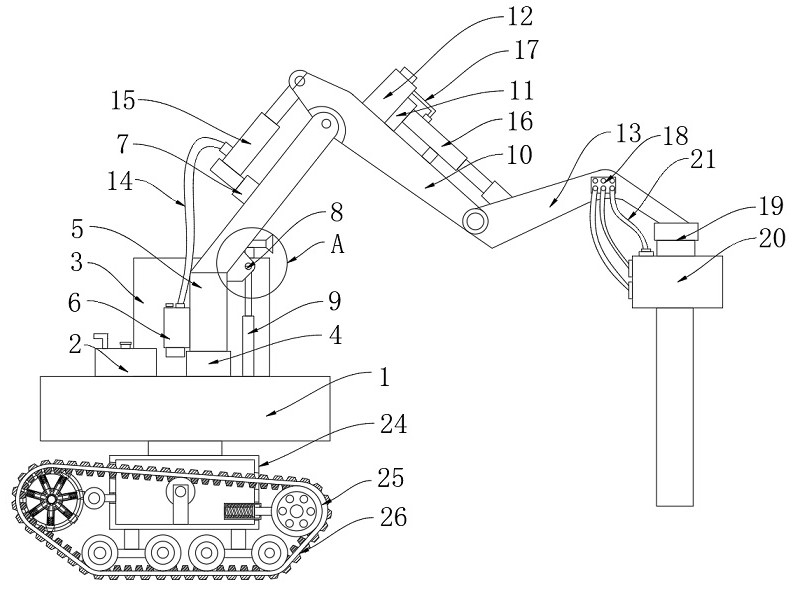

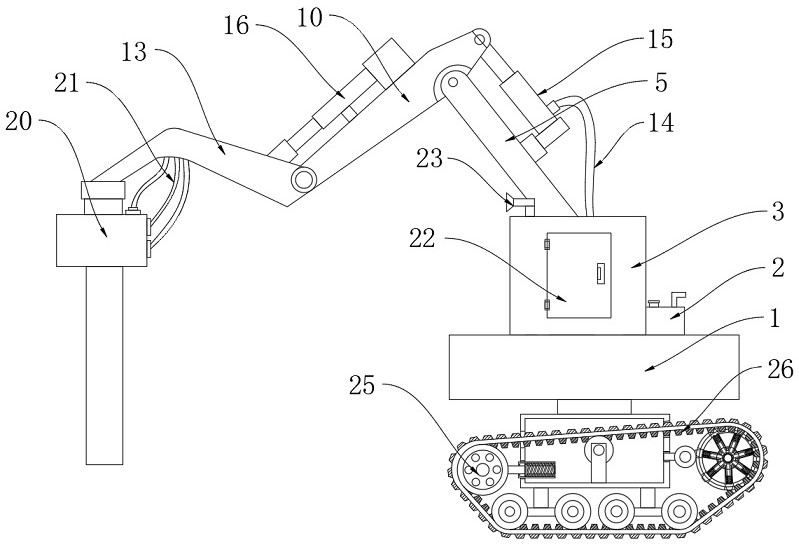

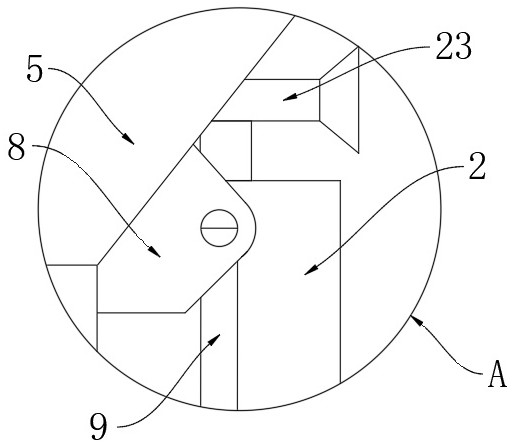

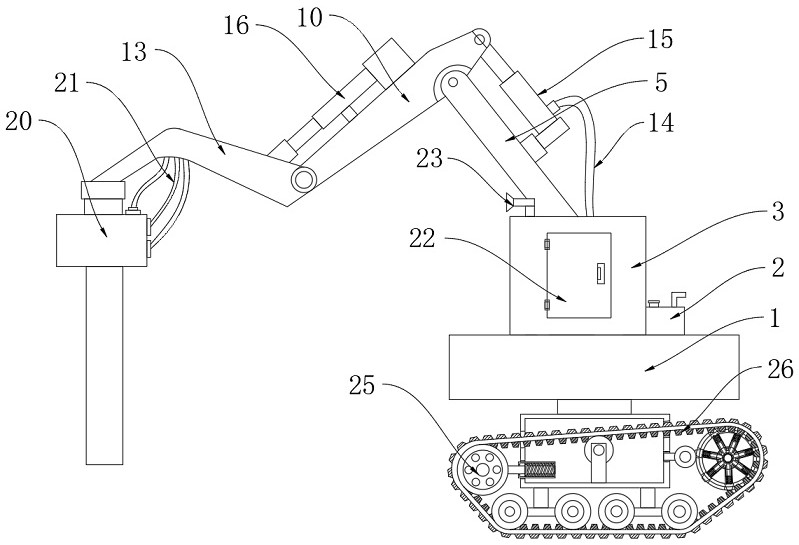

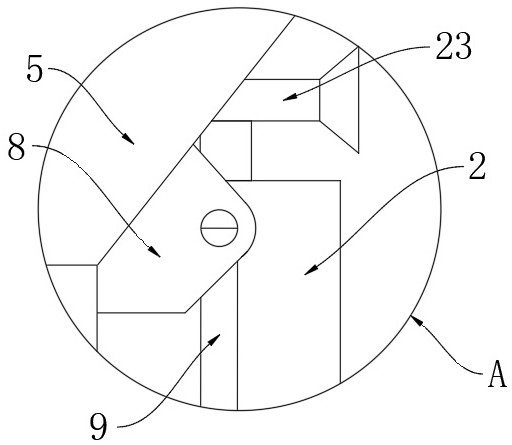

Construction device and method for concrete pipe pile

ActiveCN111733797AReduce the difficulty of operationReduce security risksLighting elementsBulkheads/pilesArchitectural engineeringStructural engineering

The invention discloses a construction device for a concrete pipe pile. The construction device comprises a control machine body. A metal water tank, an operation control chamber and a rectangular block are fixedly connected to the upper surface of the control machine body. A rectangular opening is formed in the upper surface of the rectangular block, and a first metal shaft is fixedly connected to the inner wall of the rectangular opening. The invention further provides a construction method for the concrete pipe pile. The construction method for the concrete pipe pile comprises the followingsteps of S1, firstly opening a protective door to enter an operation control room, and starting equipment. According to the construction device for the concrete pipe pile, through the arrangement ofa first transmission rod, a second transmission rod, a third transmission rod and a pile cutting rack, multiple tools are not needed for auxiliary operation when the device is used for constructing the concrete pipe pile, manual auxiliary operation is reduced during construction, and potential safety hazards of accidents are reduced. The device has the advantages that auxiliary operation of the multiple tools is not needed, the construction operation difficulty is reduced for people, dangerous accidents can be reduced, and safety accidents are avoided.

Owner:THE ELEVENTH METALLURGICAL CONSTR GRP

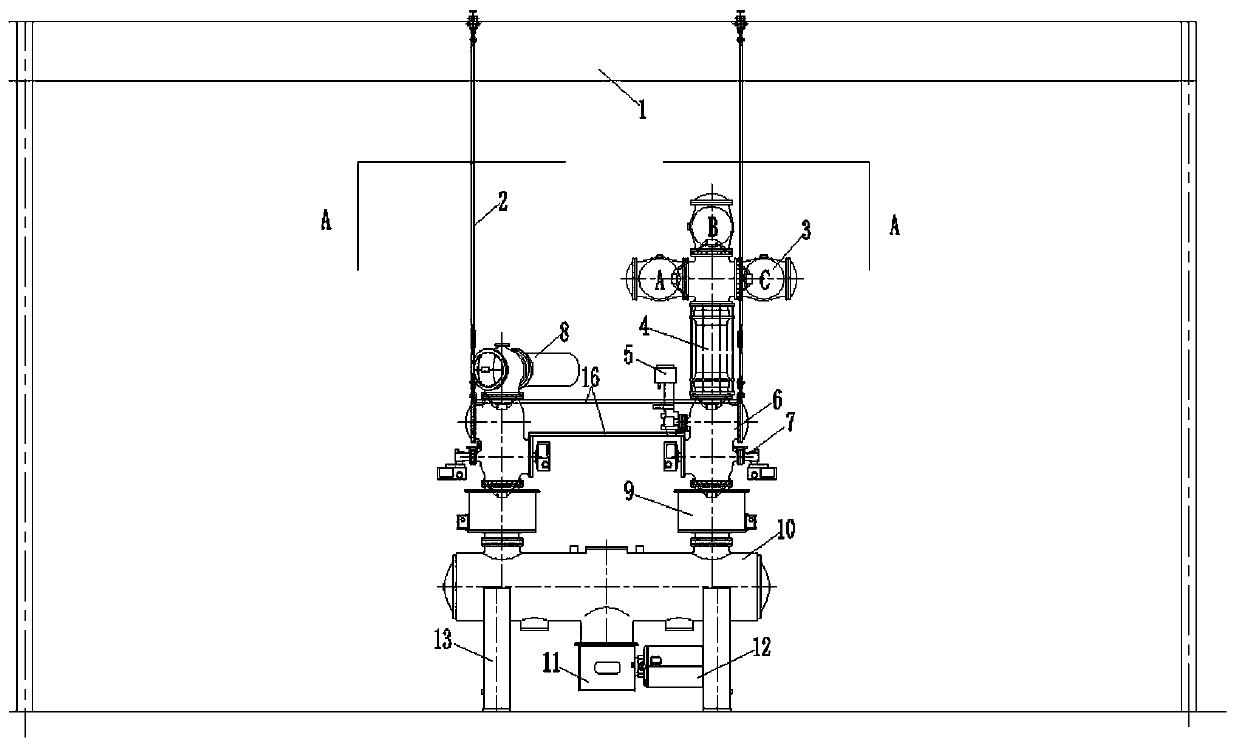

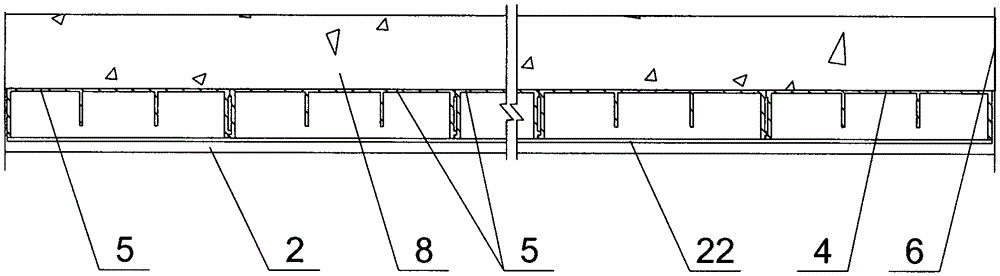

Pushing method and device for middle span of prestressed concrete box girder continuous rigid frame bridge with long span and high pier

ActiveCN105926454BReduce unevennessReduce the difficulty of construction operationsBridge erection/assemblyPre stressMesh reinforcement

The invention discloses a mid-span jacking method and device for a prestressed concrete box girder continuous rigid frame bridge with long-span and high pier, which comprises a combined I-shaped steel girder, a backing plate, a welded steel plate, a combined H-shaped steel girder, a jack, Stiff skeleton; the combined I-shaped steel beam is welded by two I-shaped steel beams side by side, the combined H-shaped steel beam is welded by two H-shaped steel beams side by side, and the two ends of the box girder are vertical The combined I-shaped steel beams are directly buried, and the buried depth is 1 / 2 of the length of the web. Both sides of the steel mesh are welded to one end of the stiff frame along the longitudinal direction of the bridge, and the opposite stiff frames on both sides are on the same axis. The present invention directly installs the jacking device on the top of the box girder roof and pushes it, which greatly reduces the difficulty of construction operation, and can better ensure the quality of the jacking, the installation is simple and fast, and the preparation time for jacking is saved, thereby shortening the construction period and reducing the cost of construction. small cost.

Owner:SHANDONG UNIV OF SCI & TECH

GIS body equipment technical transformation construction method

ActiveCN111404066AReduce the scope of outagesReduce security risksSwitchgearOperation safetyIndustrial engineering

The invention discloses a GIS body equipment technical transformation construction method. The technical transformation power failure range can be reduced, the power failure time and construction period are shortened, the equipment disassembly and assembly work amount and the construction operation difficulty are reduced, and the operation safety and quality risks are reduced. Construction can becarried out in stages according to different positions of elements needing to be replaced on each string of GIS body equipment, and the flexibility and convenience of GIS transformation work are improved.

Owner:CHINA YANGTZE POWER +1

Construction method of technical transformation of gis body equipment

ActiveCN111404066BReduce the scope of outagesReduce security risksSwitchgearOperation safetyIndustrial engineering

The construction method of technical transformation of GIS body equipment can reduce the scope of technical transformation power outages, shorten the power outage time and construction period, reduce the amount of equipment disassembly and assembly and the difficulty of construction operations, and reduce the risk of operation safety and quality. Using this construction method can be based on each series of GIS body The components that need to be replaced on the equipment are constructed in different positions, which increases the flexibility and convenience of the GIS transformation work.

Owner:CHINA YANGTZE POWER +1

A two-way self-supporting building formwork system

ActiveCN103216087BReduce distortionImprove the uniformity of forceForms/shuttering/falseworksEngineeringVolumetric Mass Density

The invention discloses a bilateral self-bearing building template system, which has the advantages of material saving, high construction efficiency, good bearing effect and long service life. The system further has the advantages of no pin connection, difficulty in deformation, capabilities of increasing the turnover use efficiency and reducing processing and installing workloads, convenience in early detachment, easiness and convenience in operating, practicability, effective increase in the seam density of a template and improvement on the concrete forming effect. The system comprises support column assemblies (1), bearing beams (2) and bearing plates (3), wherein the bearing beams (2) are connected with the support column assemblies (1) to construct a plurality of single-direction main beams; the bearing plates (3) are distributed among the single-direction main beams, and construct a template system plate surface together with the single-direction main beams; beam lugs (22) are arranged on the lower parts of the side faces (21) of the bearing beams (2); the two ends of the bearing plates (3) are overlapped on the beam lugs (22); two side plates (31, 32) of the bearing plates are provided with plate lugs (311, 321); adjacent bearing plates (3) are matched and overlapped through the plate lugs (311, 321); and the top plates (30) of the bearing plates (3) are flush with the top surfaces (20) of the bearing beams (2). The system can be applied to the field of building templates.

Owner:FOSHAN GUANGYA ALUMINUM FORMWORK SCI & TECH

Suspender mounting device and use method thereof

InactiveCN110528831AImprove securityImprove construction efficiencyBuilding constructionsArchitectural engineeringBuilding construction

The invention relates to the technical field of building construction auxiliary tools, in particular to a suspender mounting device and a use method thereof. A vertical pipe is fixed to a horizontal pipe, a sleeve head with the inner cavity shape matched with the appearance of a fixed nut of a suspender is fixed to the vertical pipe, one side of the sleeve head is provided with a screw with the width larger than the suspender, and a vertical gap smaller than the outer diameter of a nut, the screw of the suspender can be put in or taken out, a constructor can directly stand on the ground for constructing mounting of the suspender without tools such as a scaffold or a climbing ladder, safety during construction is improved, the construction operation difficulty is reduced, construction efficiency is improved, and the good economy and popularization are achieved.

Owner:MCC5 GROUP CORP SHANGHAI

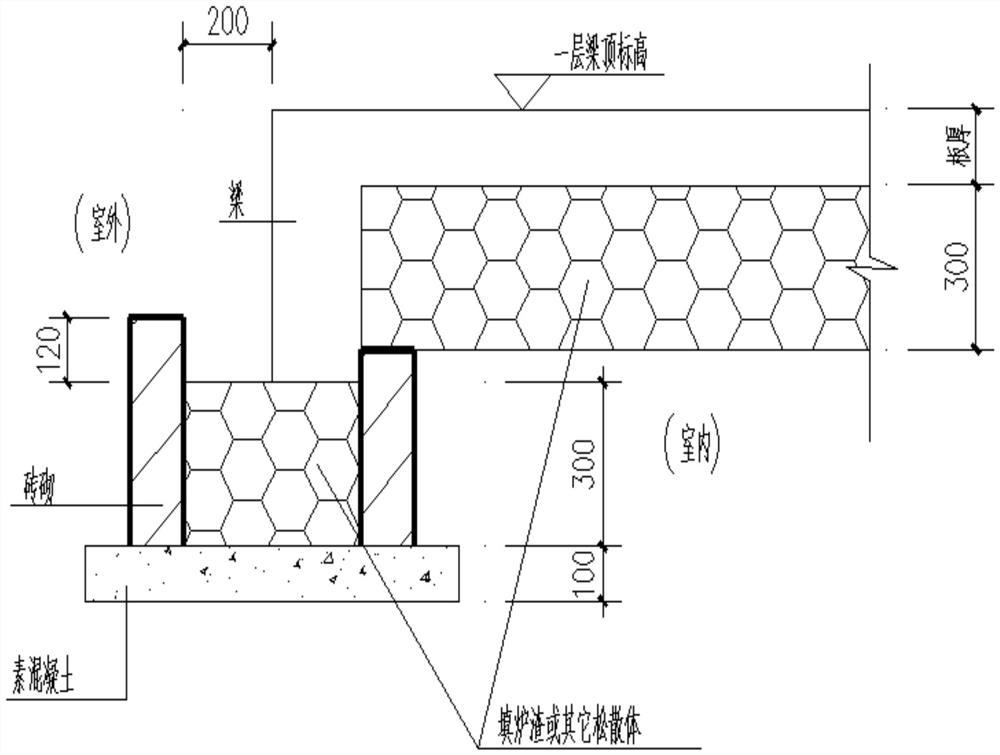

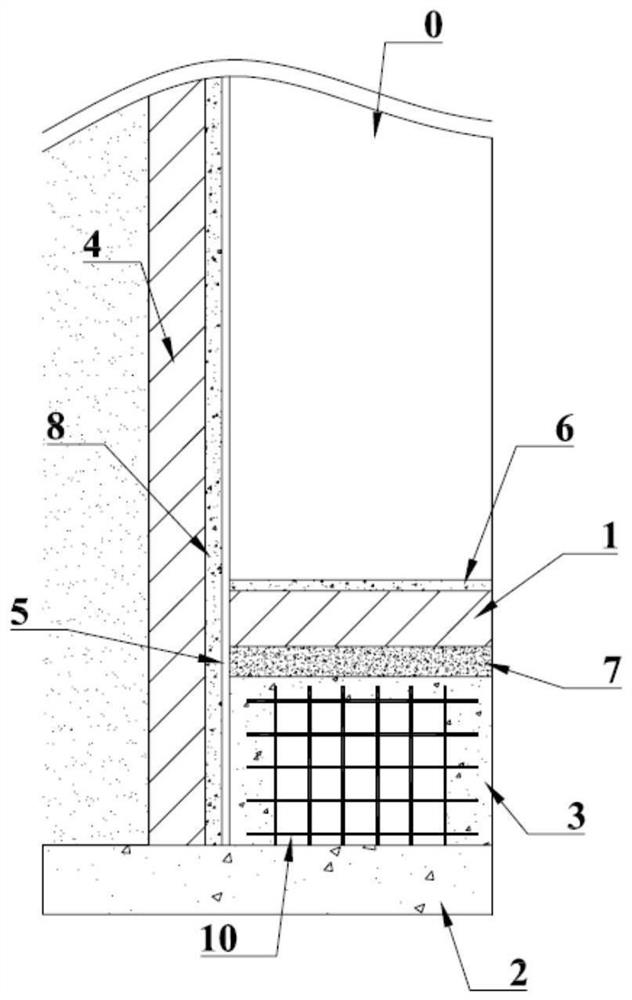

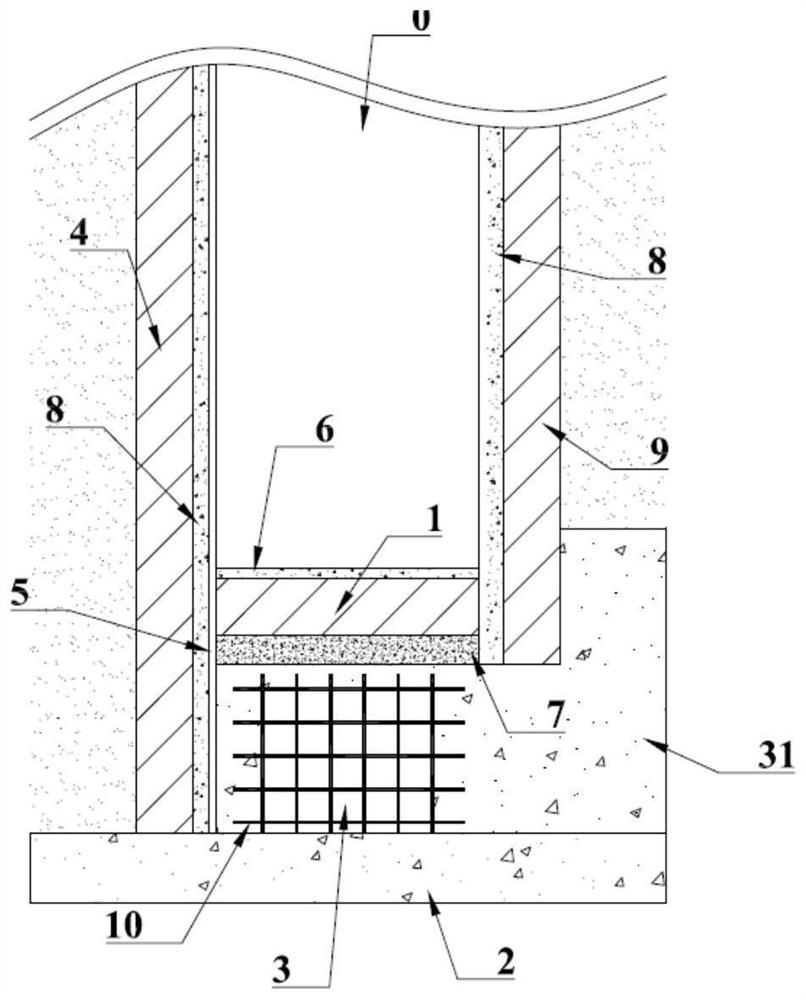

Building boundary beam frost heaving prevention structure and construction method thereof

ActiveCN114197542AOvercoming the defects of excessive frost heaveReduce or avoid the effectProtective foundationInsulation layerPolystyrene

The invention relates to a building boundary beam frost heaving prevention structure which comprises a beam bottom heat preservation layer, a cushion layer, a filling layer, a beam outer heat preservation layer on the outer side of a boundary beam and an asphalt isolation layer, the beam bottom heat preservation layer is arranged on the bottom face of the boundary beam, the cushion layer is arranged on the bottom face of an excavation pit, and the space between the beam bottom heat preservation layer and the cushion layer is filled with the filling layer; the asphalt isolation layer is arranged on the outer side of an integral structure formed by the edge beam, the beam bottom heat preservation layer and the filling layer, and the beam outer heat preservation layer is arranged on the outer side of the asphalt isolation layer; the beam bottom heat preservation layer and the beam outer heat preservation layer are both polystyrene foam extrusion molding heat preservation plates. The invention further relates to a construction method of the building boundary beam frost heaving prevention structure. According to the structure, the heat preservation layers are arranged on the beam bottom and the outer side of the beam, the effect of foundation soil frost heaving force on the foundation boundary beam is reduced or avoided, and on the basis that the construction efficiency and quality are improved, the construction cost is reduced, and the construction period is shortened.

Owner:新疆博际建筑工程有限责任公司

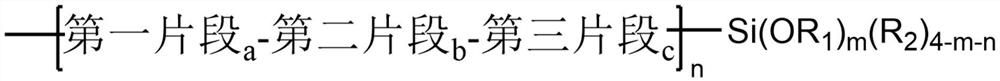

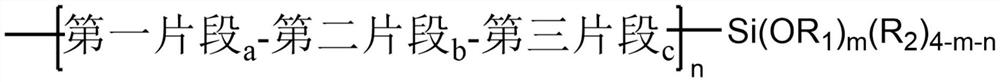

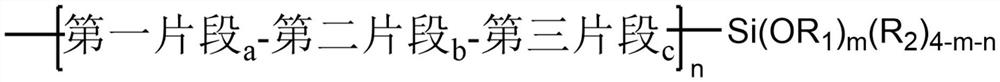

Hydrolyzable polymer and epoxy resin heat-conducting material composition containing same

ActiveCN114213648AGood compatibilityRaise the side chainGroup 4/14 element organic compoundsChemical industryEpoxyPolymer science

The invention belongs to the technical field of composite material processing, and particularly relates to a hydrolyzable polymer, which has the following structural formula: a first fragment, a second fragment and a third fragment are respectively selected from one of an alkyl chain, an aromatic part and a polyether chain, are different from one another and are randomly arranged, and the first fragment, the second fragment and the third fragment are different from one another and are different from one another. Wherein a, b and c are integers between 0 and 10 and are not 0 at the same time, m and n are integers between 1 and 3, and m + n is less than or equal to 4. The invention has the following beneficial effects: the raw material cost is low, the problem of poor stability of common treatment agents is solved, the precipitation phenomenon of conventional hydrolyzable series dispersants or silane coupling agents is serious in the use process, precipitation of a large amount of organic matters on the surface of a mixture can be observed within 24 hours, and the treatment effect is good. The hydrolyzable polymer can prolong the stability period of the composite material to 1-6 months, so that the storage stability and the production efficiency are greatly improved.

Owner:安徽壹石通材料科学研究院有限公司

Reinforcement structure of building foundation and construction method thereof

ActiveCN108999227BReduce frictional resistanceReduce the difficulty of construction operationsFoundation repairBulkheads/pilesArchitectural engineeringCement slurry

Owner:中核四达建设监理有限公司

High-voltage electrical device grounding system on multi-layer steel structure platform and arrangement method

PendingCN111628303AReduce dosageReduce in quantityConnection contact member materialGrounding gridMaterial consumption

The invention provides a high-voltage electrical device grounding system on a multi-layer steel structure platform and an arrangement method, wherein the system comprises grounding ring network flat copper disposed on each layer of steel platform, each layer of grounding ring network flat copper is connected with a corresponding grounding downlead flat copper through a first silver-copper weldingspot in a welding or bolted manner, each grounding downlead flat copper is led to a steel platform supporting leg grounding downlead along a steel platform stand column, and the steel platform supporting leg grounding downleads are connected with an underground concealed grounding network. According to the invention, the material consumption, the installation work amount and the construction operation difficulty of the high-voltage electrical device grounding system on the multi-layer steel structure platform can be reduced, the construction period is shortened, the load of the steel structureplatform is reduced, the operation safety and the quality risk are reduced, and the grounding wire arrangement is concise and beautiful.

Owner:CHINA YANGTZE POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com